Filling system and bag conveying device for the system

A transfer device, bag technology, applied in the direction of transportation and packaging, packaging, packaging item types, etc., can solve problems such as bag cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

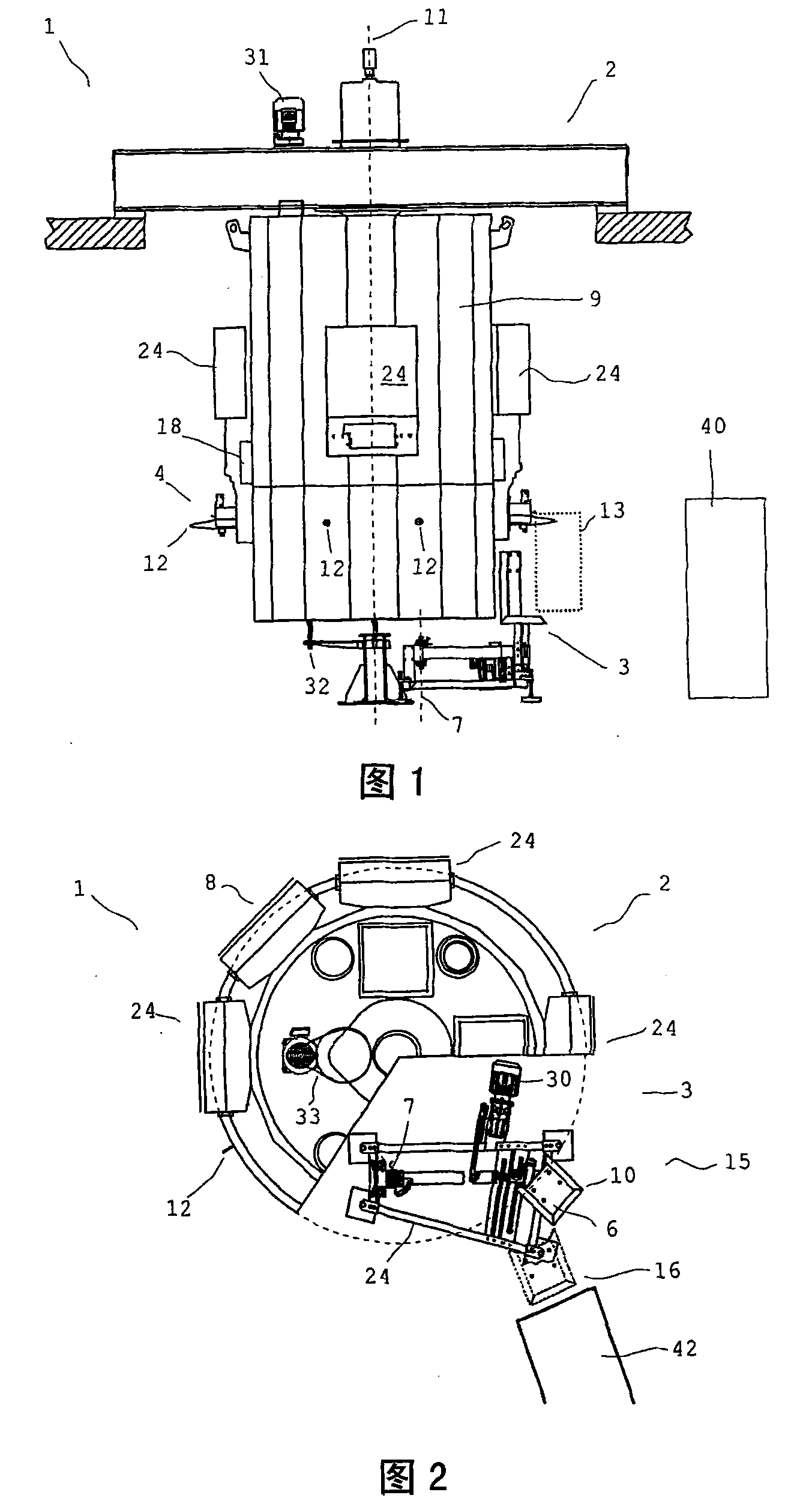

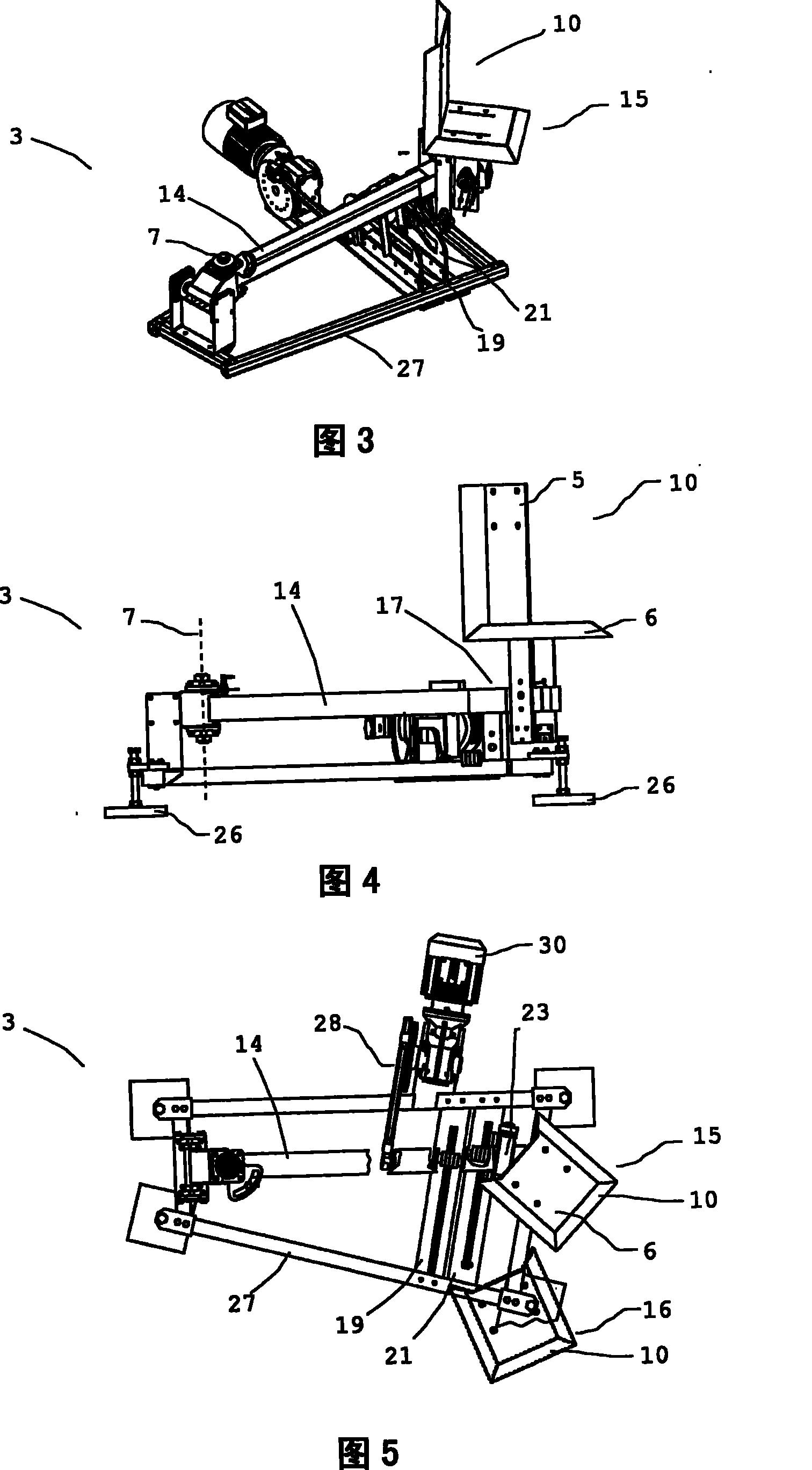

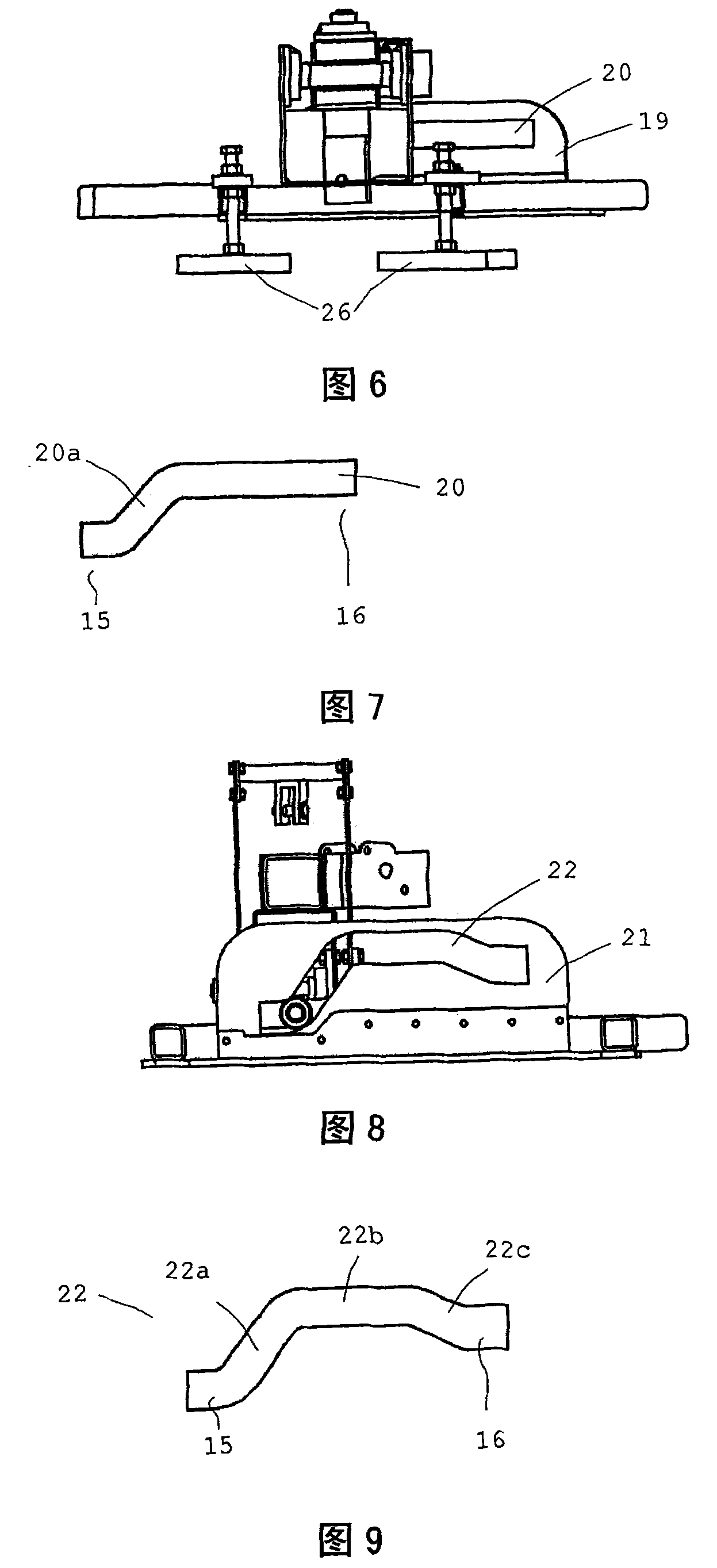

[0063] With reference to said views, an exemplary embodiment of a filling system 1 according to the invention will be described below. Said filling system 1 according to the invention comprises a rotary filling machine 2 and a separate bag transfer device 3 pushing or ejecting filled bags. In this exemplary embodiment, the filling system 1 is used for bagging bulk materials, in particular for bagging construction materials such as cement.

[0064] FIG. 1 shows a side view of the filling system 1 and FIG. 2 shows a top view of the filling system 1 , partly cut away, in order to allow the bag transfer device 3 partly located underneath to be seen.

[0065] The cross-section of the center filler housing 9 is currently configured with 16 corners. The cross-section may also be circular or have a different number of corners.

[0066] The filling machine 2 in this exemplary embodiment can be equipped with up to 8 filling modules 4 each comprising a filling tube 12 . The illustrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com