A multi-stage pipeline automatic sand removal device with tree branch structure

An automatic drainage and pipeline technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of lack of comprehensiveness and systematization, and achieve the effect of significant sand drainage, energy saving and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

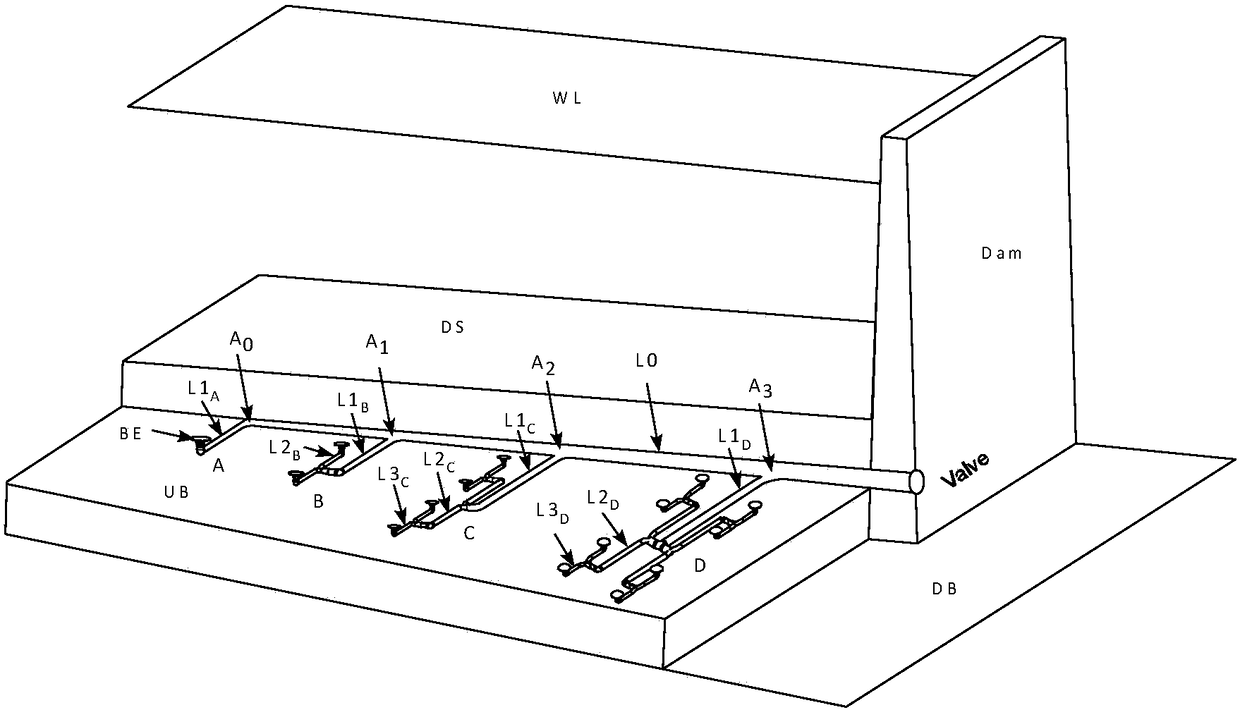

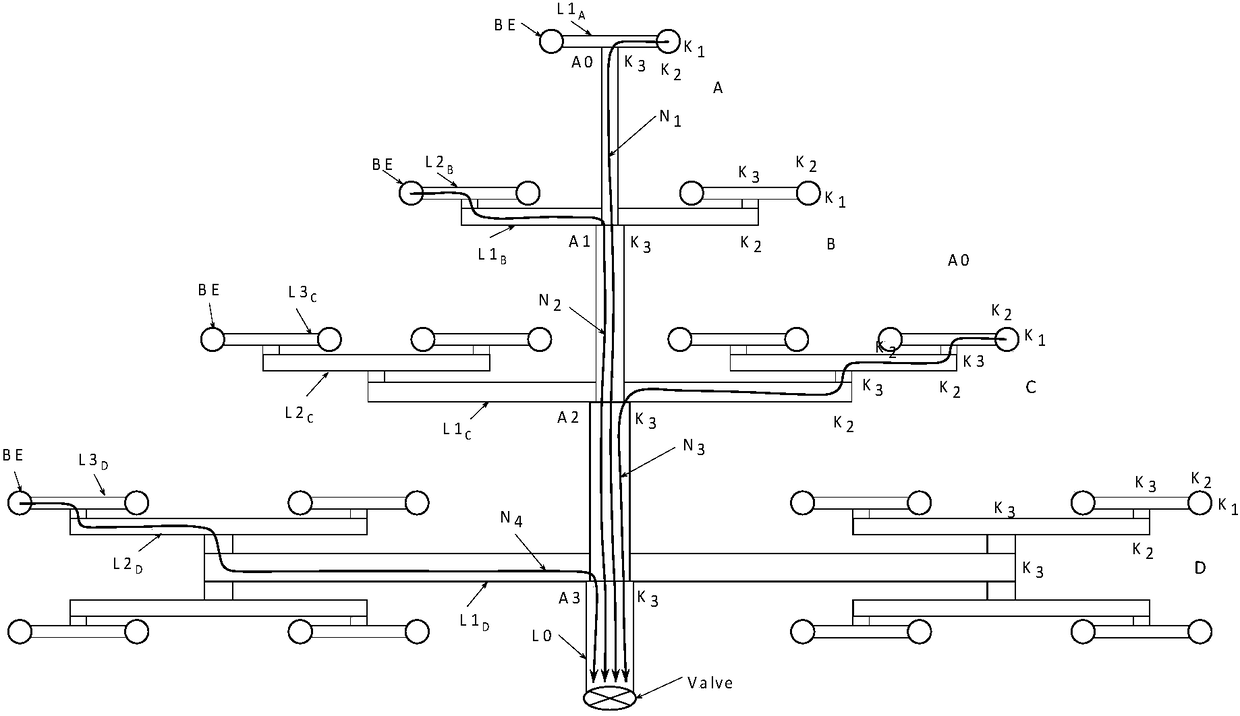

[0023] Embodiment one: lay out this device on the riverbed of the area in front of the dam of the reservoir (UB in the figure is the riverbed upstream of the reservoir, DB is the riverbed downstream of the reservoir, WL is the water surface), the overall layout is as follows figure 1 , the whole device of this embodiment is a tree branch structure arranged symmetrically, only the right half structure of the device is schematically drawn in the figure, and the left half structure is buried below the silted sand surface DS.

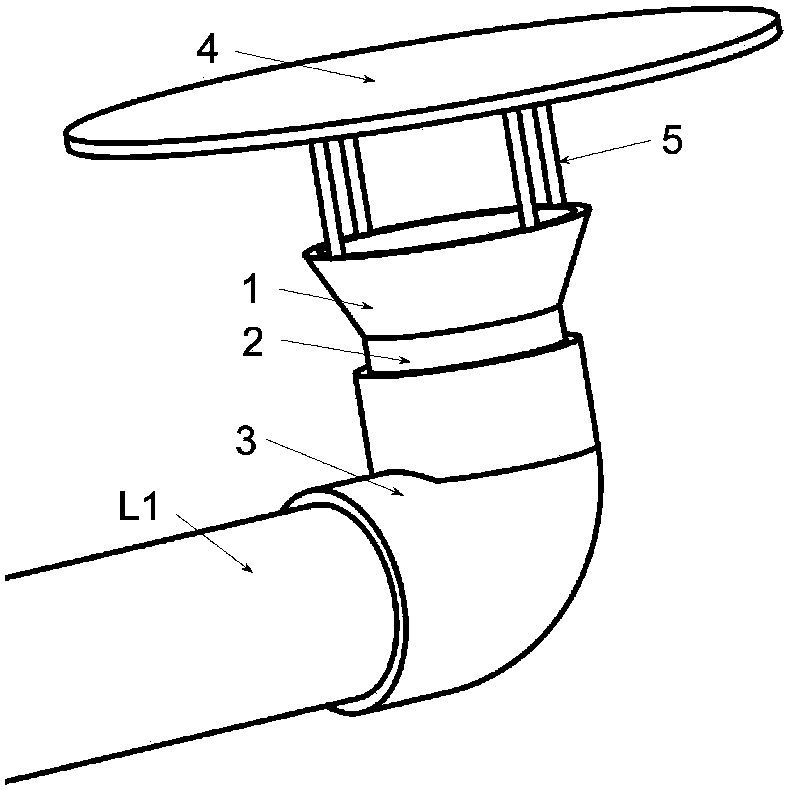

[0024] The main components of the device in this embodiment include multiple identical sand inlet heads BE, a branch structure multi-stage pipeline composed of the main sand delivery pipeline L0 and multi-level branch pipelines A, B, C, and D, and an outlet valve Valve; wherein, The main sand delivery pipeline L0 is arranged on the riverbed in front of the reservoir dam along the direction of water flow. There are two multi-level branch pipelines A, B, C, an...

Embodiment 2

[0058] Embodiment two: the overall structure of the sand discharge device of this embodiment is as follows Figure 4 As shown, the difference from the sand removal device described in Embodiment 1 is that the branch-structured multi-stage pipeline of this embodiment is composed of a main sand conveying pipeline L0 of equal cross-section and 3 groups of identical multi-level branch pipelines E, and 3 groups are more The first-level branch pipes E are arranged in a zigzag shape; each group of multi-level branch pipes E consists of the first-level branch pipes L1 E , 7 identical second-level branch pipelines L2 E , 14 identical third-level branch pipelines L3 E Composition, 7 second-level branch pipelines L2 E At common branch confluence port A 4Arranged in a circular divergence, and at the end of the branch confluence port and the first-level branch pipeline L1 E Connected, 14 tertiary branch pipes L3 E Evenly divided into 7 groups, each group has 2 third-level branch pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com