One-dimensional nitrogen-doped carbon vesicle, battery positive electrode material and synthesis method thereof

A nitrogen-doped carbon, synthesis method technology, applied in battery electrodes, hybrid capacitor electrodes, nanotechnology for materials and surface science, etc., can solve the problems of complex synthesis methods, low synthesis yields, etc. The effect of high nitrogen content and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In Example 1, the synthesis method of one-dimensional nitrogen-doped carbon vesicles adopts the following steps:

[0034] Grind and mix 0.2g cyanamide and 1g mesoporous silica template;

[0035] Put the ground and mixed powder into N 2 In a tubular furnace with atmosphere, heat up to 800°C at 5°C / min for 2 hours;

[0036] After completion, cool down to room temperature and take it out, and use 1M NaOH to stir at 80°C for 12 hours to remove the mesoporous silica template to obtain one-dimensional nitrogen-doped carbon vesicles.

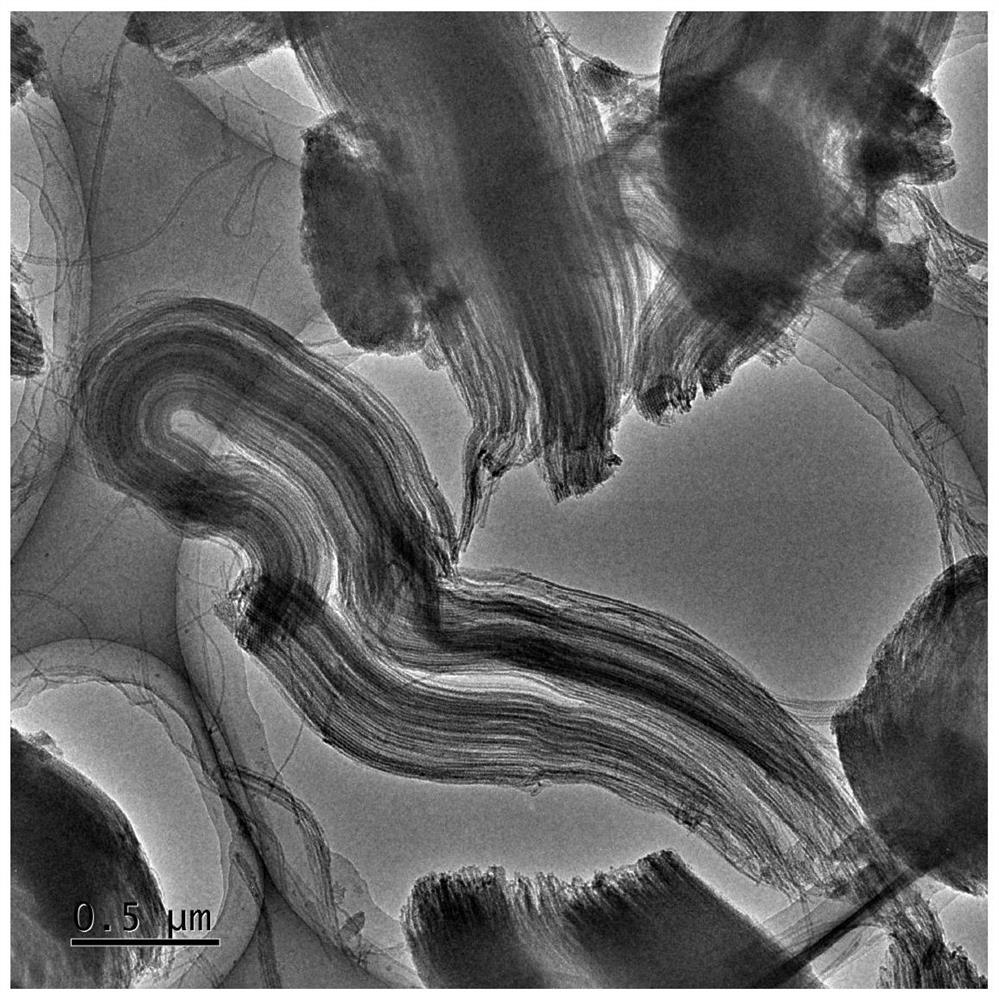

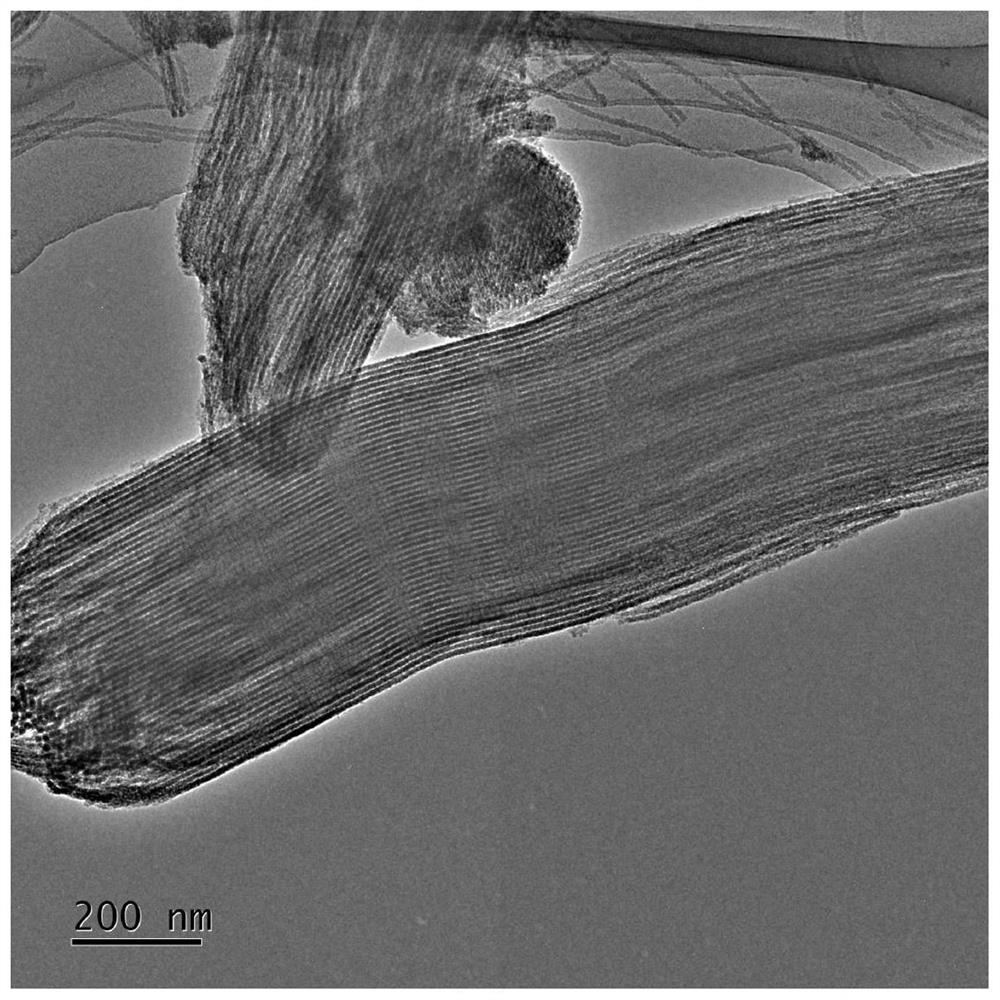

[0037] figure 1 A transmission electron microscope image at a resolution of 0.5 μm of the mesoporous silica template used in the one-dimensional nitrogen-doped carbon vesicle of Example 1 is shown. figure 2 The transmission electron microscope image of the mesoporous silica template used in the one-dimensional nitrogen-doped carbon vesicle of Example 1 at a resolution of 200 nm is shown.

[0038] like figure 1 and figure 2 As shown, the ...

Embodiment 2

[0041] In Example 2, the synthesis method of one-dimensional nitrogen-doped carbon vesicles adopts the following steps:

[0042] Grind and mix 0.2g dicyandiamide and 1g mesoporous silica template;

[0043] Put the ground and mixed powder into H 2 In a tube furnace with atmosphere, heat up to 700°C at 5°C / min for 6 hours;

[0044] After completion, cool down to room temperature and take it out, and use 1M NaOH to stir at 80°C for 12 hours to remove the mesoporous silica template to obtain one-dimensional nitrogen-doped carbon vesicles.

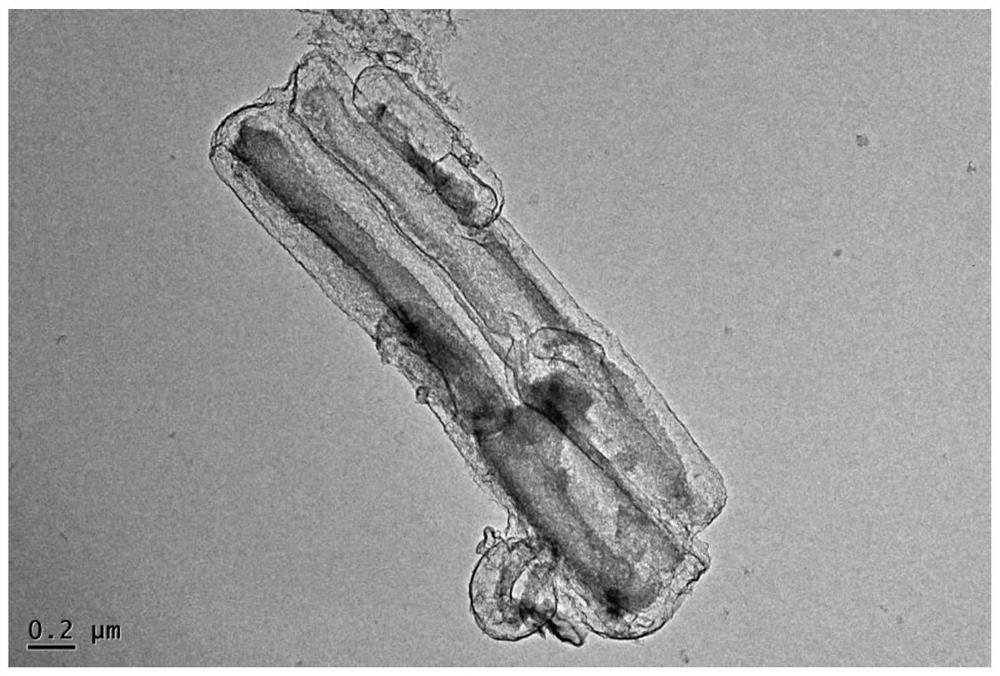

[0045] Figure 4 It is a transmission electron microscope image of the one-dimensional nitrogen-doped carbon vesicle of Example 2 at a resolution of 0.5 μm.

[0046] like Figure 4 As shown, the mesoporous silica template used in Example 2 is a one-dimensional mesoporous nanorod, and the obtained one-dimensional nitrogen-doped carbon vesicle has a hollow core-shell structure inside, and the core-shell structure is rod-shaped , In addition,...

Embodiment 3

[0052] In Example 3, the synthesis method of one-dimensional nitrogen-doped carbon vesicles adopts the following steps:

[0053] Grind and mix 0.2g cyanamide and 1g mesoporous silica template;

[0054] Put the ground and mixed powder into H 2 -In a tube furnace with an Ar atmosphere, heat up to 700°C at 10°C / min and hold for 2 hours;

[0055] After completion, cool down to room temperature and take it out, and use 1M NaOH to stir at 80°C for 12 hours to remove the mesoporous silica template to obtain one-dimensional nitrogen-doped carbon vesicles.

[0056] The one-dimensional nitrogen-doped carbon vesicle of Example 3 has a hollow core-shell structure inside, the core-shell structure is rod-shaped, and its nitrogen content is 5.6wt%, and the specific surface area of the core-shell structure is 246 cm 3 / g.

[0057] The one-dimensional nitrogen-doped carbon vesicles of Example 3 are used as the sulfur-loaded positive electrode material for lithium-sulfur batteries, that is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com