Filter structure of vacuum cleaner

A technology of filters and vacuum cleaners, applied in the direction of suction filters, etc., can solve problems such as unhygienic, troublesome dust removal, etc., and achieve the effects of convenient removal, improved application effect, and enhanced user reputation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

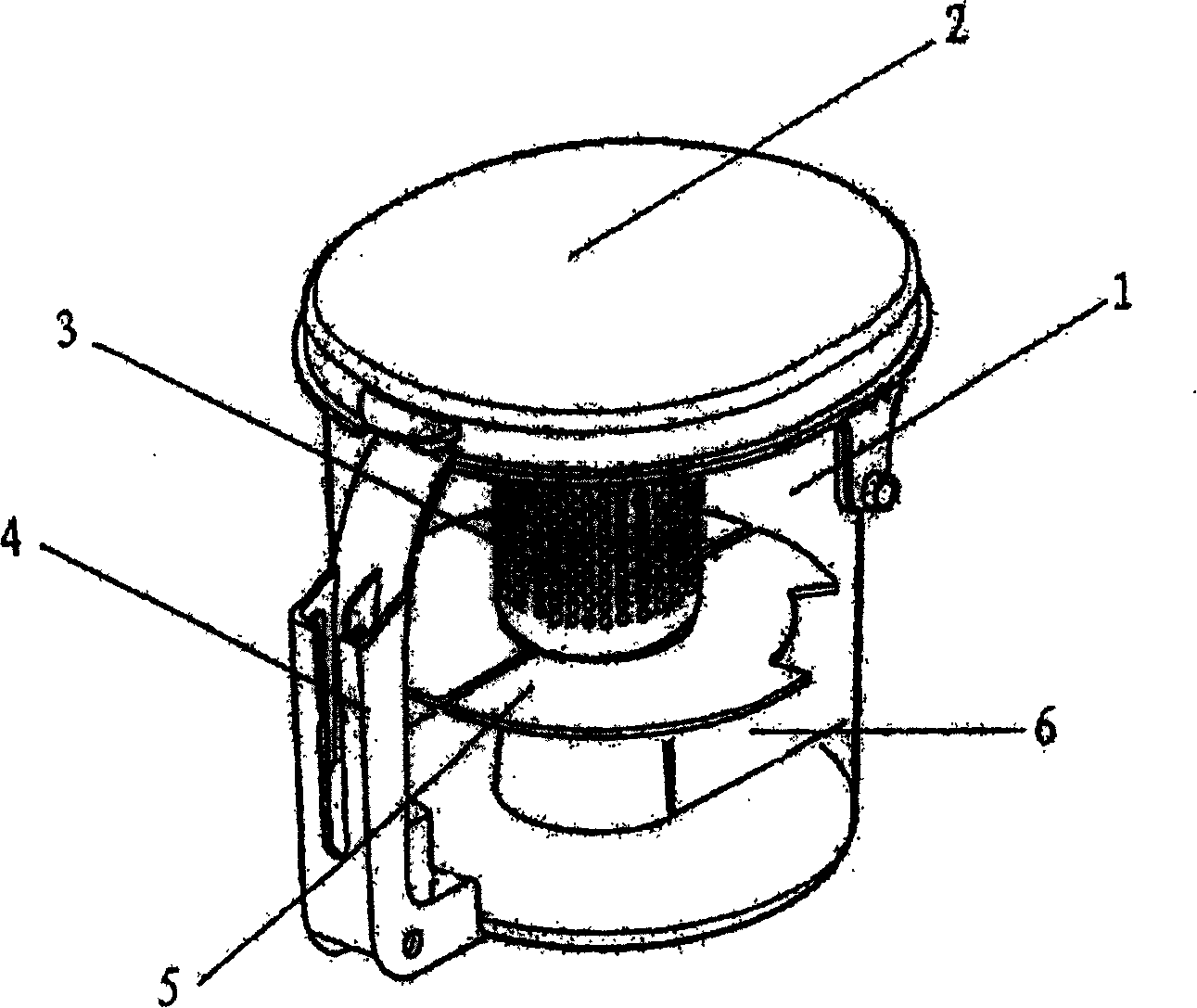

[0034] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

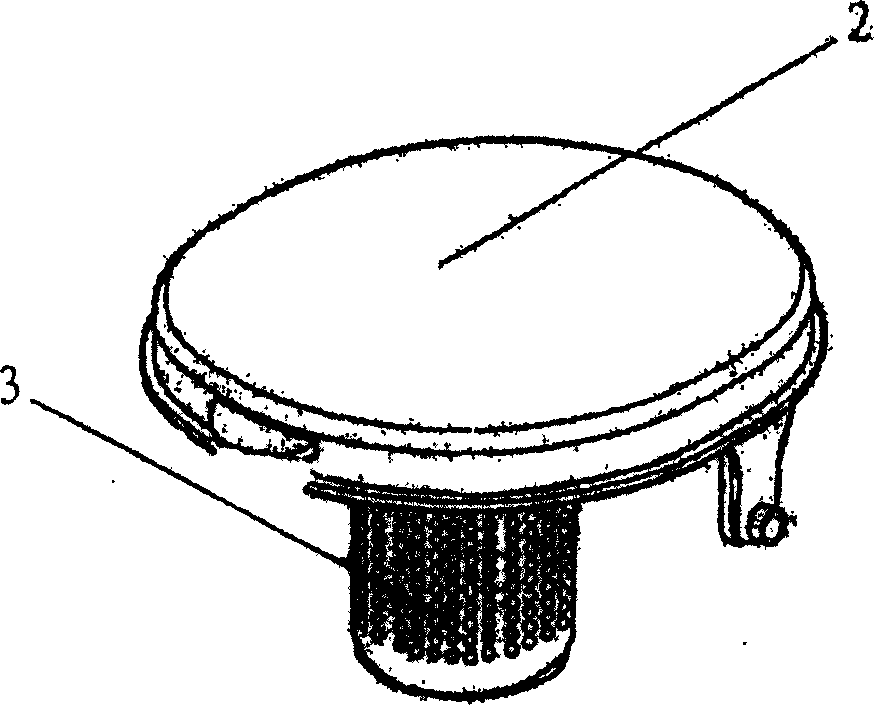

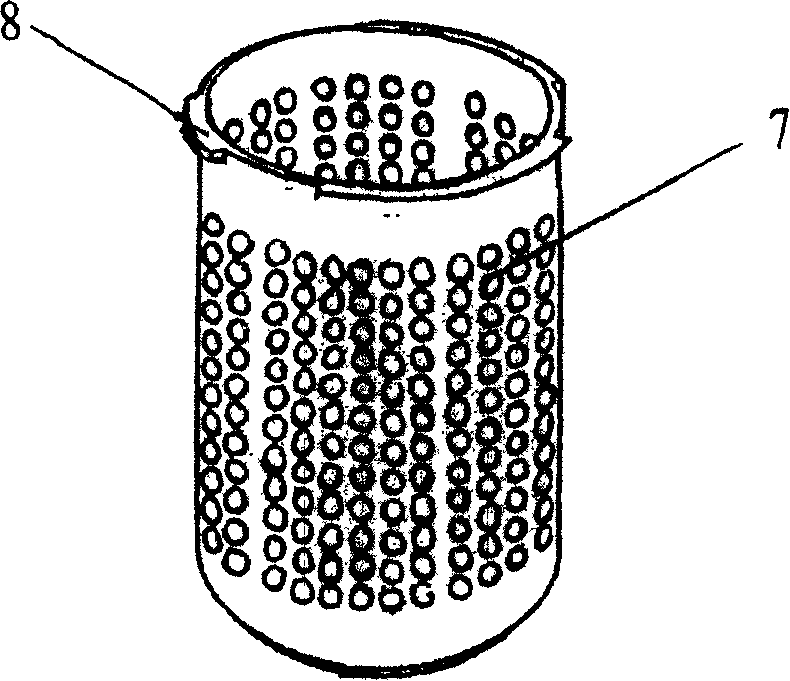

[0035] Figure 4 It is a schematic diagram of the filter involved in the present invention being fixed on the lid of the dust collecting barrel. Figure 5a It is a schematic diagram of the appearance of the filter in Fig. 3. Figure 5b It is a structural schematic diagram of the filter screen part of the filter in FIG. 3 . Figure 5c It is a structural schematic diagram of the filter element of the filter in Fig. 3 .

[0036] As shown in the figure, the vacuum cleaner filter structure of the present invention is composed of a filter core 90 provided with an opening mechanism on an end cover 91 and a filter screen 70 with an annular top end 71 , and the filter screen 70 is sleeved on the periphery of the filter core 90 . The filter core end cover 91 is connected together with the filter screen ring top 71 through an opening mechanism, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com