Sealing device

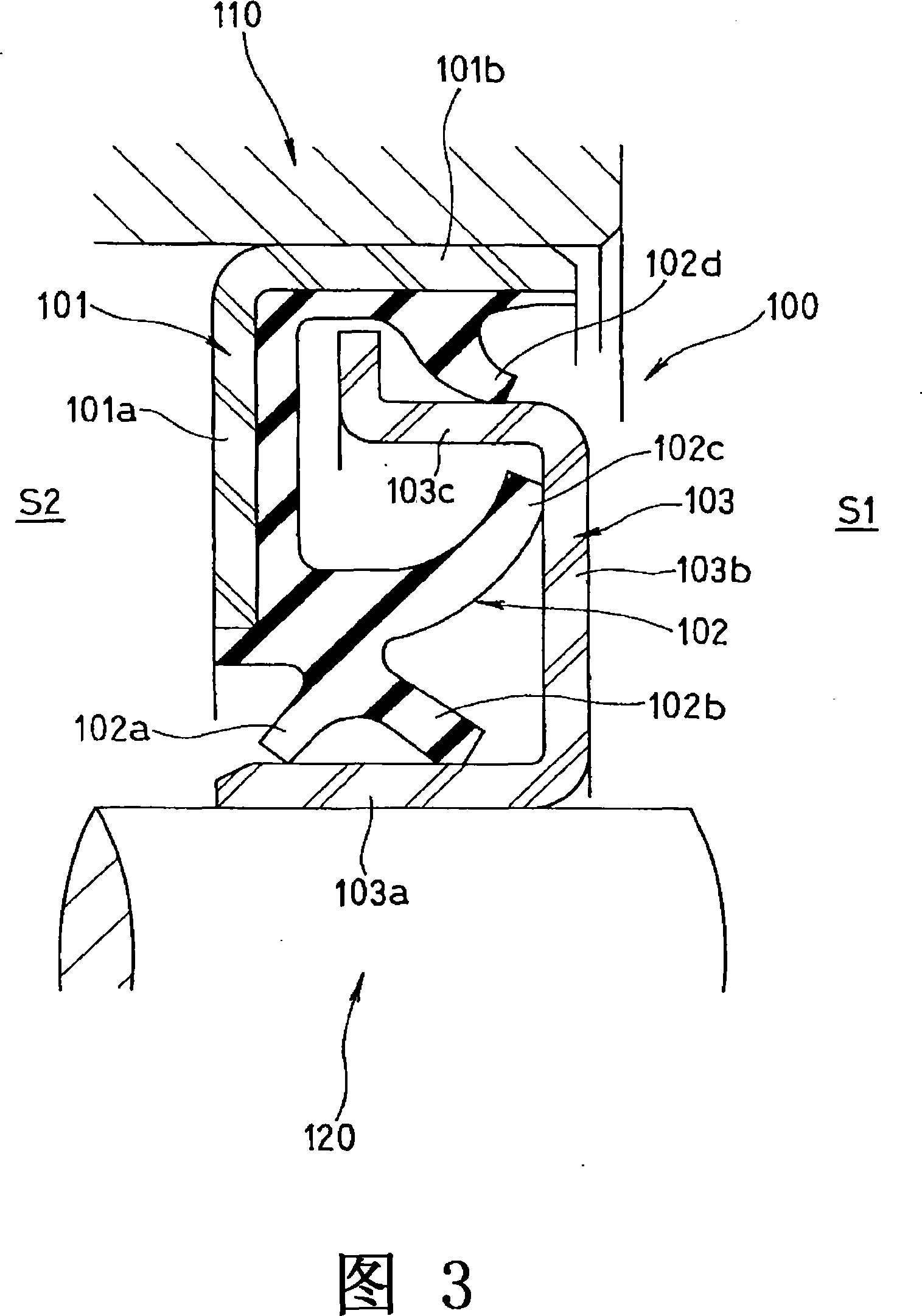

A sealing device and sealing ring technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as breakage, deformation, damage to the peripheral sealing lip 102, etc., to improve sealing performance, excellent sealing performance, prevent damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

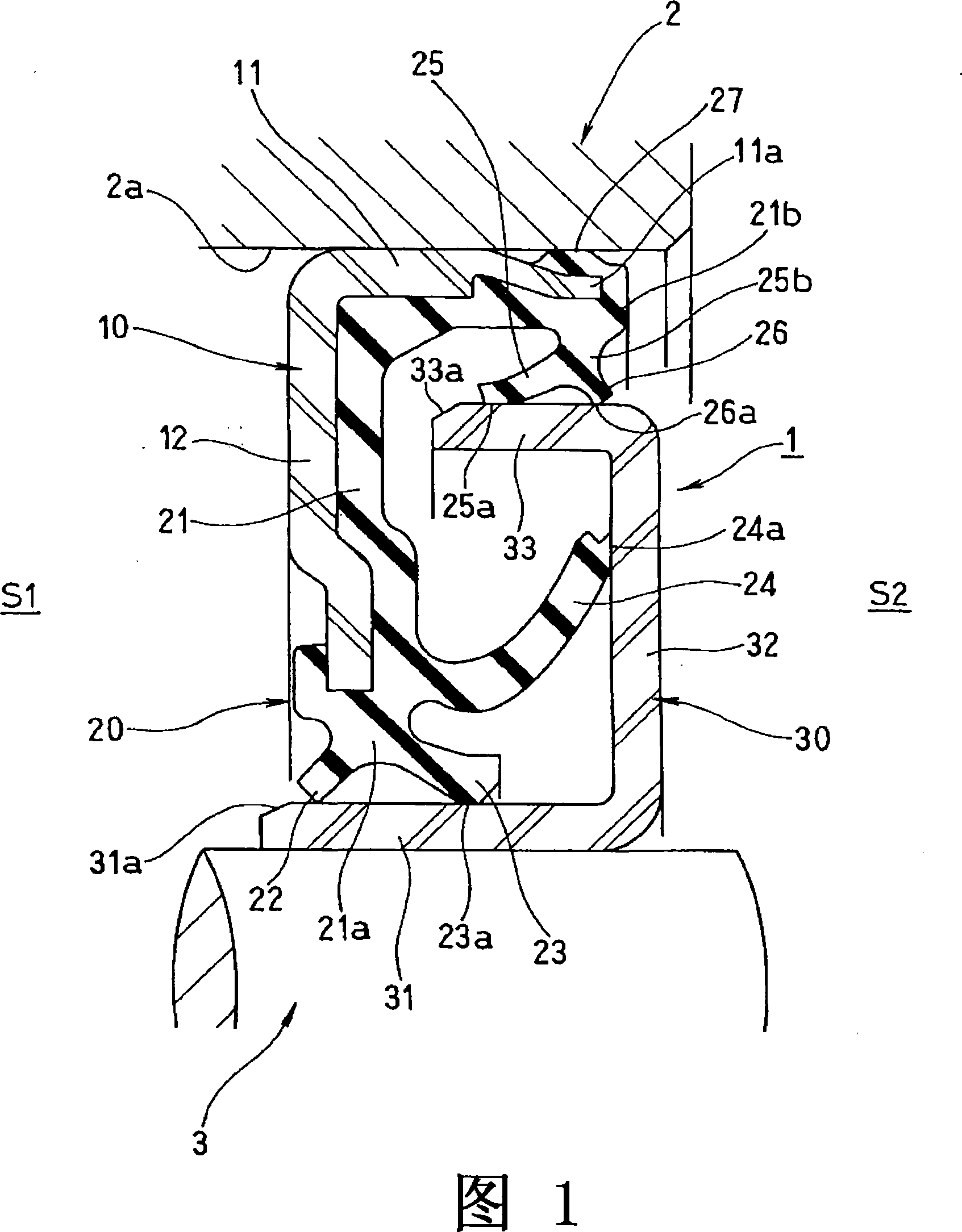

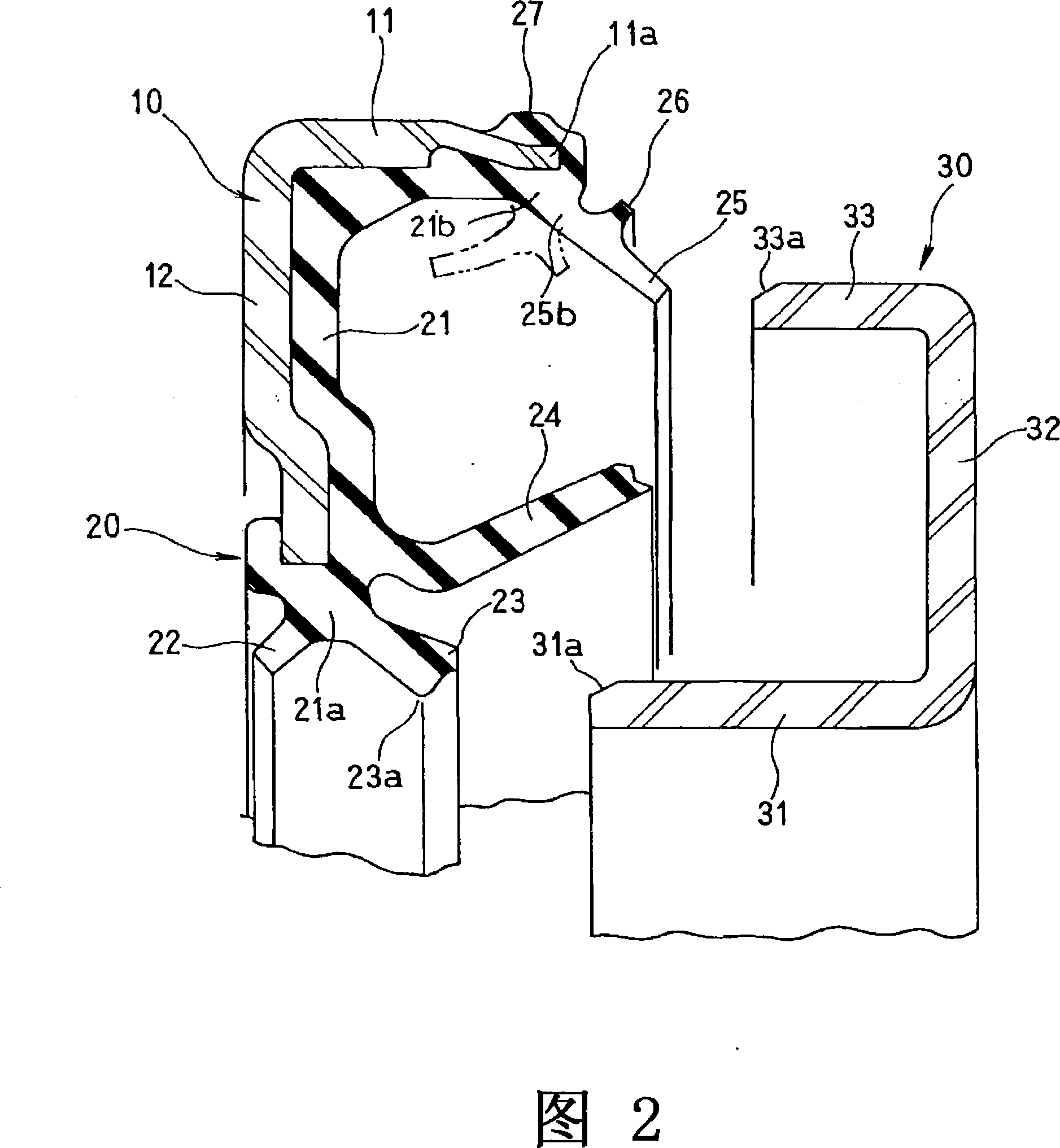

[0042] Preferred embodiments of the sealing device according to the present invention will be described below with reference to the accompanying drawings. First of all, Fig. 1 is a half-sectional view showing that the sealing device according to the present invention is cut by a plane passing through the axis, and Fig. 2 is a half-sectional view showing that the sealing device according to the present invention is also cut by a plane passing through the axis. A half-sectional view of the first sealing ring and the second sealing ring in a separated state.

[0043] In Fig. 1, symbol 1 is the sealing device according to the present invention, 2 is the outer peripheral side parts (such as the bearing outer ring in the running parts of automobiles or agricultural machinery, construction machinery), and 3 is the inner peripheral side parts (such as the above-mentioned bearings) inner circle). The sealing device 1 is composed of a mounting ring 10 mounted on the outer peripheral me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com