Thin transformer and transformer component

一种变压器、薄形化的技术,应用在变压器领域,能够解决厚度难以再缩减等问题,达到增加弹性应用的空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

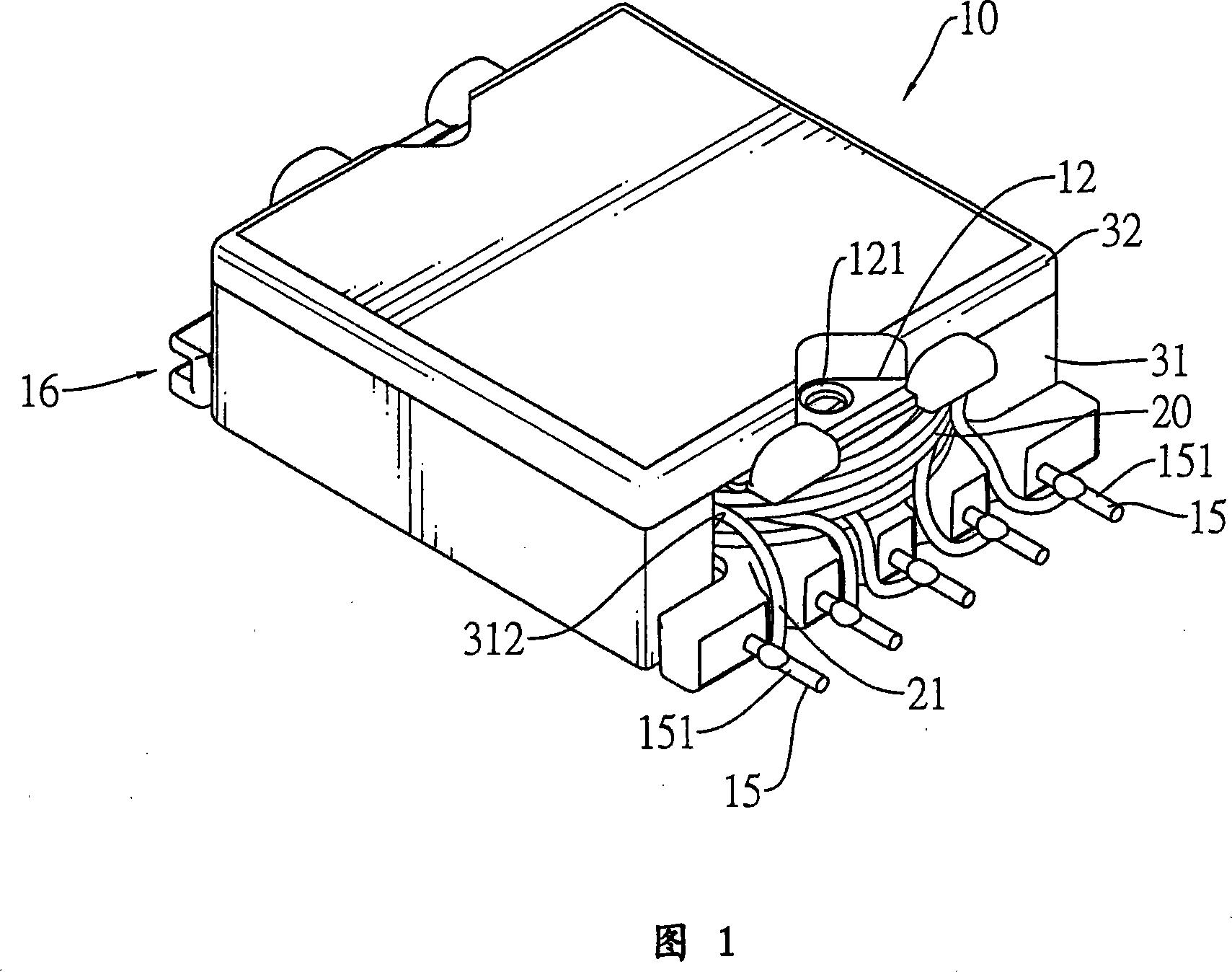

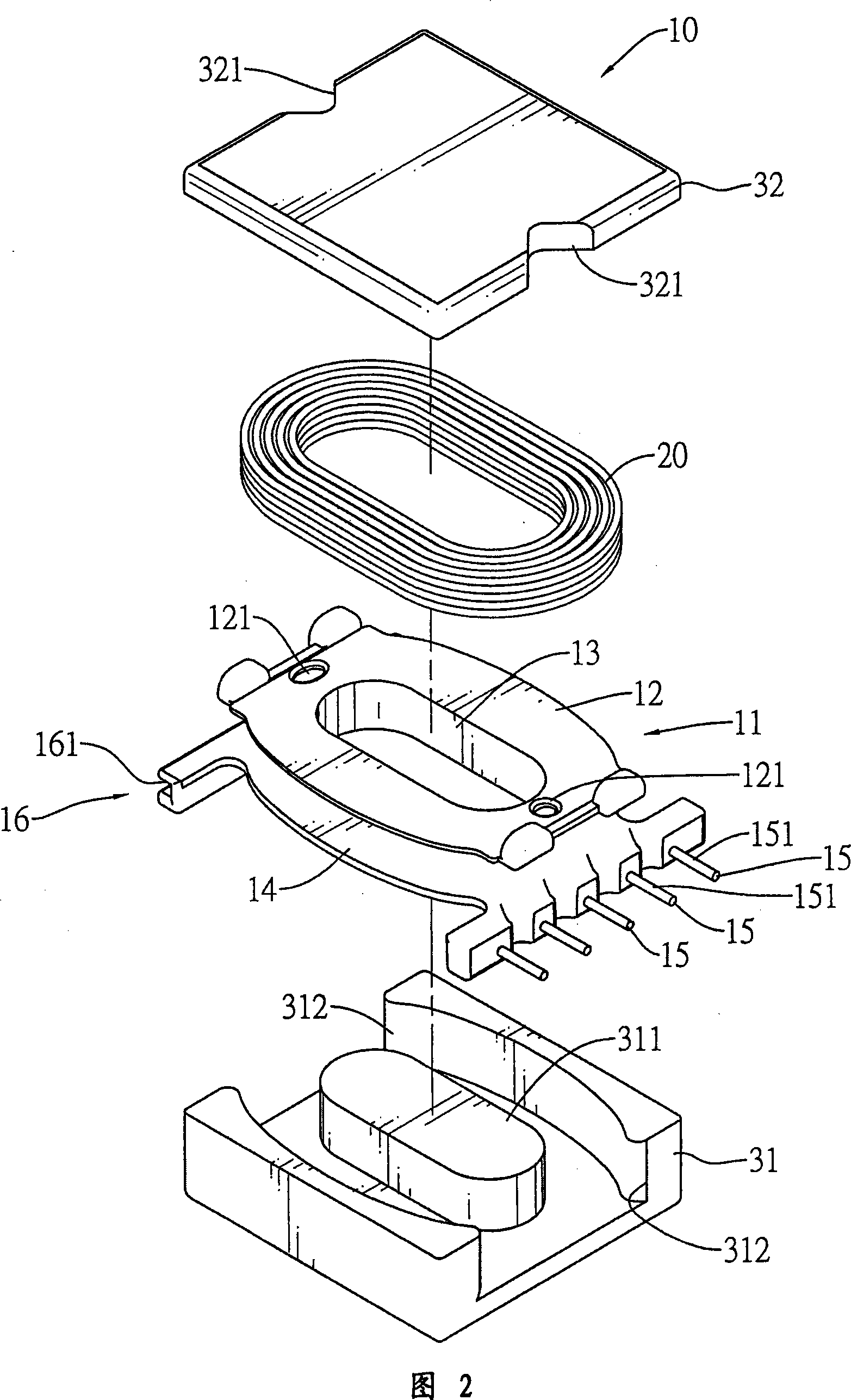

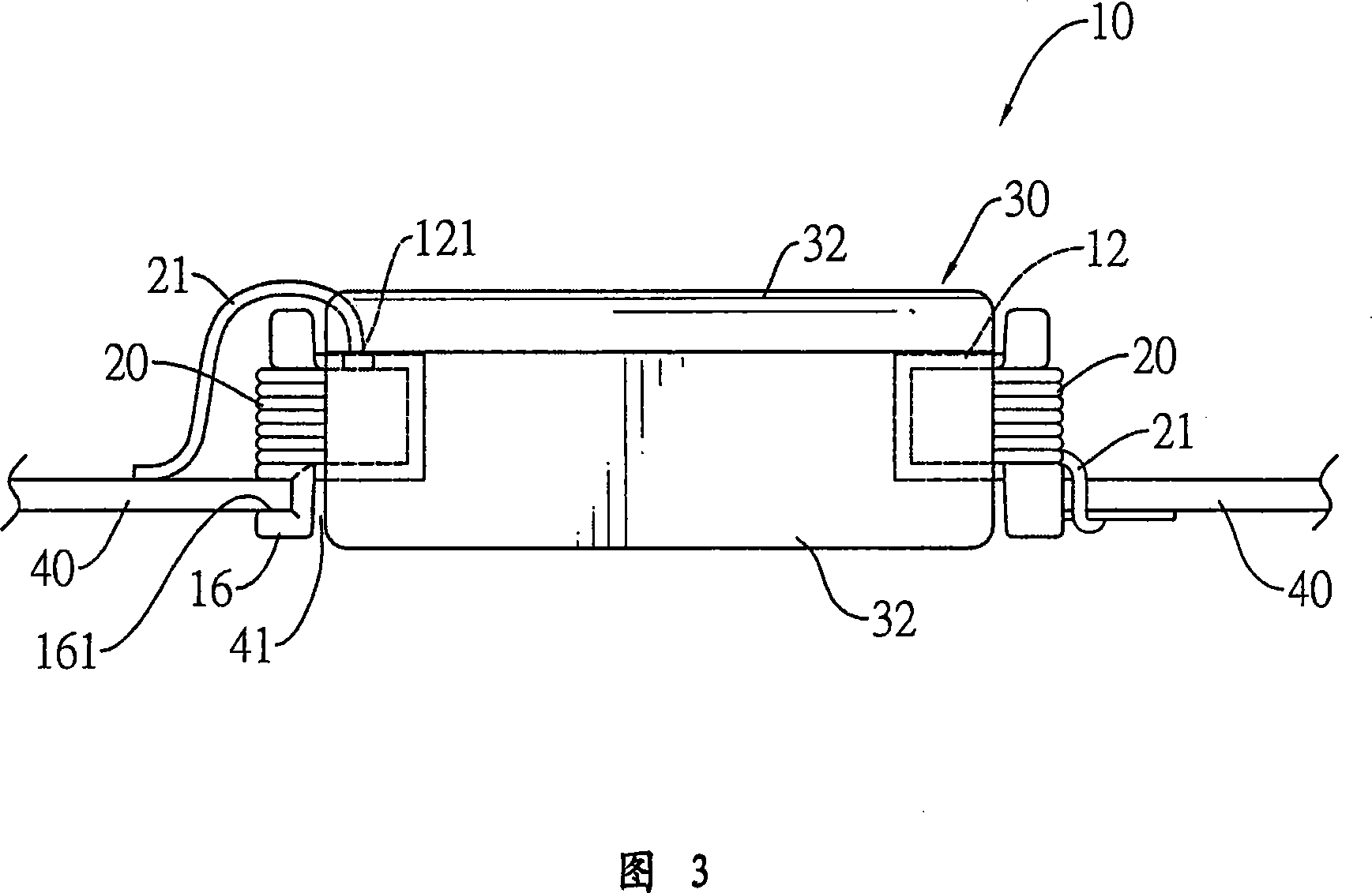

[0024] First please refer to Figures 1 and 2, which are the first preferred embodiment of the thin transformer 10 of the present invention, which includes:

[0025] The wire frame 11 has an I-shaped section and is composed of an upper ring 12, a hollow column 13 and a lower ring 14, wherein at least one side of the lower ring 14 is horizontally provided with a plurality of pins 15, and the upper end surface of each pin is a welding surface 151; and the two opposite sides of the upper ring 12 are respectively formed with wire holes 121; in this embodiment, one side of the lower ring 14 is provided with a plurality of pins 15, and the other opposite side is provided with a connecting piece 16, The coupling part 16 is a clamping part, and its outer surface forms an embedded groove 161 inwardly;

[0026] The coil 20 is wound on the outer wall of the hollow column 13 of the wire frame 11, and part of the coil end 21 is connected to the corresponding pin 15. As shown in FIG. The wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com