Chamber filter plate

A technology of filter plates and filter presses, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as deformation, and achieve the effect of uniform force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

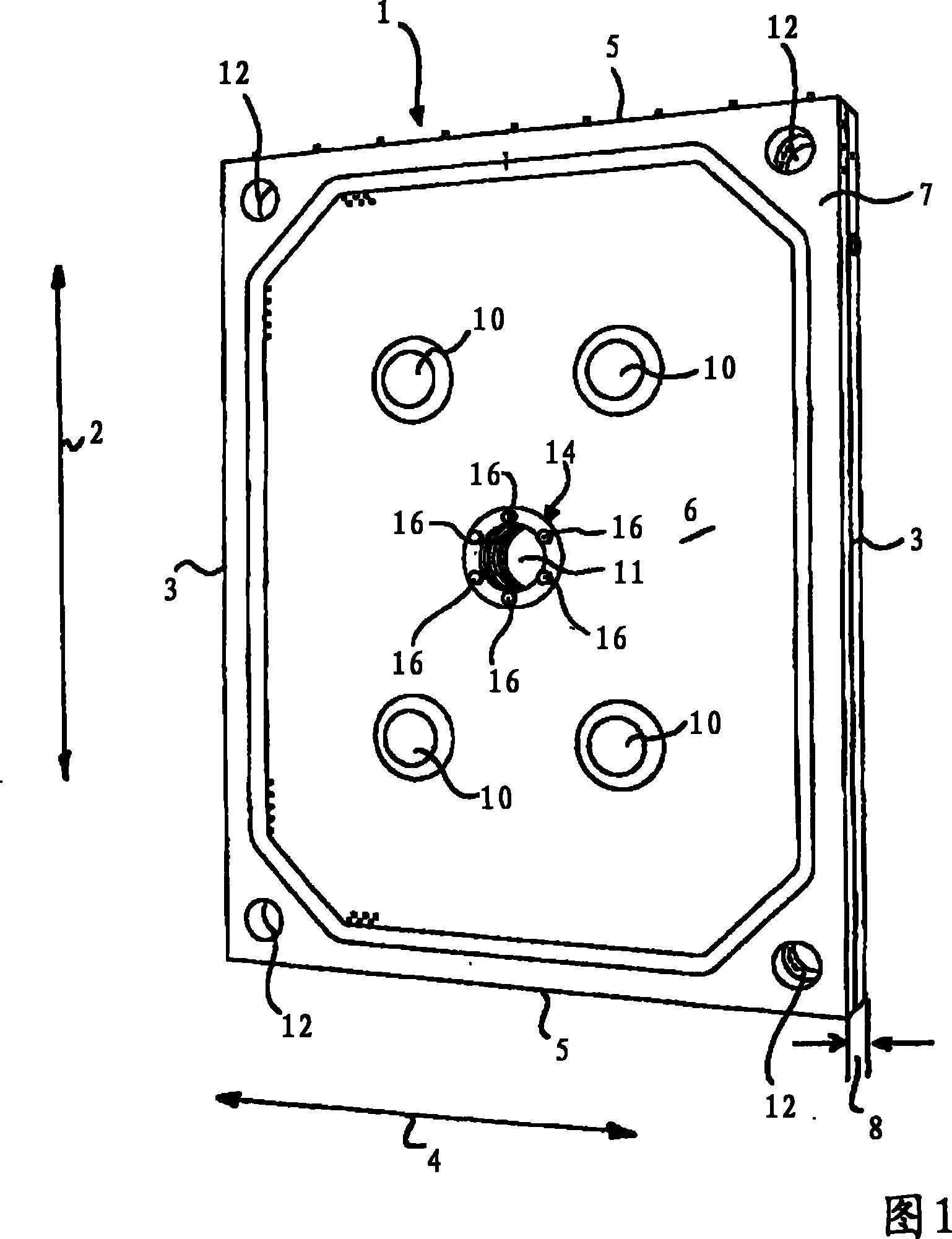

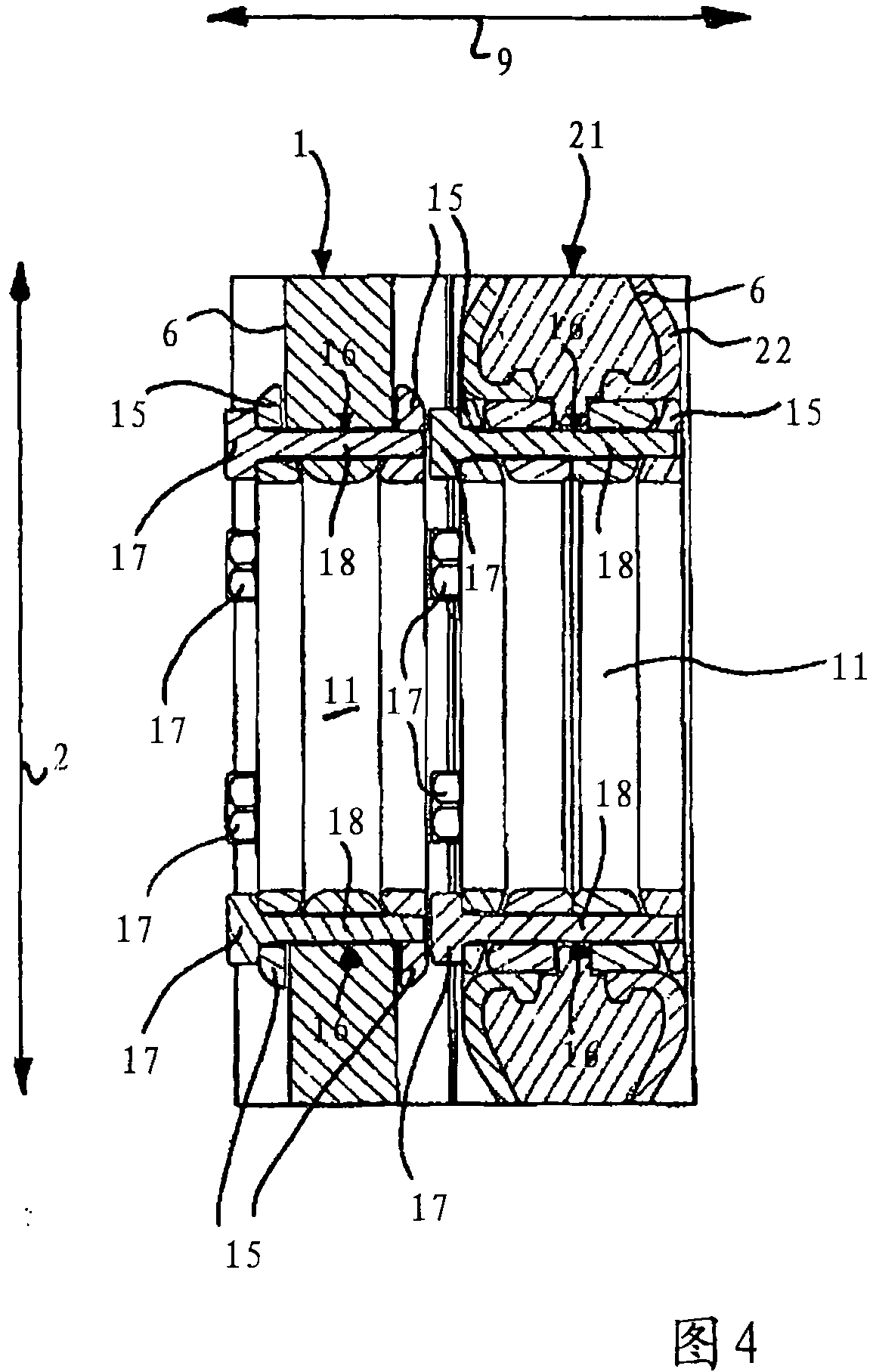

[0018] The rectangular box filter plate 1 has two longitudinal sides 3 running parallel in the longitudinal direction 2 and two likewise parallel transverse sides 5 running perpendicularly to the longitudinal sides 3 in the transverse direction 4 . The plate body of the chamber filter plate 1 is formed by a plate surface 6 and a plate edge 7 surrounding the plate surface 6 . The plate edge 7 extending around the plate surface 6 has a thickness 8 which is greater than the thickness of the plate body in the region of the plate surface 6 . This means that the plate surface 6 is set back relative to the plate edge 7 in the plate alignment direction 9 ( FIG. 3 ), which extends perpendicularly to the longitudinal direction 2 and the transverse direction 4 . In this way the plate edge 7 provides a filter tank which is open on one side, with the plate surface 6 as the filter tank bottom.

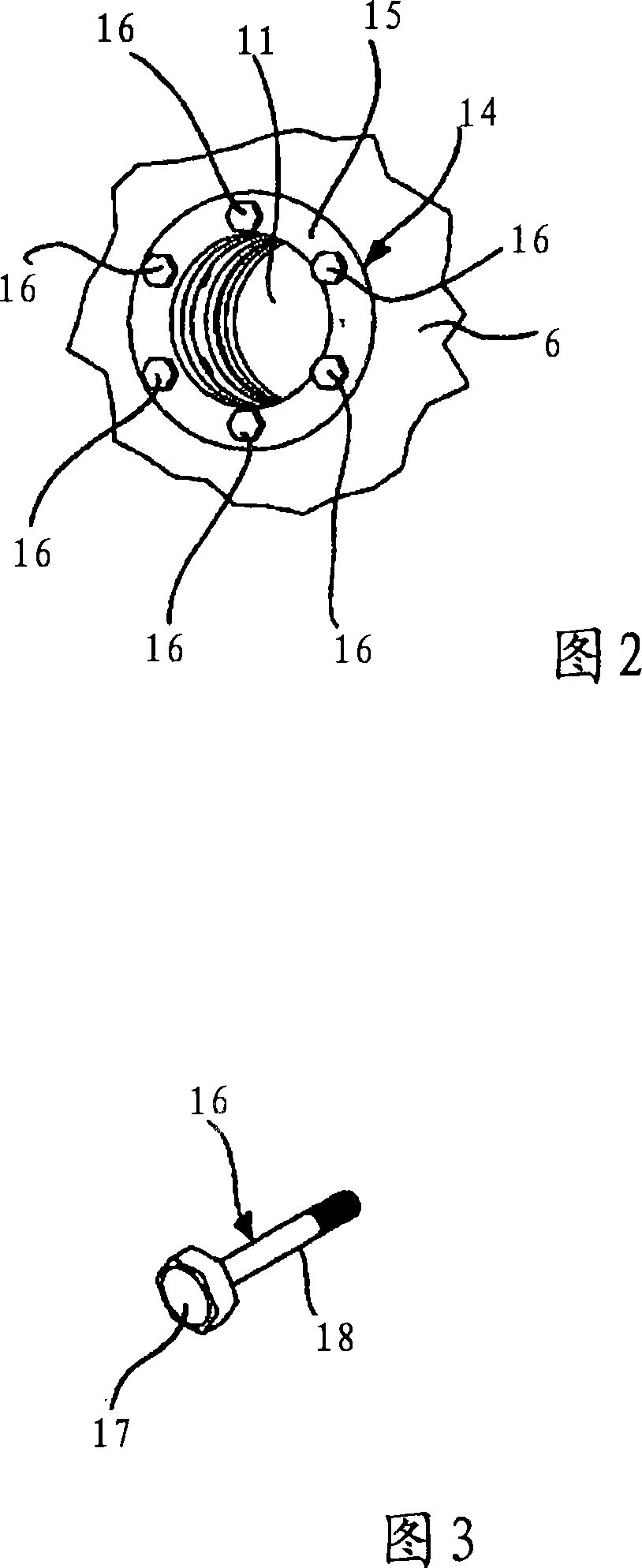

[0019] In the exemplary embodiment, four supports 10 protruding from the plate surface 6 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com