Method for installing and using hydrocyclone diffusing device for grit chamber

A technology of hydrocyclone and diffusion device, which is applied in the direction of separation method, chemical instrument and method, sedimentation separation, etc. It can solve the problems of increasing the chance of sand collision and friction, increasing the difficulty of operation and maintenance, and increasing the aeration device, so as to save Pipe material, best sand removal effect, effect of improving sand removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The patent of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

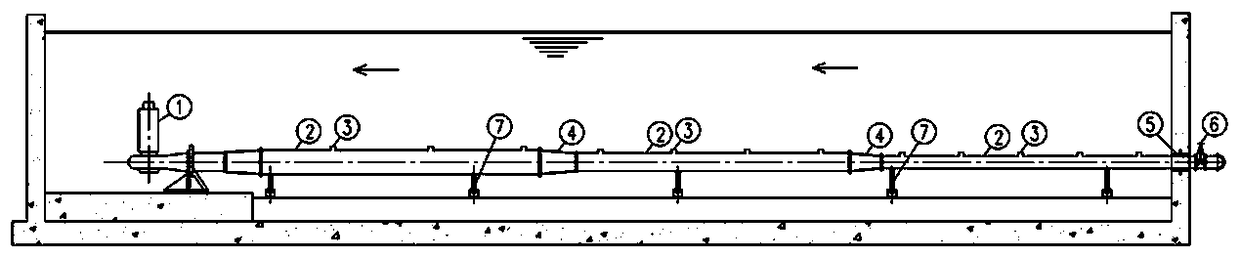

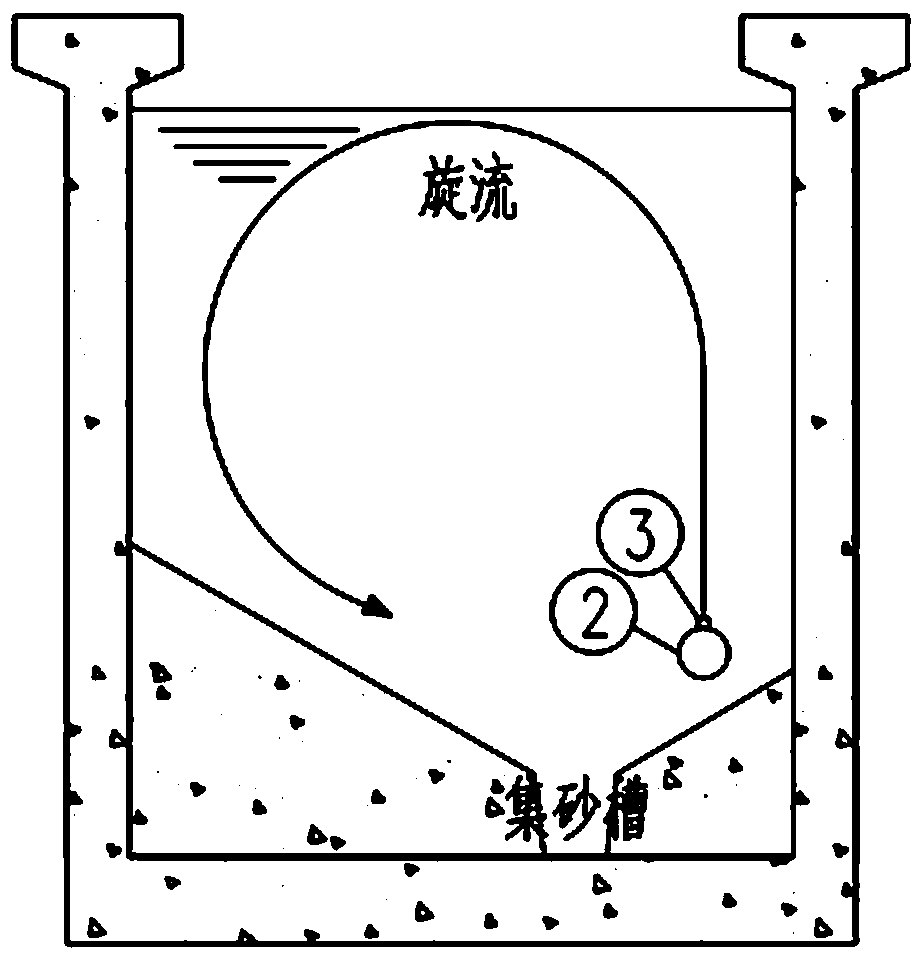

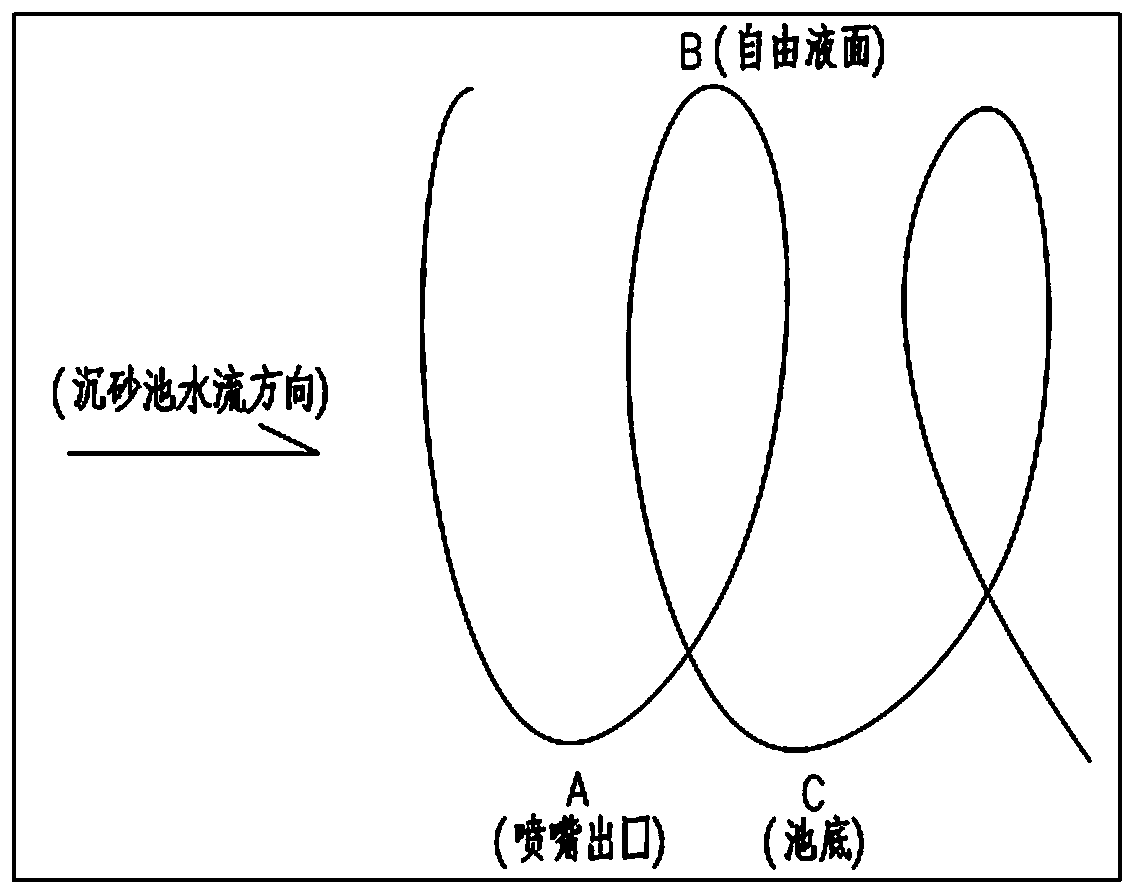

[0031] Such as figure 1 Shown is a hydrocyclone diffusion device for a grit chamber, mainly including a hydrocyclone pump 1 and a hydrocyclone diffusion pipe 2 . The hydrocyclone pump 1 is installed at the water outlet of the grit chamber, presses the sewage into the hydraulic diffusion pipe 2 according to a certain flow rate, and a number of jet nozzles 3 are installed on the diffusion pipe 2 according to a certain interval, and the sewage in the diffusion pipe flows from the The jet nozzle 3 sprays out to form a vertical swirl, and superimposed with the horizontal flow along the length direction of the pool to form a helical flow (such as figure 2 shown), so as to achieve the purpose of efficiently separating sand particles.

[0032] The hydraulic diffusion pipe 2 is fixed on the bottom side of the pool through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com