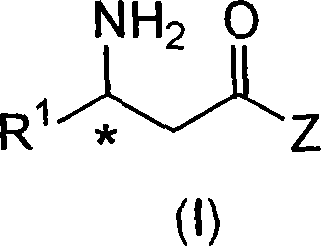

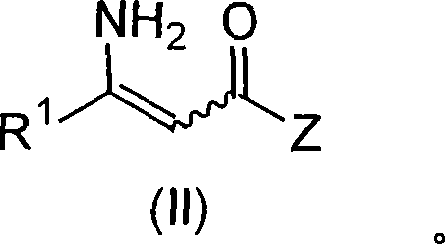

Process to chiral beta amino acid derivatives by asymmetric hydrogenation

A technology of compounds and alkyl groups, applied in the field of preparing chiral beta amino acid derivatives by asymmetric hydrogenation, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095]

[0096] (2R)-4-oxo-4-[3-(trifluoromethyl)-5,6-dihydro[1,2,4]triazolo[4,3-α]pyrazine-7(8H )- Base]-1-(2,4,5-trifluorophenyl)butan-2-amine (2-5)

[0097] 3-(Trifluoromethyl)-5,6,7,8-tetrahydro[1,2,4]triazolo[4,3-α]pyrazine, hydrochloride Preparation of (1-4)

[0098] Process 1

[0099]

[0100] Step A: Preparation of bishydrazide (1-1)

[0101] Hydrazine (20.1 g, 35% by weight in water, 0.22 mol) was mixed with 310 mL of acetonitrile. 31.5 g of ethyl trifluoroacetate (0.22 mol) were added over 60 min. The internal temperature increased from 25°C to 14°C. The resulting solution was aged at 22-25°C for 60 min. Cool the solution to 7°C. At a temperature below 16°C, 17.9 g of 50% by weight aqueous NaOH (0.22 mol) and 25.3 g of chloroacetyl chloride (0.22 mol) were added simultaneously over 130 min. When the reaction was complete, the mixture was vacuum distilled at 27-30°C and 26-27 Hg vacuum to remove water and ethanol. During the distillation, 720...

Embodiment 2

[0127] (2R)-4-oxo-4-[3-(trifluoromethyl)-5,6-dihydro[1,2,4]triazolo[4,3-α]pyrazine-7(8H )- Preparation of -1-(2,4,5-trifluorophenyl)butan-2-amine (2-5)

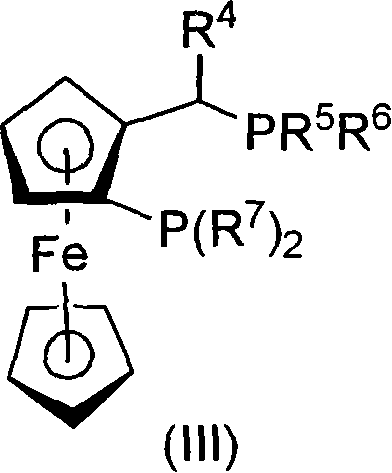

[0128] Under a nitrogen atmosphere, the chloro(1,5-cyclooctadiene) rhodium(I) dimer {[Rh(cod)Cl] 2} (0.074 mg, 0.15 μmol) and (R,S) tert-butyl Josiphos (0.179 mg, 0.033 μmol), ammonium formate (6.6 mg, 0.15 mmol) and ketoamide 2-3 (6.1 mg, 15 μmol) into a 1-mL reactor. Additional degassed MeOH (200 μL) was added and the mixture was stirred for 5 h at 55° C. in a pressure vessel under nitrogen. The mixture was hydrogenated under 250 psi hydrogen at 55°C for 20 h. The experimental yield was 91% and the optical purity was 95% ee as determined by HPLC.

[0129] The following high performance liquid chromatography (HPLC) conditions were used to determine the percent conversion of the product:

[0130] Column: Agilent Extend C18, 150mm×4.6mm

[0131] Eluent: Solvent A: 80 / 20% by volume Water / Methanol 10mM TRIS pH 9

[01...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap