Municipal sewage desanding device and desanding method

A technology for urban sewage and sewage, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems affecting the normal operation of the digester and biogas production, and the high cost of sewage treatment equipment loss , Sand removal effect cannot be guaranteed, etc., to achieve the effect of simple structure, high degree of automation, and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

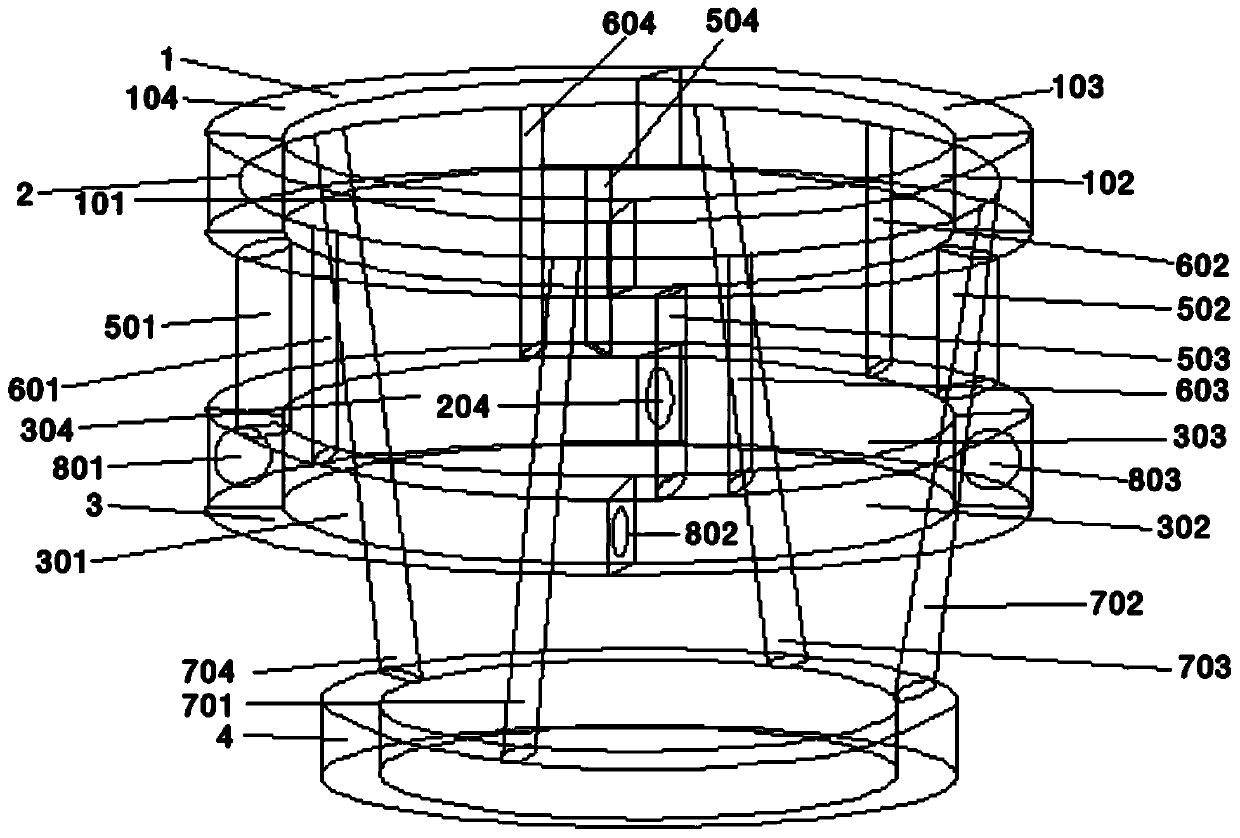

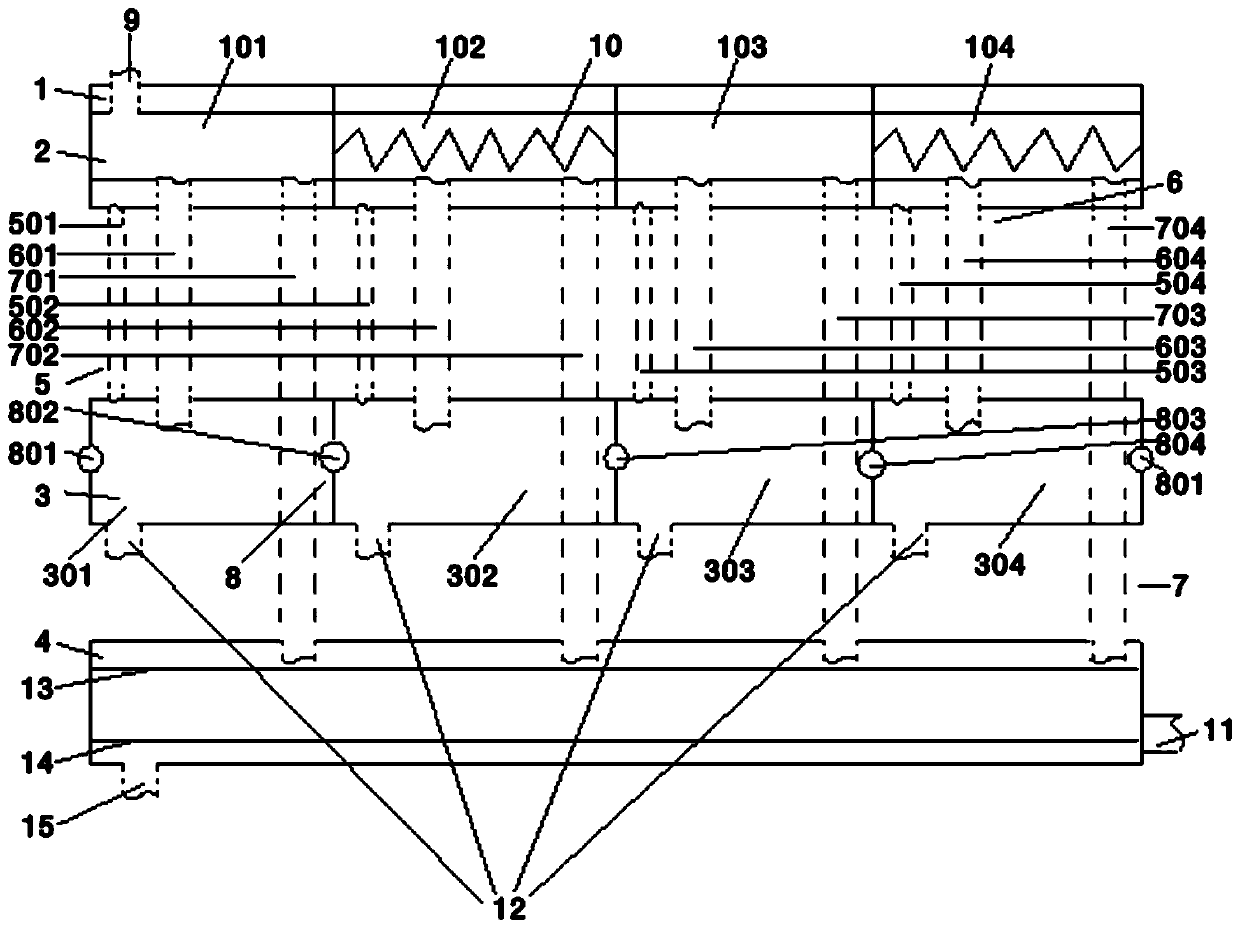

[0031] see Figure 1-3, in an embodiment of the present invention, an urban sewage sand removal device includes a water collection unit 1, a sand removal unit 2, a water storage and return unit 3, and a sand collection unit 4. The water collection unit 1 contains a circulation The desanding unit 2 is statically and dynamically connected alternately. The desanding unit 2 filters the mud and sand in the sewage. The upper left of the water collection unit 1 is provided with a water inlet 9. The sewage outlet 9 is used for the entry of sewage. The desanding unit 2 The inside of the sand unit 2 is provided with a spiral agitator 10, which is used for agitation of sewage to help sand removal. The lower part of the water collection unit 1 is connected with the water storage and return unit 3 through the outlet pipe 5, and the outlet pipe 5 is used for the transmission of sewage The bottom of the desanding unit 2 is connected with the water storage and return unit 3 through the return...

Embodiment 2

[0038] Water outlets 12 are provided below the primary static desanding water storage unit 301 , primary cyclone desanding water storage unit 302 , secondary static desanding water storage unit 303 , and secondary cyclone desanding water storage unit 304 , when the value of the mud and sand induction plate 14 reaches the standard, the corresponding water outlet 12 is opened, and the sewage enters the next processing unit.

[0039] After the mud and sand transported by the sand removal unit 2 through the sand conveying pipe 7 reaches the mud and sand induction plate 14, when the mud and sand induction plate 14 senses that the weight of the mud and sand is higher than the standard value, the sewage in the water storage and return unit 3, Through the return pipe 6, under the action of the pressure pump, it is reversely transported to the next stage of desanding treatment unit.

[0040] When the extruding plate 13 completes the desanding treatment of a section of sewage, the mud s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com