A kind of spherical s/c@moo2 composite material and its preparation method and application

A composite material and spherical technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of limited energy density and unsatisfactory technological development, and achieve the effect of simple equipment requirements, simple and feasible methods, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. Preparation process:

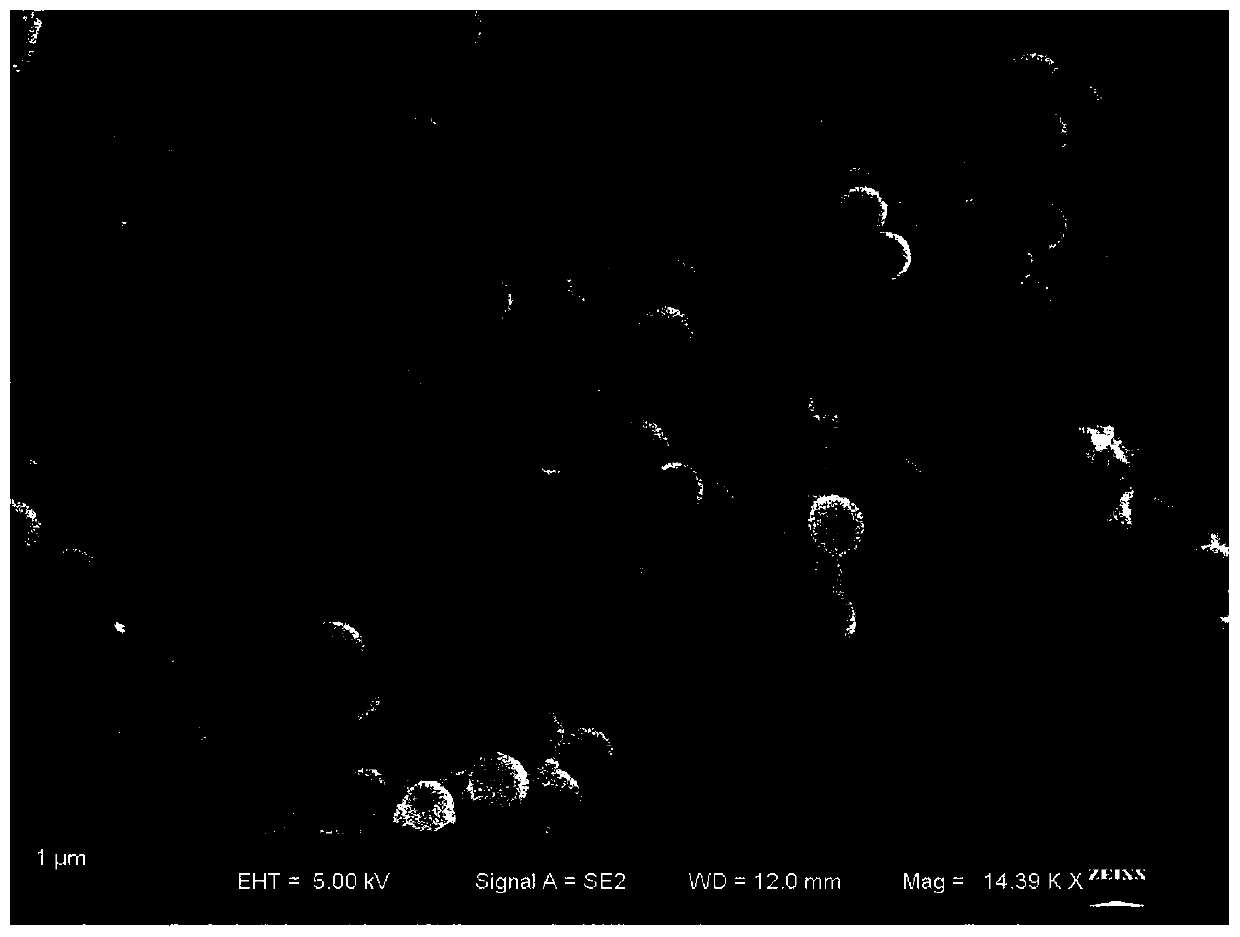

[0027] 1) Preparation of TBA 3 PMo 12 o 40 Composite material: 1.843g phosphomolybdic acid (H 3 Mo 12 o 40 P) and 0.996g tetrabutylammonium bromide (C 16 h 36 NBr) was dissolved in deionized water and reacted in a water bath for 0.5-1h under magnetic stirring. After the reaction, a yellow precipitate was obtained by suction filtration, and then vacuum-dried at 60°C to obtain 2.610g TBA 3 PMo 12 o 40 .

[0028] 2) Preparation of SiO 2 / C@TBA 3 PMo 12 o 40 Composite material: 20mgSiO 2 / C was added to 25mL toluene solution, magnetically stirred for 2h, and left to stand for 30min to obtain SiO 2 / C and toluene mixed solution. 20mg TBA 3 PMo 12 o 40 Dissolve in 25mL acetonitrile solution, then add this mixed solution to SiO 2 / C and toluene mixed solution, filtered and dried to obtain 36mgSiO 2 / C@TBA 3 PMo 12 o 40 composite material.

[0029] 3) Preparation of SiO 2 / C@MoO 2 Composite material: 36mgSiO 2 / C@TBA 3 PMo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com