Sand draining packer

A technology of sand sealing and sand dredging groove, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as reduced pressure bearing capacity, increased running resistance, and sand stuck, etc., to achieve Reduced entry resistance, dredge cuttings, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

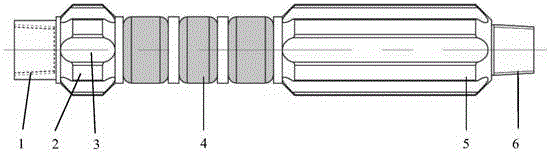

[0013] exist figure 1 In the schematic diagram of the sand dredging packer, the box 1 is fixedly connected to one end of the upper support ring 2, and the other end of the upper support ring is connected to one end of the center pipe with the rubber bucket 4, and the The other end of the central tube is connected with one end of the lower support ring 5, and the other end of the lower support ring is connected with the male buckle 6. The diameters of the upper support ring and the lower support ring are equal, and the circumferential surfaces of the upper support ring and the lower support ring are uniform. Six axial sand dredging grooves 3 are provided, and the diameter of the rubber barrel is smaller than the diameters of the upper support ring and the lower support ring.

[0014] The present invention can be connected in the middle of casing pipe or oil pipe. Connected in the middle of the casing for multi-packer casing string completion in open-hole horizontal wells; conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com