Roll wheel with wave grain and manufacturing method thereof

A manufacturing method and texture technology, applied in the field of rollers and their manufacturing, can solve the problems of monotonous shape and small variability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

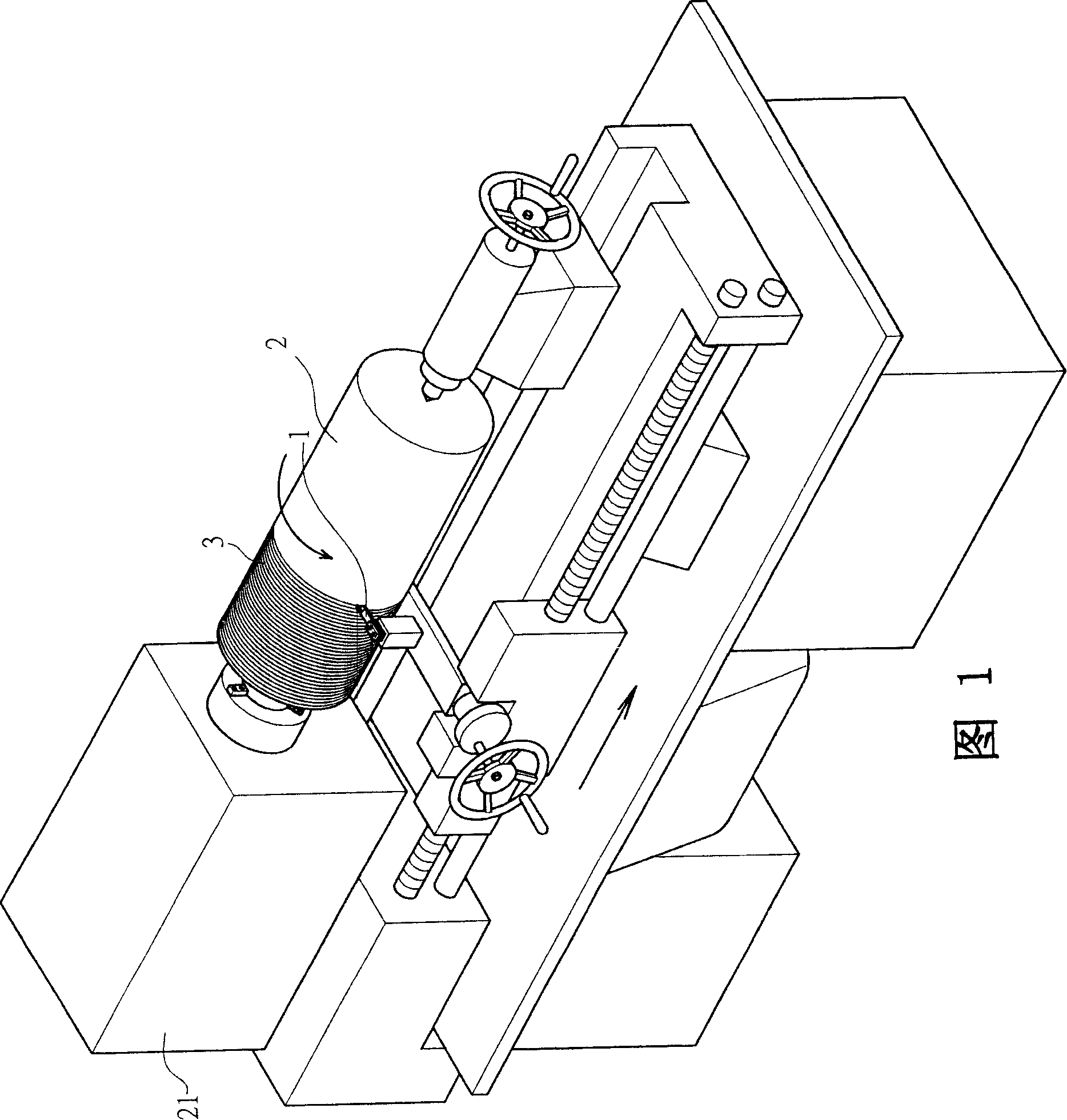

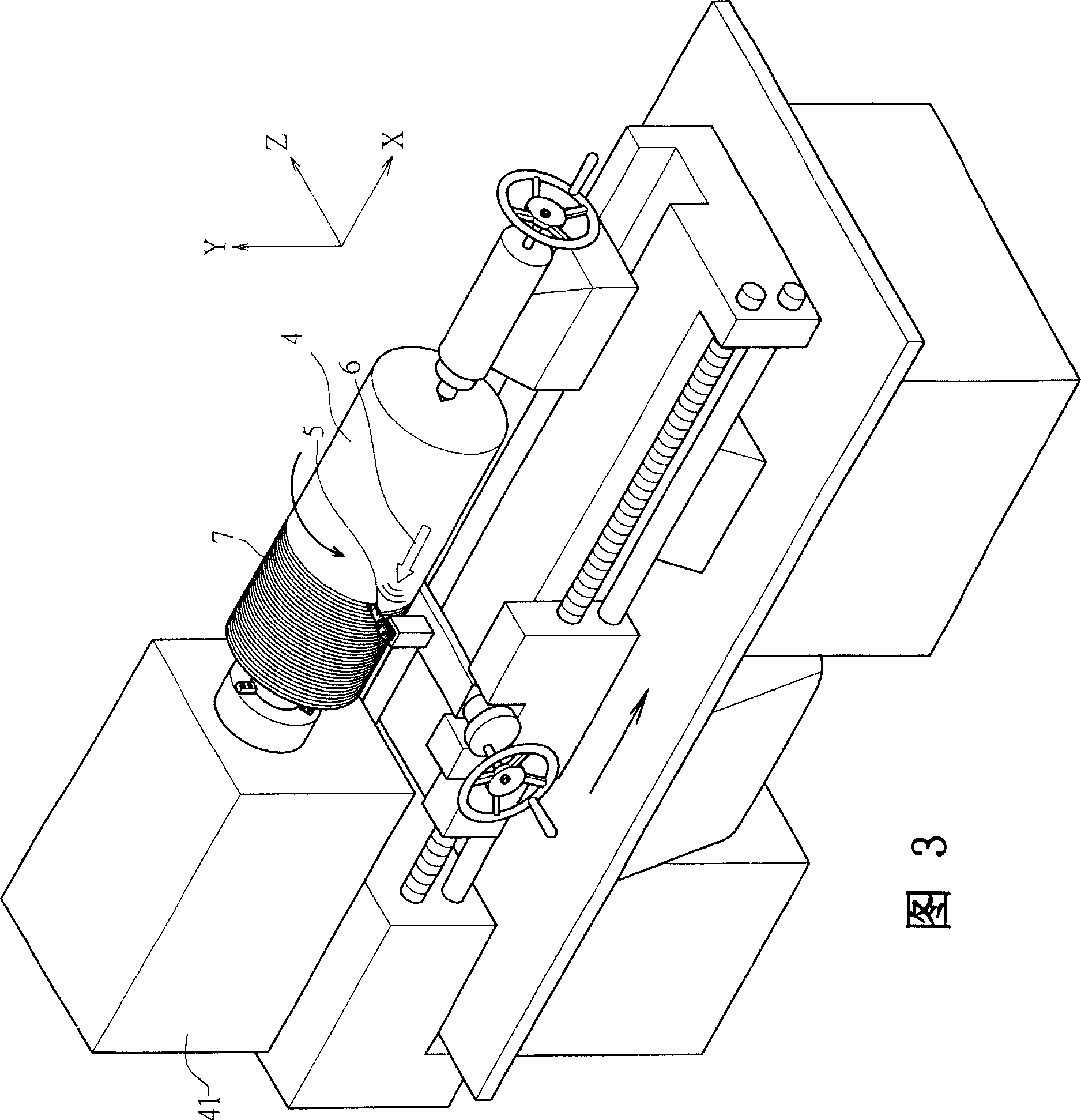

[0011] In order to further understand the structure of the present invention and the effects it produces, the accompanying drawings are specially described as follows:

[0012] At first, please refer to shown in Fig. 3, the present invention mainly is to set a cutting tool 5 on the side of roller 4, and this cutting tool 5 is provided with a vibration source 6, and this vibration source 6 can be an ultrasonic vibration source.

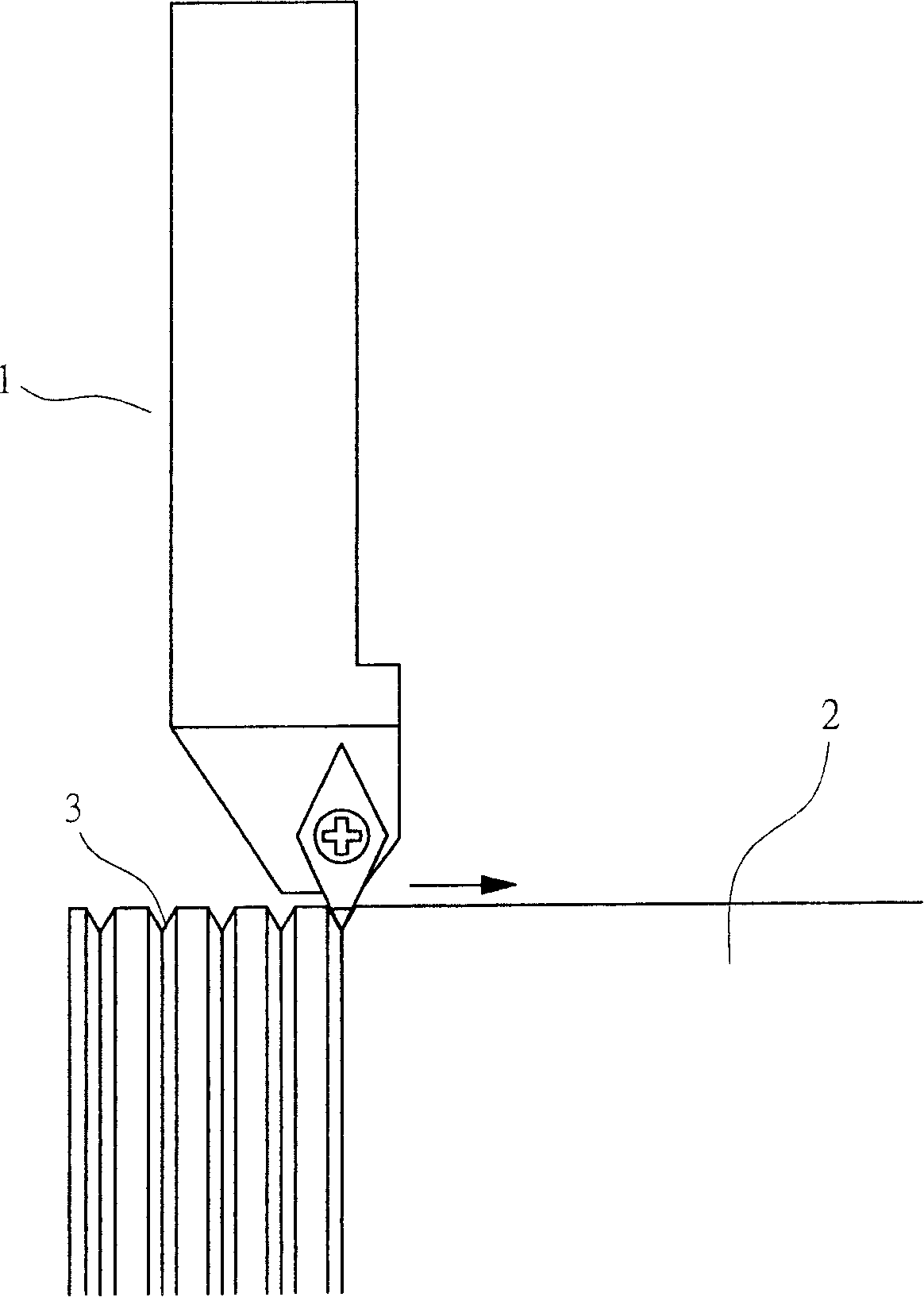

[0013] When the present invention is implemented, please refer to Figure 4 As shown, the tool 5 is placed close to the roller 4, and the vibration source 6 is arranged on one of the left and right sides of the tool 5 (that is, the X-axis direction). The roller 4 is connected with a power unit 41. When the power unit 41 is activated, it drives When the roller 4 rotates, the tool 5 is also activated to cut and move parallel to the roller 4 at the same time. During its movement, the vibration source 6 is opened in a timely manner to generate a slight vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com