Method for forecasting transient state temperature field with S type step length changing method in the process of plate belt hot rolling

A technology of transient temperature field and hot rolling process, applied in the field of rolling, can solve problems such as slow calculation speed, calculation time and calculation accuracy cannot be satisfied at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

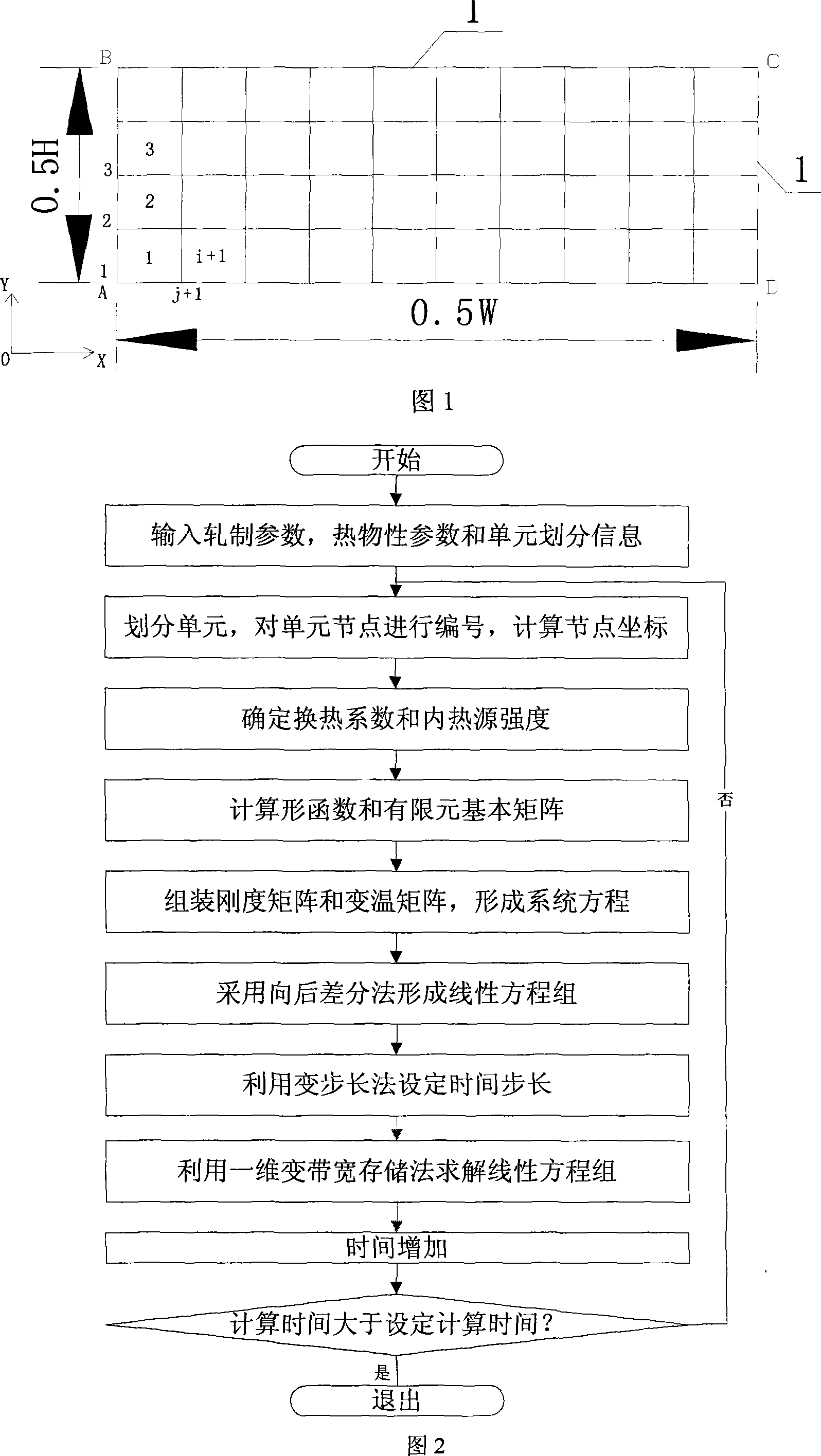

Method used

Image

Examples

Embodiment Construction

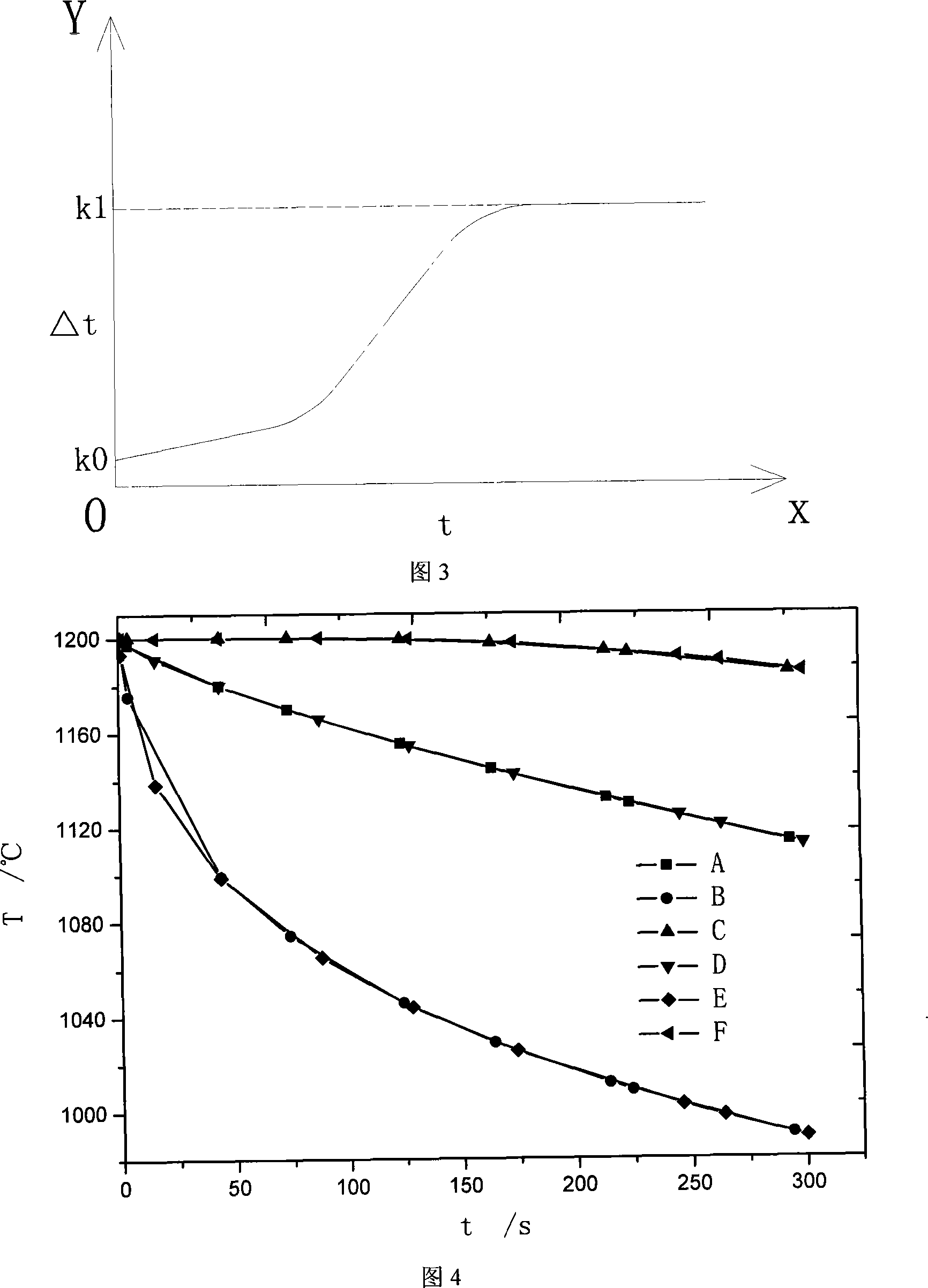

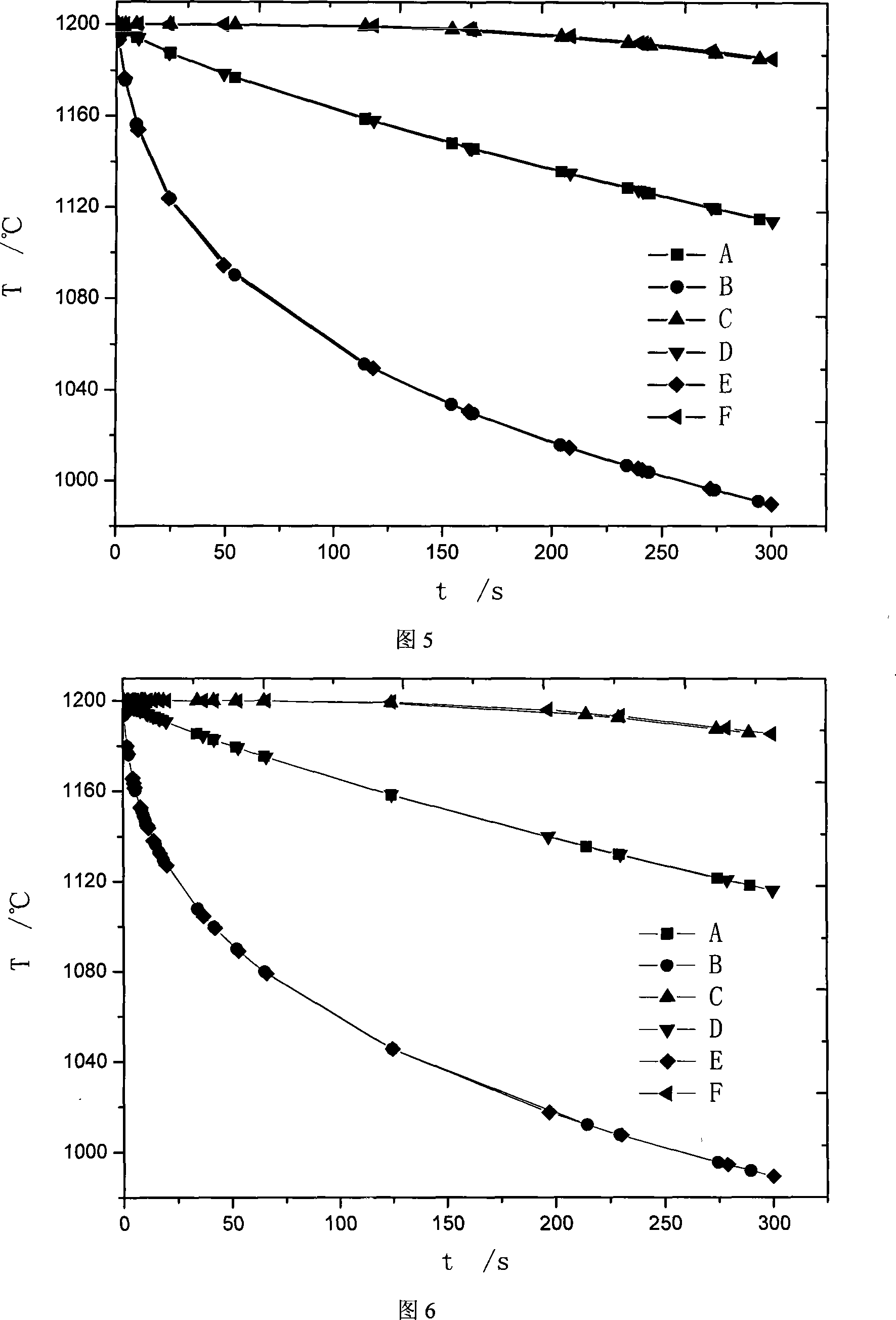

[0075] The temperature change of a hot-rolled slab from the furnace to the air-cooling process before dephosphorization is selected for prediction and analysis, and the effects of the fixed step method and variable step method on the calculation results and calculation time of the slab temperature are compared.

[0076] Example: Calculation conditions see Table 1

[0077] Table 1

[0078] Thermophysical parameters

[0079] Four groups of schemes are calculated and analyzed, and the unit division, fixed time step and variable step size of each scheme are as follows:

[0080] Plan 1 unit division: 20×10; fixed time step: Δt=1s; variable step setting: a=10.0, b=9.0, c=0.0001, d=2.5

[0081] Plan 2 unit division: 30×10, fixed time step Δt=1s; variable step setting: a=10.0, b=9.0, c=0.001, d=2.5

[0082] Plan 3 unit is divided into 40×20, fixed time step Δt=0.5s; variable step setting: a=15.0, b=14.5, c=0.0001, d=2.5

[0083] Plan 4 unit is divided into 50×20, fixed ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com