Linear fibre high-speed perfume adding machine

A fiber and linear technology, applied in the field of special equipment, can solve problems such as poor centering effect, large deviation of fragrance rate, poor corrosion resistance of body materials, etc., and achieve stable fragrance rate, small loss of fragrance liquid and strong friction resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

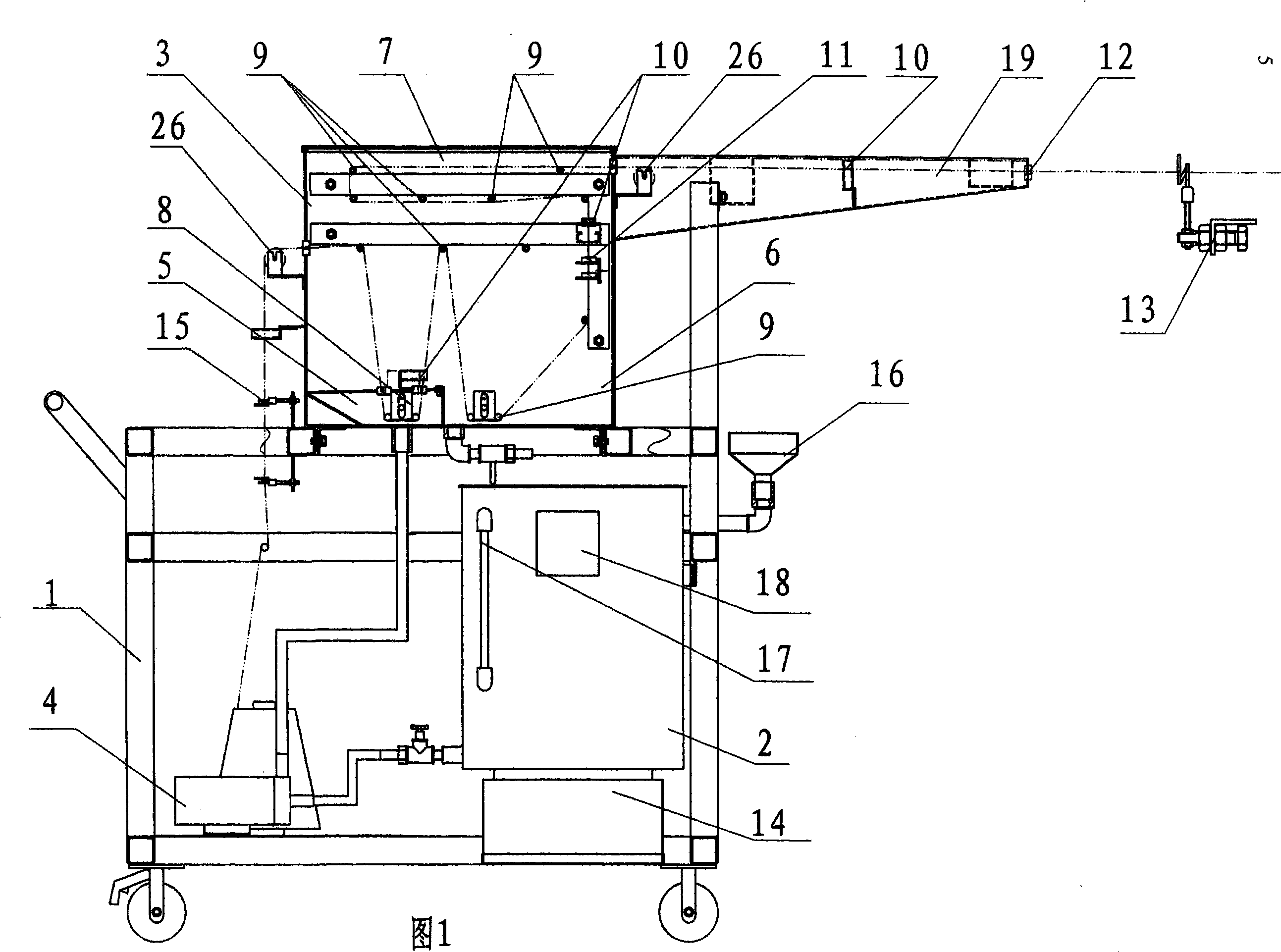

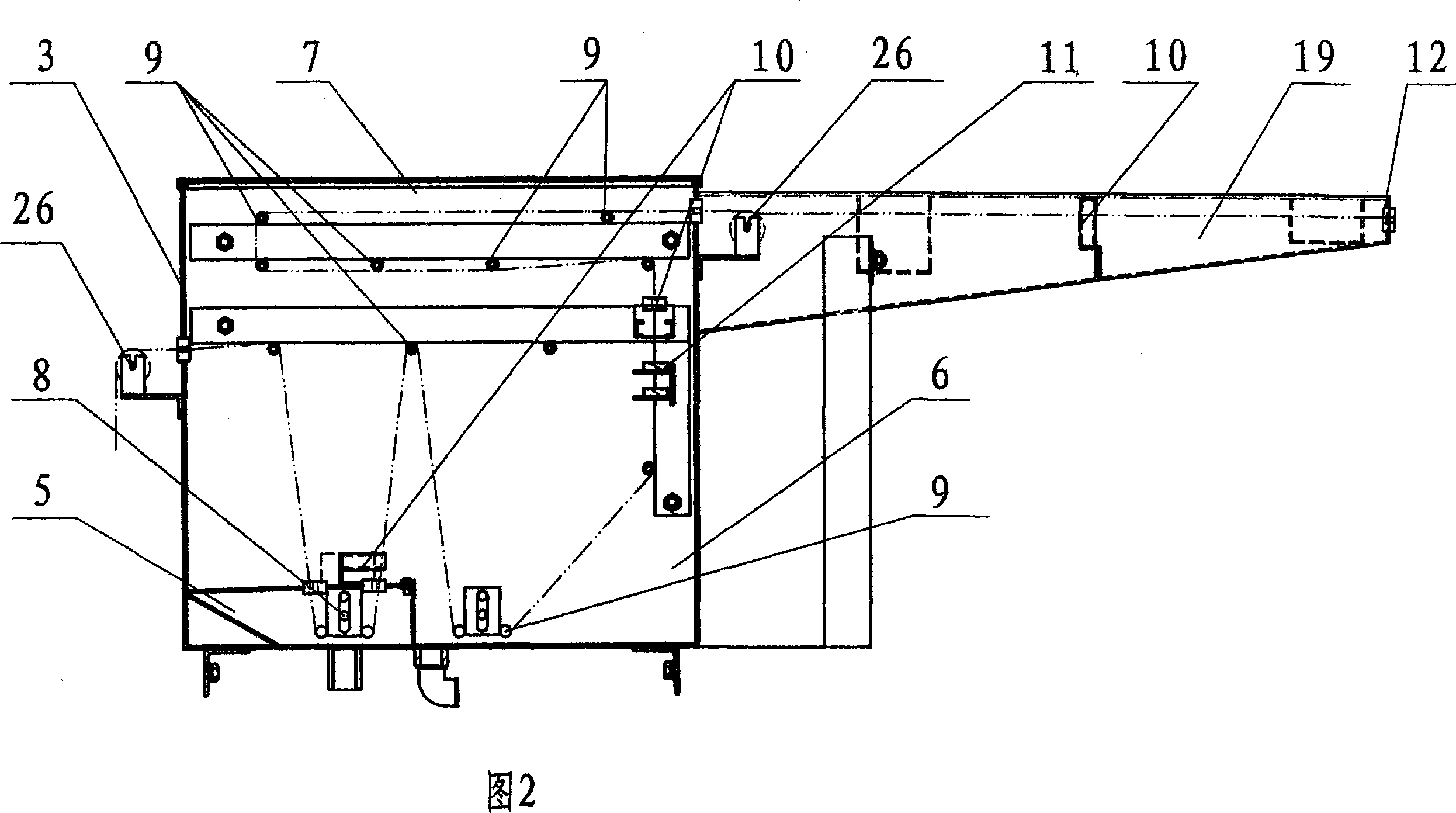

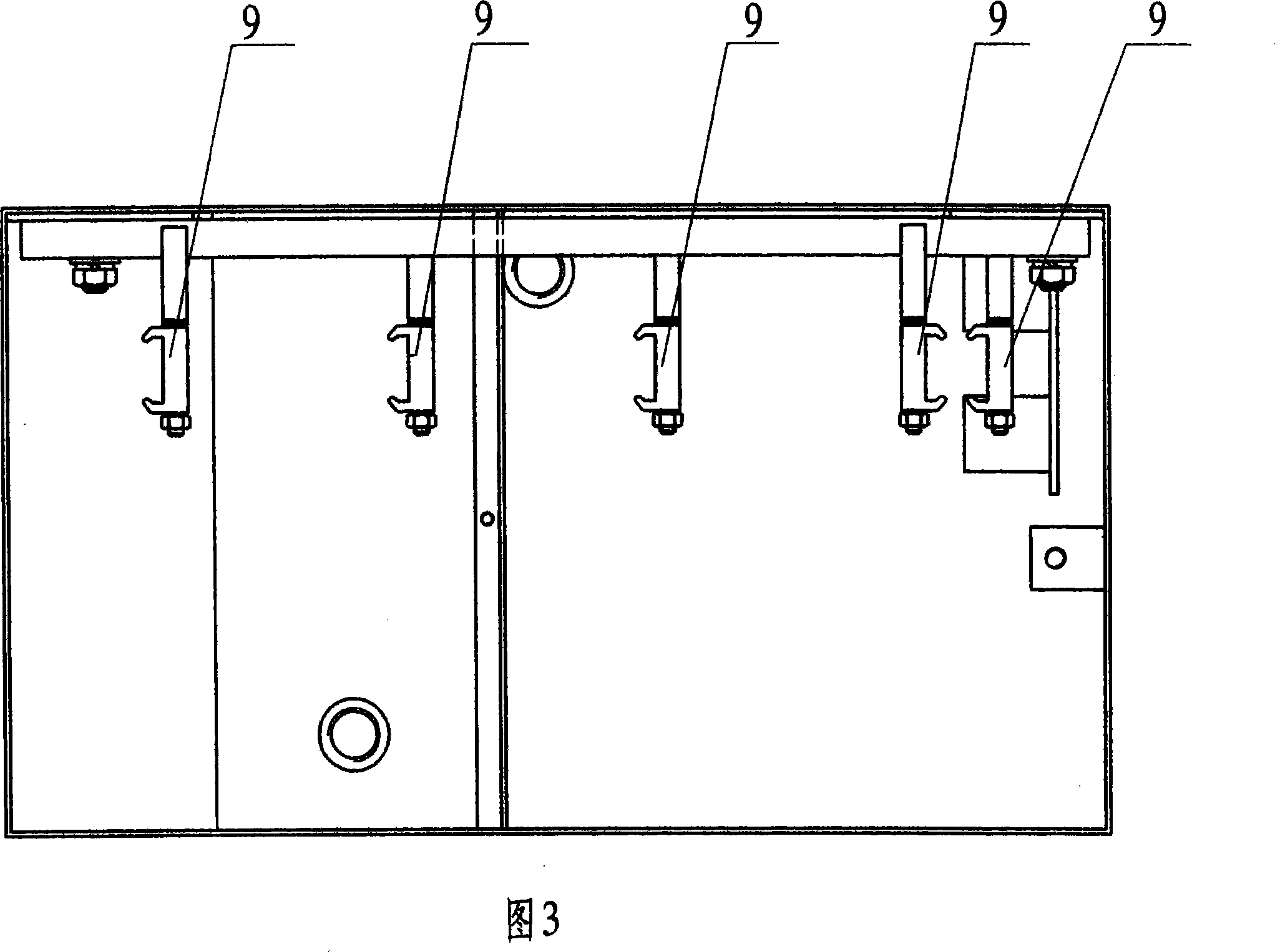

[0015] As shown in Figure 1, the linear fiber high-speed incense machine includes a main frame 1, on which a fragrance liquid storage 2 is arranged, on which the main frame 1 is also provided with a liquid filling pump 4, and the fragrance liquid storage 2 is connected with the liquid addition Pump 4 is connected. An upper incense trough 3 is arranged on the upper part of the main frame 1, and the outer wall of the upper incense trough 3 is provided with a guide wheel assembly 26. The upper incense trough 3 is roughly divided into three areas according to the upper, middle and lower sides, that is, the left side of the bottom is the upper incense. The infiltration area 5 and the middle part are the liquid removal and return area 6 and the upper tension adjustment area 7, and the liquid addition pump 4 is also connected with the incense infiltration area 5. The fragrance liquid in the fragrance liquid storage 2 can be sent in the fragrant infiltration zone 5 by liquid feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com