Hydropowerstation water inlet sand-discharging facility

A technology for water inlet and hydropower station, which is applied in the direction of hydropower station, hydropower generation, traditional hydropower energy, etc., can solve the problems of difficulty in achieving sand removal effect and small scouring funnel range, and achieve good sand removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

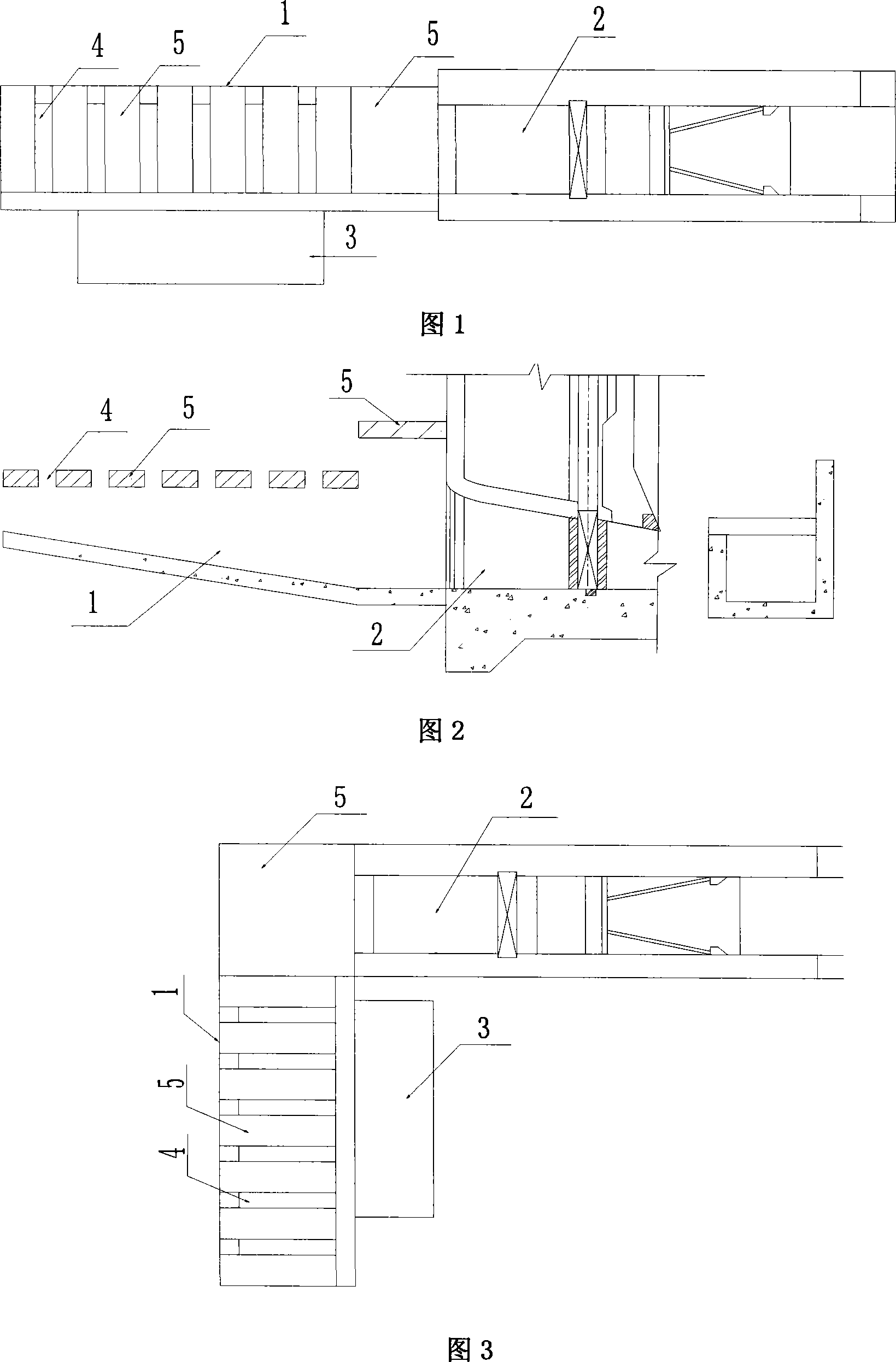

[0013] As shown in Figures 1 and 2, between the sand discharge bottom hole 2 and the water inlet 3 of the power station, a grid-type sand discharge corridor 1 is provided. The top of the corridor 1 is the grid gap 4 and the grid top plate 5, and the bottom is the bottom plate of the sand discharge corridor.

[0014] Also see Fig. 3, also has the same structure in this embodiment.

[0015] Engineering model test results

[0016] The river section where Project A is located is a sandy river. The average annual suspended sediment load at the dam site is 637,000 tons, and the transported sediment load is 191,000 tons. s =2.78t / m 3 , Silt dry bulk density γ s '=1.60t / m 3 , median diameter d 50 =33.3mm, average particle size d pj = 52.9 mm.

[0017] The project is a concrete gravity sluice dam (with flood discharge holes, sand bottom holes, and sewage channels), with a crest elevation of 2471.40m and a maximum dam height of 34.4m. The size of the flood discharge hole and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com