Roller-blind system with dampened final position

A cushioning device and rolling shutter technology, applied to windows, windshields, transportation and packaging, etc., can solve the problems of inappropriateness, impracticality, and inflexibility of rolling shutter components, and achieve the effect of simple design and simple mechanical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

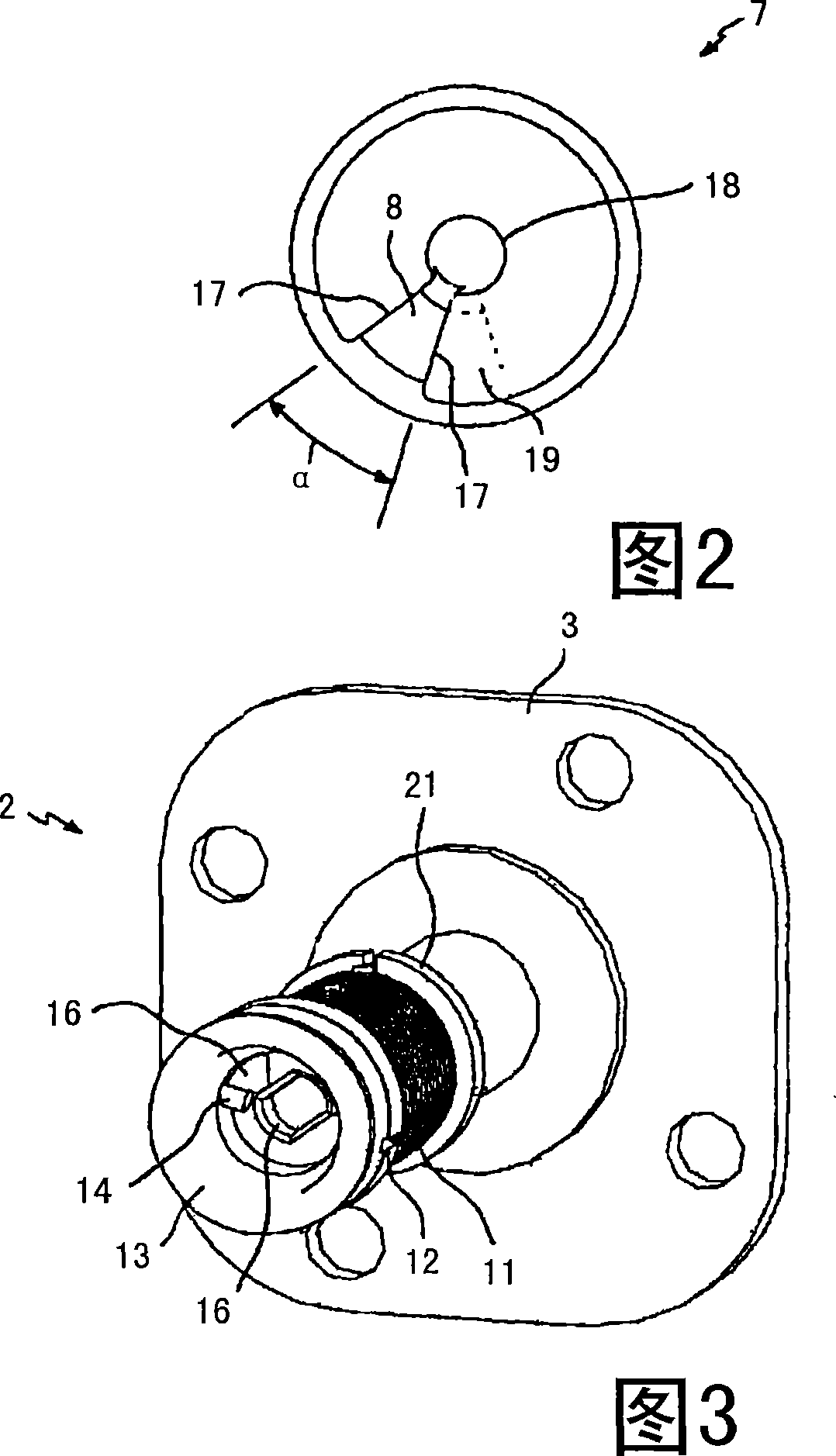

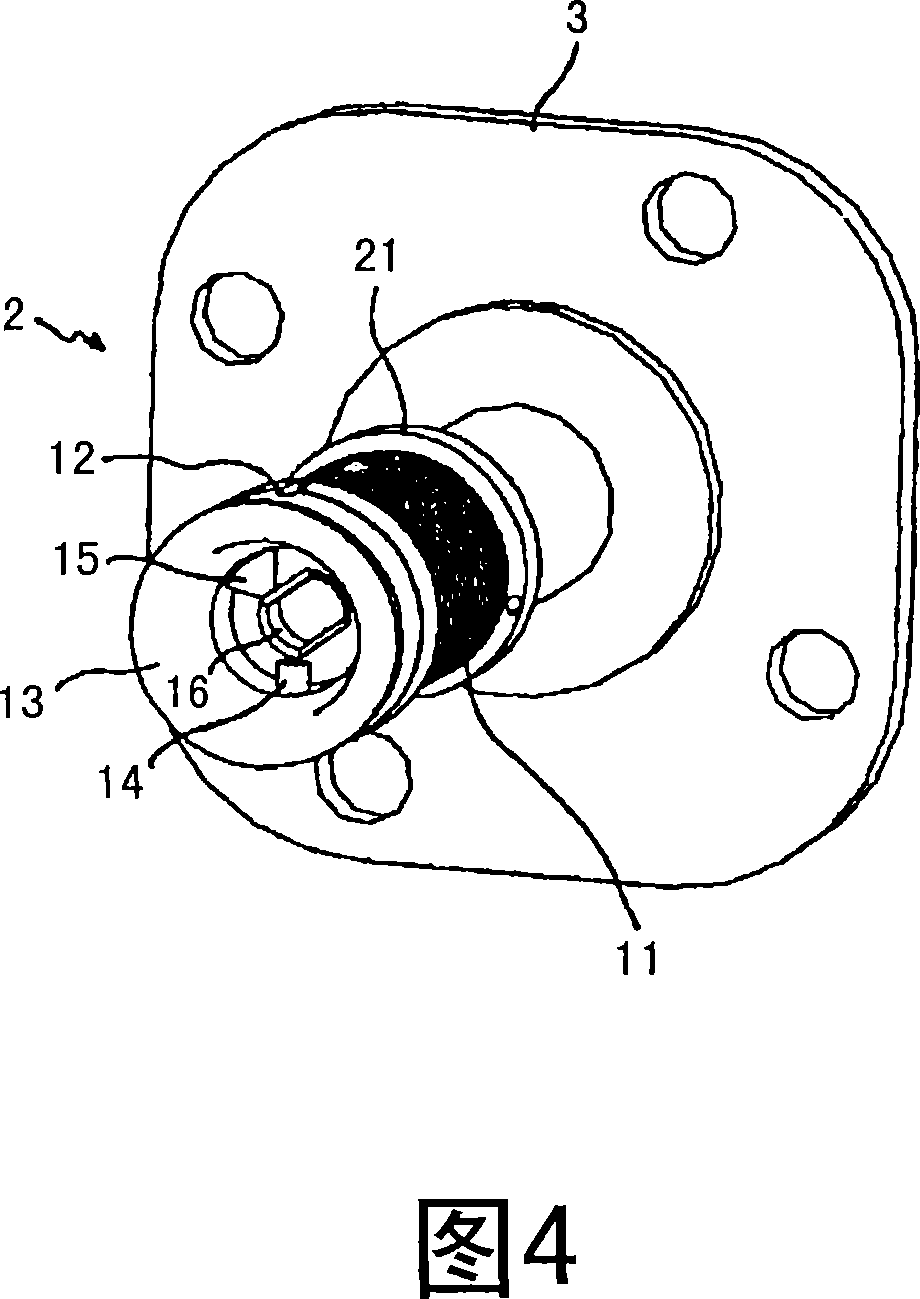

[0025] Like features in the figures are indicated by like reference numerals.

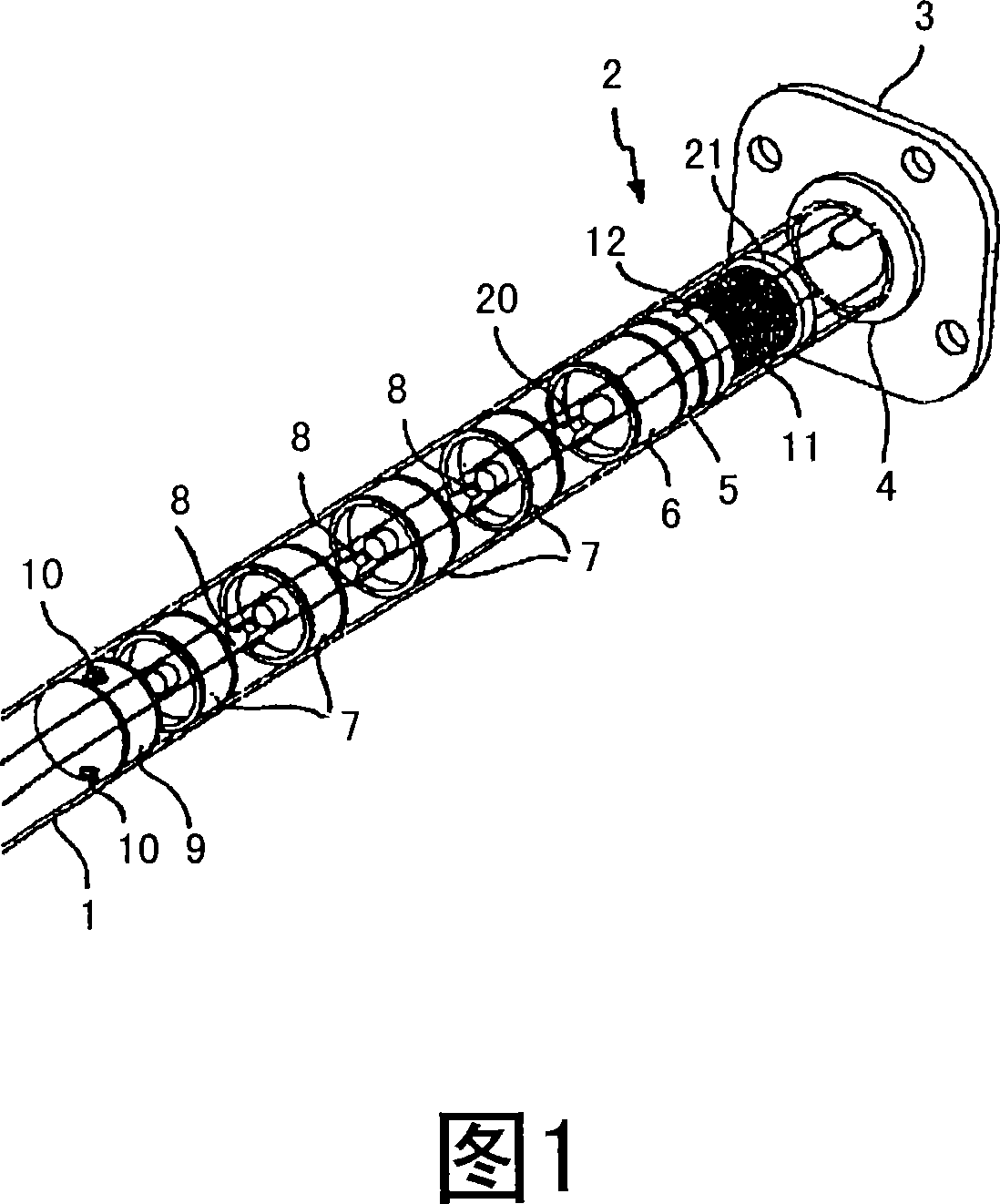

[0026] Figure 1 shows a perspective view of the components of a roller shade assembly for returning roller shade material (not shown in the figure) in a defined manner to a stowed position at a reduced speed at the end of a winding operation. Although not shown in the figures, the roller blind assembly can be arranged in a known manner between the covering position and the storage position by winding the roller blind material on the winding shaft 1 . The roller blind assembly forms in particular a cargo space covering device for the cargo space of a motor vehicle. However, the roller blind assembly can also be used in any other application, for example as a roller blind assembly for a vehicle or a windshield for a window.

[0027] According to an exemplary embodiment of the invention, the roller blind assembly is preferably wound by means of a spring drive (not shown), which can be arranged inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com