Malodor reduction patch

A patch and deodorant patch technology, which is applied in the field of preparing the patch, can solve the problems of difficult control, easy to dirty, large volume and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

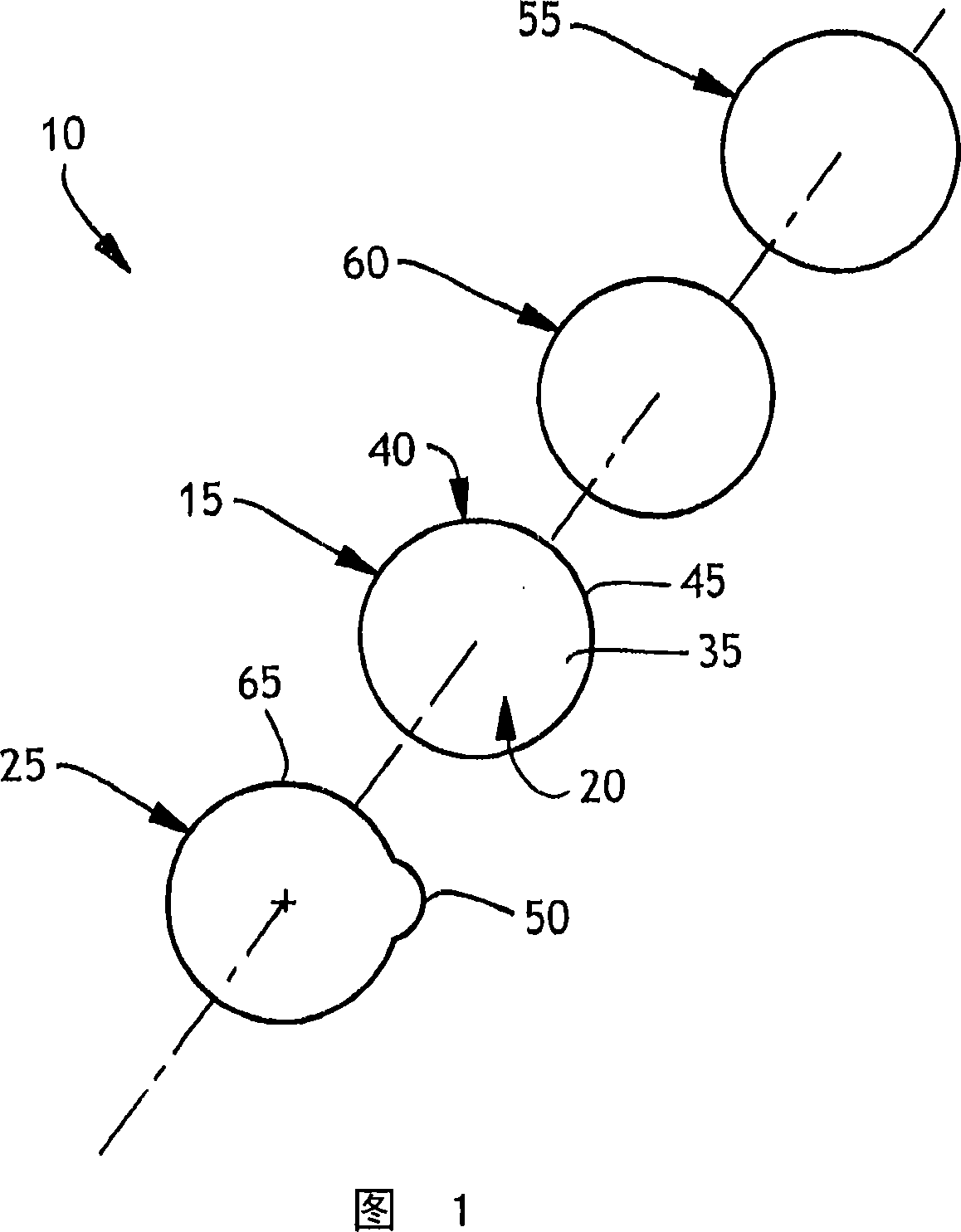

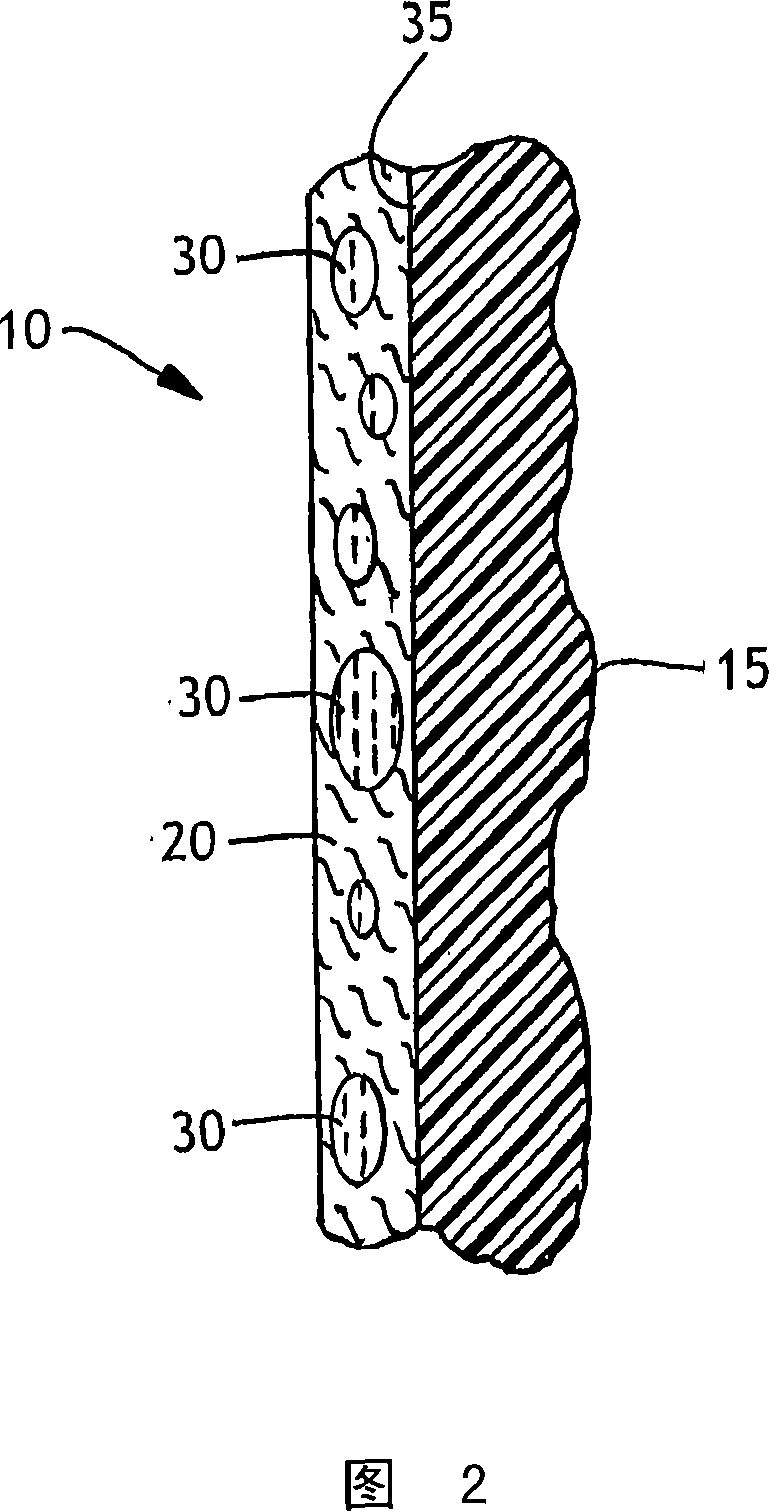

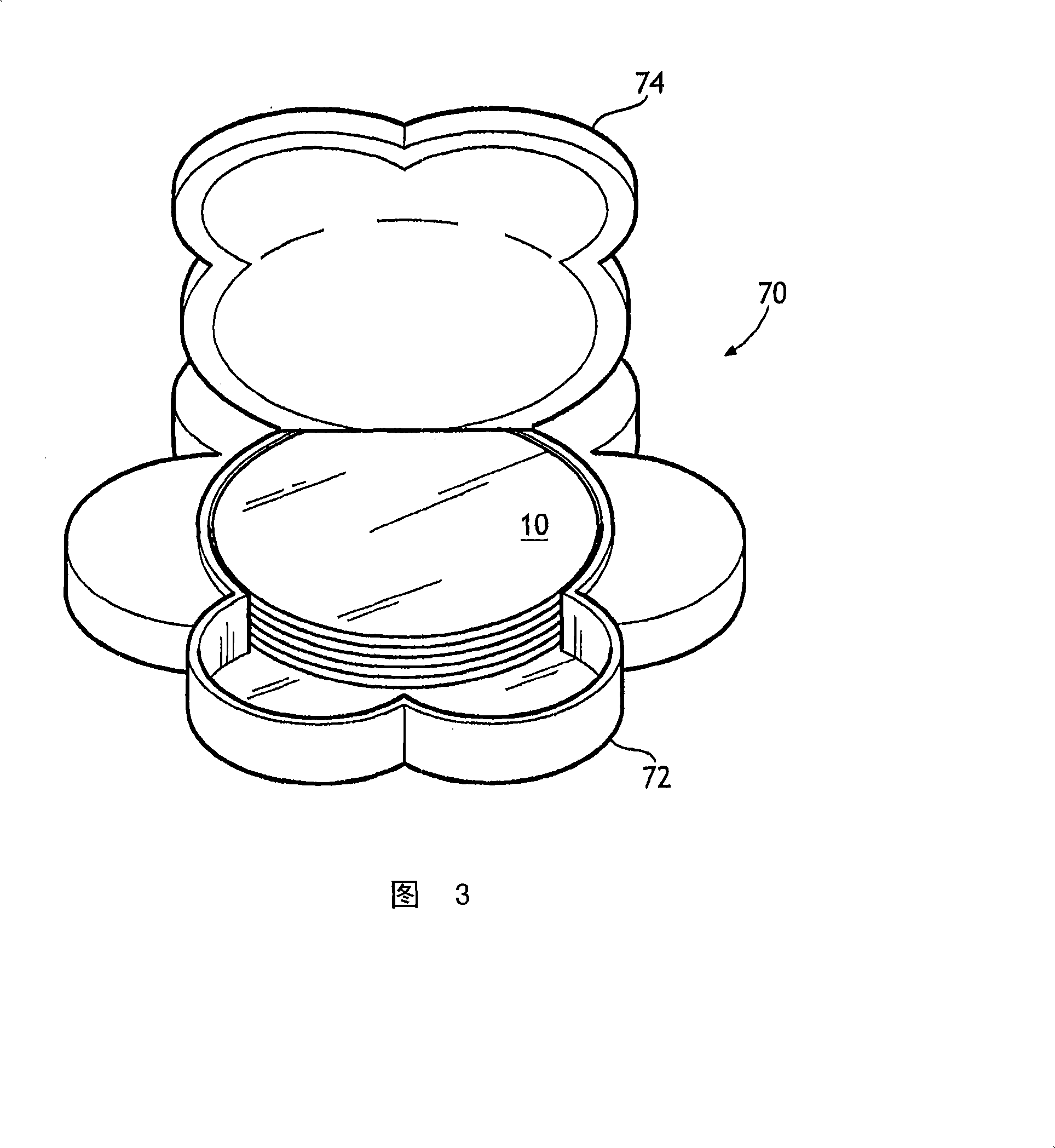

[0068] In an embodiment of one aspect of the invention, a plurality of washable patches 10 is prepared. The backsheet 15 is made from a 40 gsm breathable polymeric film, 68 mm wide, available from ZiHua Shanghai, Swanson. The protective layer 55 is made of 85 gsm hydroentangled fabric with a slit width of 70 mm, which is commercially available from Fujian Nanfang Textile Co., Sandler, Germany. Backsheet 15 was bonded to protective layer 55 using Easy Melt #34-5610 structural adhesive available from National Starch. The adhesive 20 takes the form of Dispoment #570-5504 sold by National Starch and is applied to the adhesive surface 35 of the backsheet 15 . The release layer 25 was made of blue printed base paper sold by Jiangshu Taoshi Paper Company, base weight 45gsm, width 66mm, and bonded to the adhesive 20 on the adhesive surface 35 . Each of the fragrances, Dandelion Breeze w / Jasmine available from Givaudan, Totally T available from Givandan, Smoothing available from Firm...

Embodiment 2

[0070] In an embodiment of one aspect of the present invention, a large number of washable patches 10 are produced. The washable backsheet 15 is made of 1 mil polyethylene sheet, 68 mm wide, commercially available from Pliant Corporation, Wisconsin, USA. The protective layer 55 is supported by 0.4 osy spun yarns with a 70 mm seam width, commercially available from Kimberly-Clark Corporation, Wisconsin, USA. The backsheet 15 was bonded to the protective layer 55 using Easy Melt #34-5610 structural adhesive sold by National Starch. The adhesive 20 takes the form of Easy Meltt #34-5602 sold by National Starch and is applied to the adhesive surface 35 of the backsheet 15 . The release layer 25 is made from a 66 mm wide coextruded polypropylene release tape sold by Huthamaki and bonded to the adhesive 20 on the adhesive surface 35 . Apply Firmenich FreshLinen fragrance to the patch. Each of the resulting patches 10 was applied to garments after removing the release tape therefro...

Embodiment 3

[0072] In an embodiment of one aspect of the present invention, a large number of washable patches 10 are prepared. The washable backsheet 15 is made of a 40 gsm breathable polymeric sheet sold by Swanson Plastics and has a width of 68 mm. The protective layer 55 is made of printable 0.6 osySMS sold by Kimberly-Clark. The backsheet 15 is bonded to the protective layer 55 by Easy Melt #34-5610 structural adhesive sold by National Starch. The adhesive 20 takes the form of Melt #34-5602 sold by National Starch and is applied to the adhesive surface 35 of the backsheet 15 . A release layer 25 made of a base paper of 45 gsm basis weight sold by Tekkote is bonded to the adhesive 20 on the bonding surface 35 . Each fragrance, Dandelion Breeze with Jasmine from Givaudan, Totally T from Givandan, Smoothing from Firmenich, Fresh Linen from Firmenich and Chamomile Dreams from Symrise, was applied to Patch 10 on. Each resulting patch 10 is applied to a garment after removing the relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com