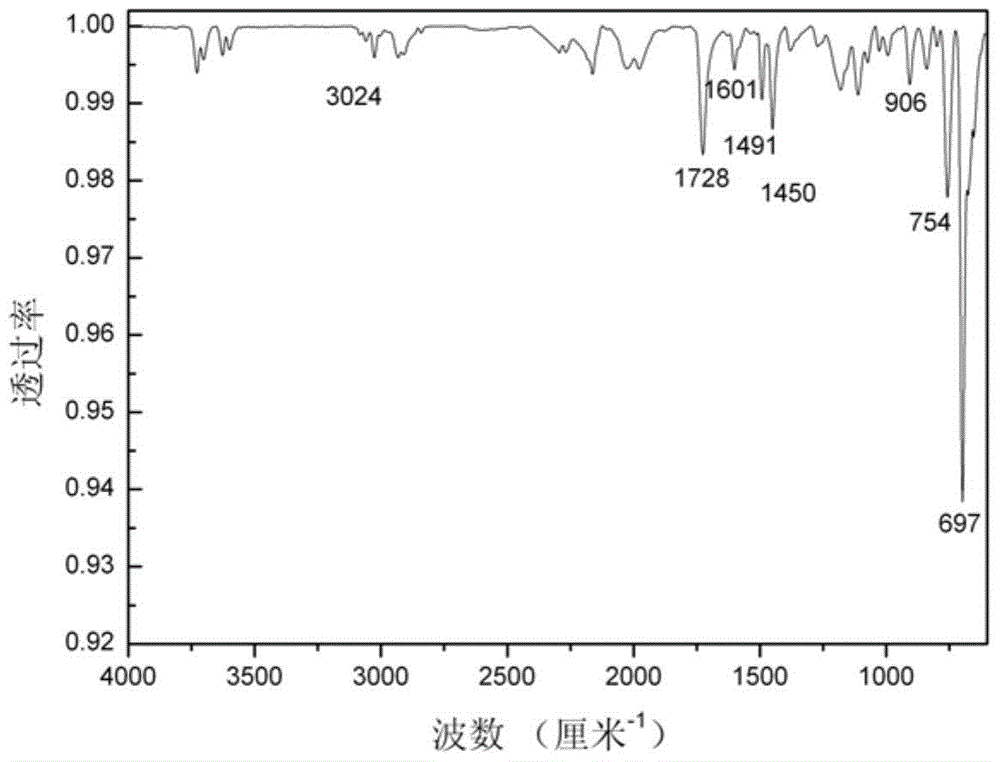

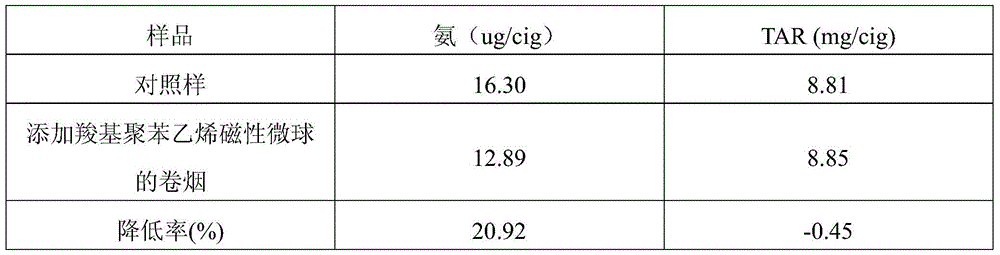

A carboxyl polystyrene magnetic microsphere composite material for reducing ammonia release in cigarette smoke and its preparation method and application

A technology of polystyrene and composite materials, applied in applications, chemical instruments and methods, tobacco, etc., can solve problems such as reducing ammonia release, and achieve the effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

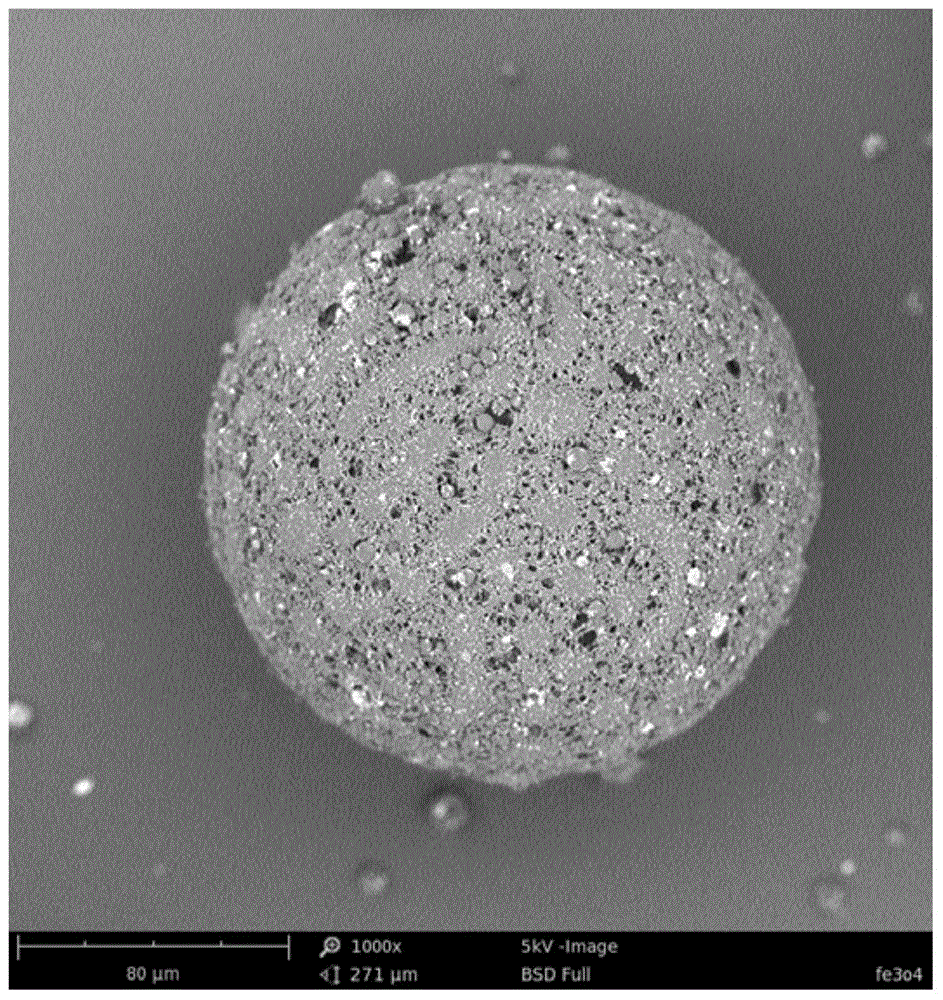

Embodiment 1

[0050] Nano Fe 3 o 4 Synthesis of the method: Weigh 139.01g of ferrous sulfate heptahydrate, dissolve 60.06g of urea in 500ml of deionized water, stir until completely dissolved to form a clear and transparent solution, then add 50ml of ethylene glycol to the system under stirring, mix well, and add The system is fed with high-purity nitrogen to drive away the dissolved oxygen in the solution. Then slowly raise the temperature, it can be seen that the color of the solution gradually changes from light green to turbid, and finally a dark green precipitate is formed, which is refluxed at 90°C for 1 hour. At this time, 30% hydrogen peroxide is added dropwise to the system several times until the dark green precipitate is completely transformed into a black precipitate. Reflux was then continued for an additional 3 hours. The reacted system was cooled to room temperature, then washed with deionized water until neutral, then transferred to a beaker filled with deionized water and...

Embodiment 2

[0061] Nano Fe 3 o 4 Synthesis of: take 13.90g of ferrous sulfate heptahydrate and dissolve it in 250ml of deionized water, feed high-purity nitrogen into the system to drive away the dissolved oxygen in the solution, then add 100ml of aqueous solution containing 28g of hexamethylenetetramine, the solution It immediately turned dark green, then added 2g of polyethylene glycol 200 to it, stirred for half an hour and then slowly raised the temperature, it can be seen that the color of the solution gradually became turbid and finally formed a dark green precipitate, refluxed at 85°C for 1.5 hours, and then distributed to the system The sodium hypochlorite aqueous solution was added dropwise several times until the dark green precipitate was completely transformed into a black precipitate, and then reflux was continued for 4 hours. Cool to room temperature, then filter and wash with deionized water until neutral, transfer to a beaker filled with deionized water, seal and store fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com