Thin film capable of enhancing brightness

A brightness and thin film technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of increasing the thickness of the backlight module and the manufacturing cost of components in the backlight module, and achieve the effect of reducing the manufacturing cost and quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

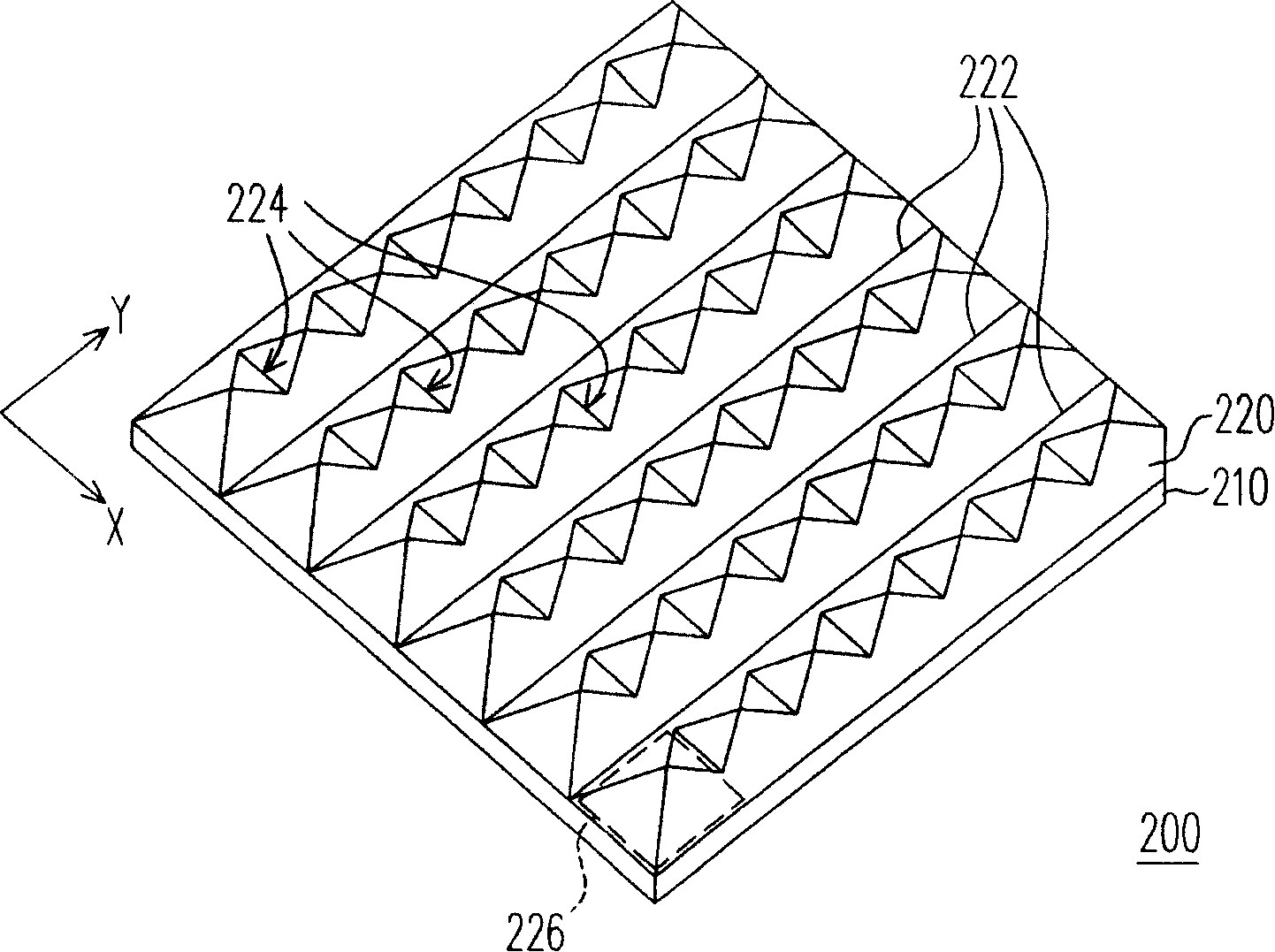

[0026] Figure 3A It is a three-dimensional schematic diagram of a film that can improve brightness according to an embodiment of the present invention; Figure 3B for along Figure 3A A schematic side view of a film that can improve brightness drawn in the X direction in ; Figure 3C for along Figure 3A Schematic side view of the brightness-enhancing film drawn in the Y direction in . Please also refer to Figure 3A , 3B And 3C, the brightness-enhancing film 200 mainly includes a substrate 210 and a brightness-enhancing structure 220 disposed on the substrate 210 . The surface of the brightness-enhancing structure 220 has a plurality of first grooves 222 arranged along the first direction (ie, the Y axis) and a plurality of second grooves 224 arranged along the second direction (ie, the X axis). The arrangement of the first grooves 222 and the second grooves 224 is perpendicular to each other, so as to define a plurality of bevel mirror units 226 arranged in an array. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com