Method of printing decoration in mould

A printing method and in-mold decoration technology, applied in coating and other directions, can solve problems such as poor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above-mentioned purpose, features and advantages of the present invention more comprehensible, preferred embodiments will be described in detail below together with the accompanying drawings.

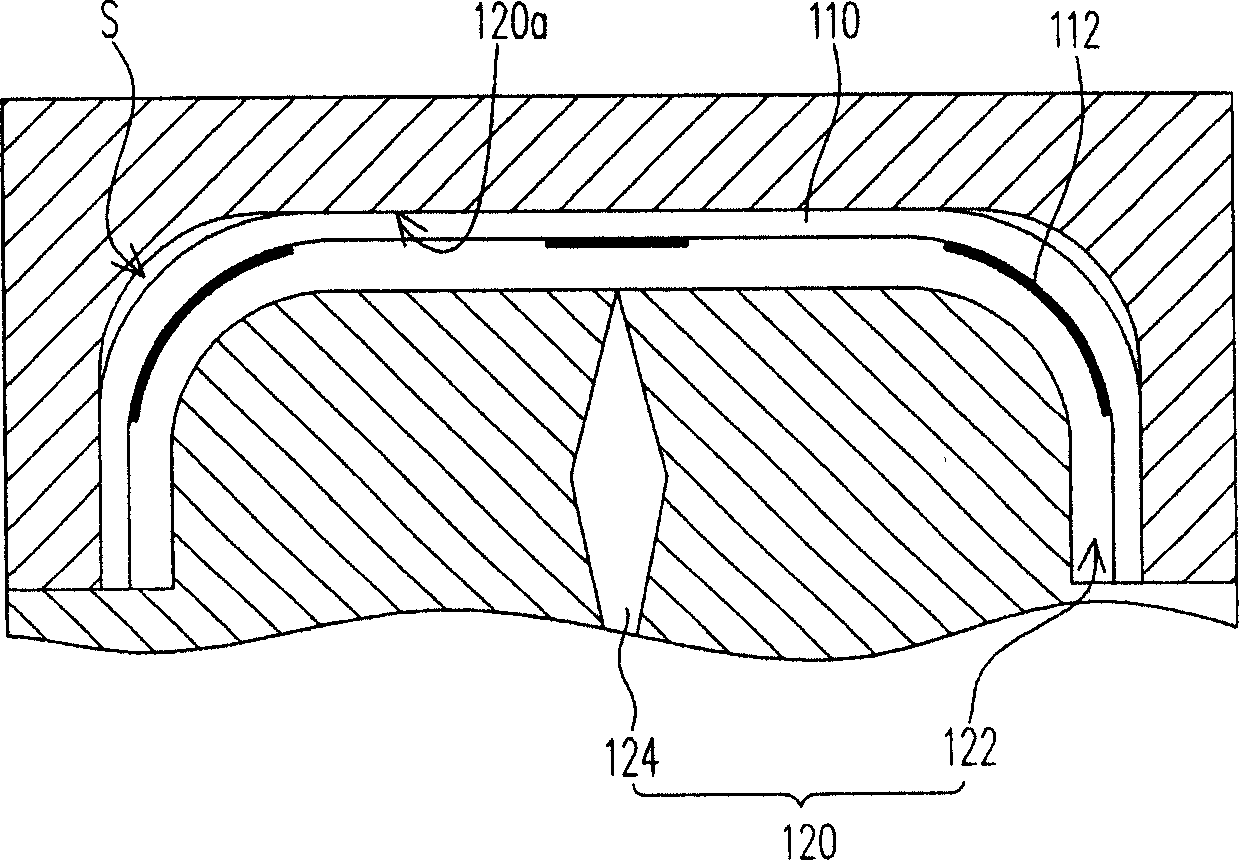

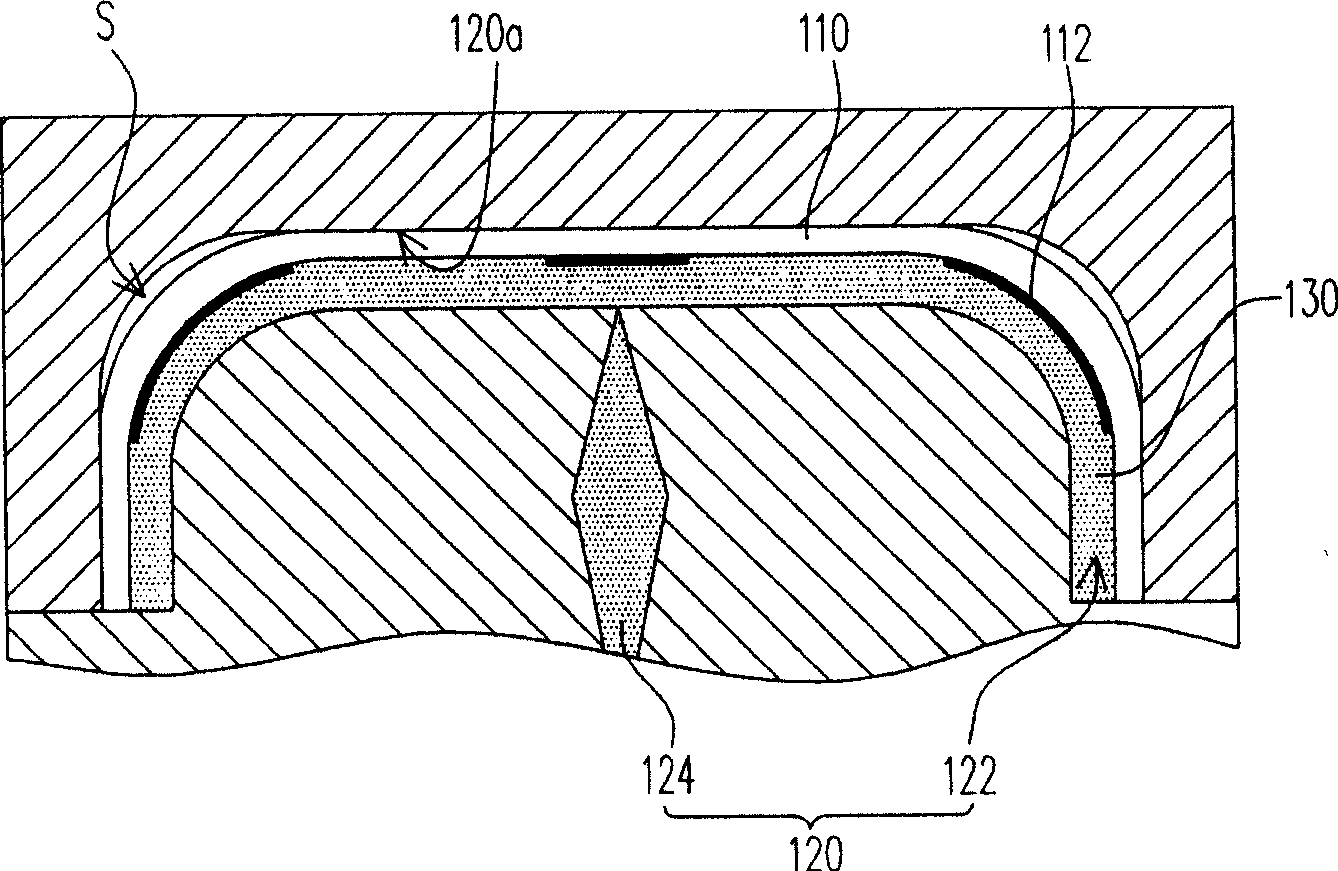

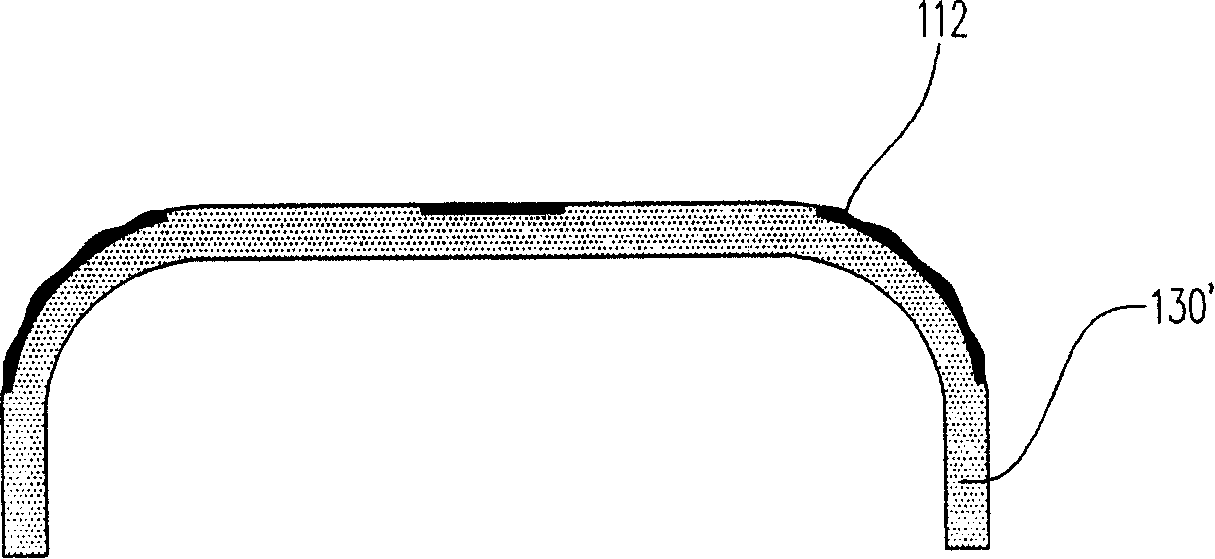

[0017] figure 2 It is a flow chart of an in-mold decoration printing method in a preferred embodiment of the present invention. Please refer to figure 2 , The in-mold decoration printing method of this embodiment includes the following steps. First, step S1 is performed to provide a patterned film and a mold, wherein the patterned film has a preset pattern, and the mold has a mold cavity, a plurality of air inlets, and a sprue, wherein the air inlet and the sprue communicate with the mold cavity, and The patterned film is arranged on the inner wall of the mould.

[0018] Next, step S2 is performed to inject plastic into the mold cavity from the pouring port. Afterwards, step S3 is performed, introducing airflow from the air inlet, so that the plastic is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap