Method and arrangement for determination of the residual capacity of breathable air for an oxygen-generating breathing apparatus operated in circuit

A technology of circuit control and residual gas volume, which is applied in the direction of respiratory protection devices, life-saving equipment, fire rescue, etc., and can solve the problems that maintenance cannot be carried out immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

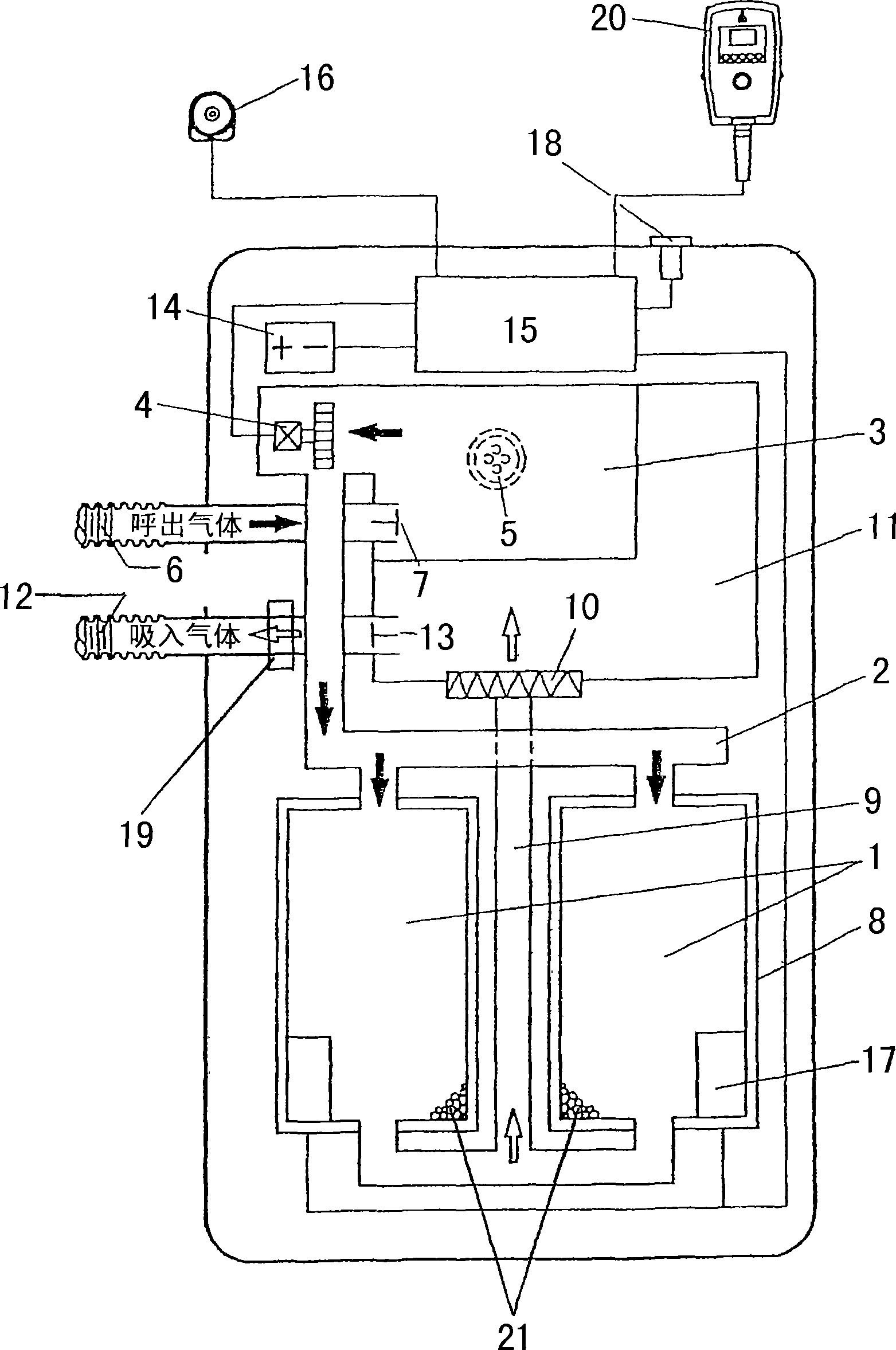

[0011] The respirator comprises two chemical tanks 1 arranged in parallel circuit, said chemical tanks being connected via a gas distributor 2 to an exhalation bag 3 equipped with a blower 4 . An excess valve 5 is integrally mounted on the wall of the exhalation bag 3 . An exhalation tube 6 with an exhalation valve 7 is connected to the exhalation bag 3 . Chemical tank 1 has a cooling jacket 8 and uses potassium superoxide (KO 2 ) particles 21 filled. A connecting pipe 9 connects the outlets of the two chemical tanks 1 with a suction bag 11 through a particle filter 10 . A suction tube 12 with a suction valve 13 is inserted into the suction bag 11 . The exhalation valve 7 and inhalation valve 13 are connected to a valve controller (not shown).

[0012] The exhaled gas rich in carbon dioxide flows into the exhalation bag 3 through the open exhalation valve 7 (while the inhalation valve 13 is closed) and is pressurized by the blower 4, and passes through the gas distributor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com