High viscosity fluid microscale spraying glue dropping machine

A spray point, high viscosity technology, applied in liquid spray devices, spray devices, etc., can solve the problem that the research on micro spray technology of high viscosity fluid is still blank, etc., and achieve the effect of high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

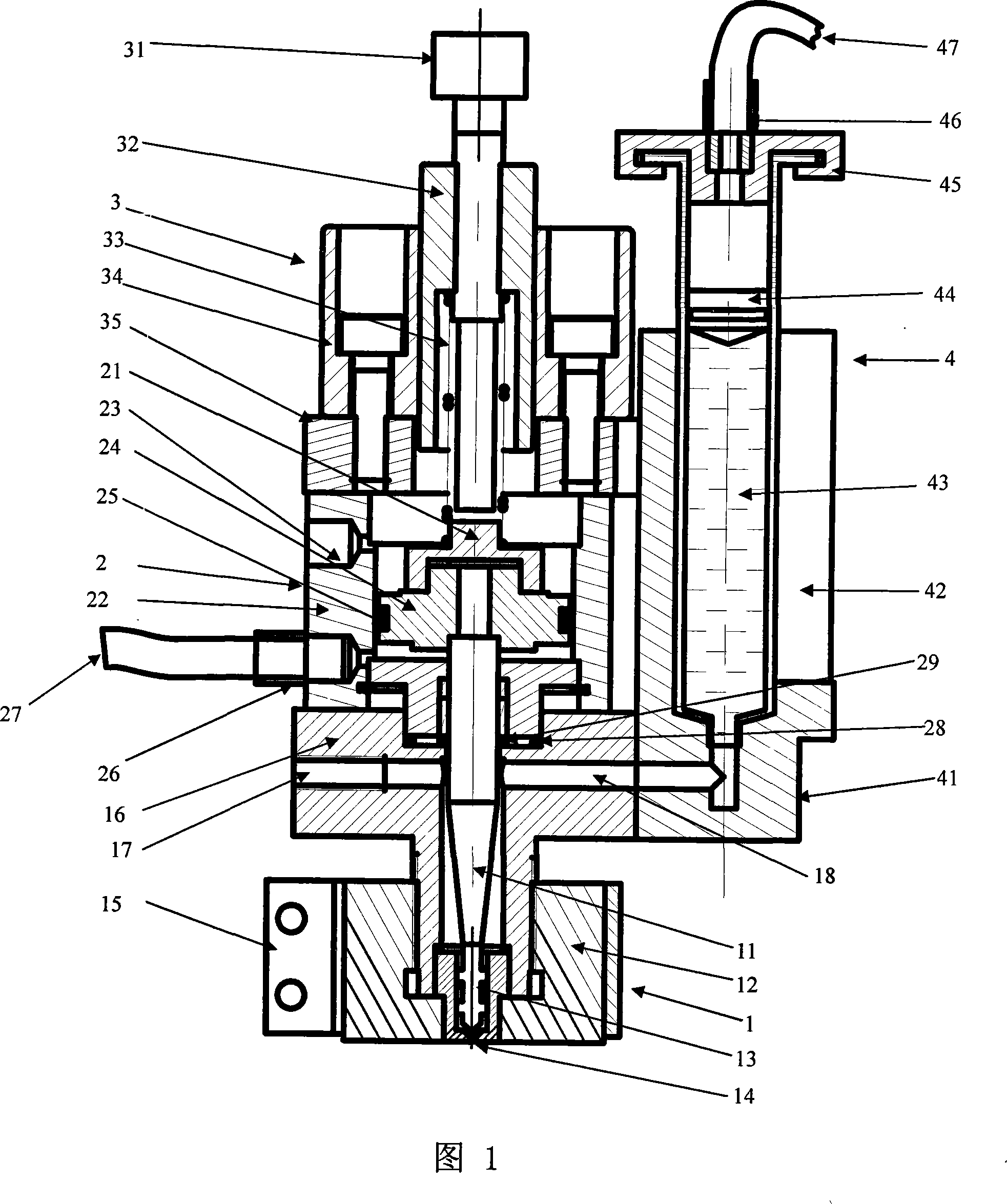

[0017] As shown in FIG. 1 , the present invention consists of four parts: injection mechanism 1 , drive mechanism 2 , stroke and preload adjustment mechanism 3 , and feeding mechanism 4 .

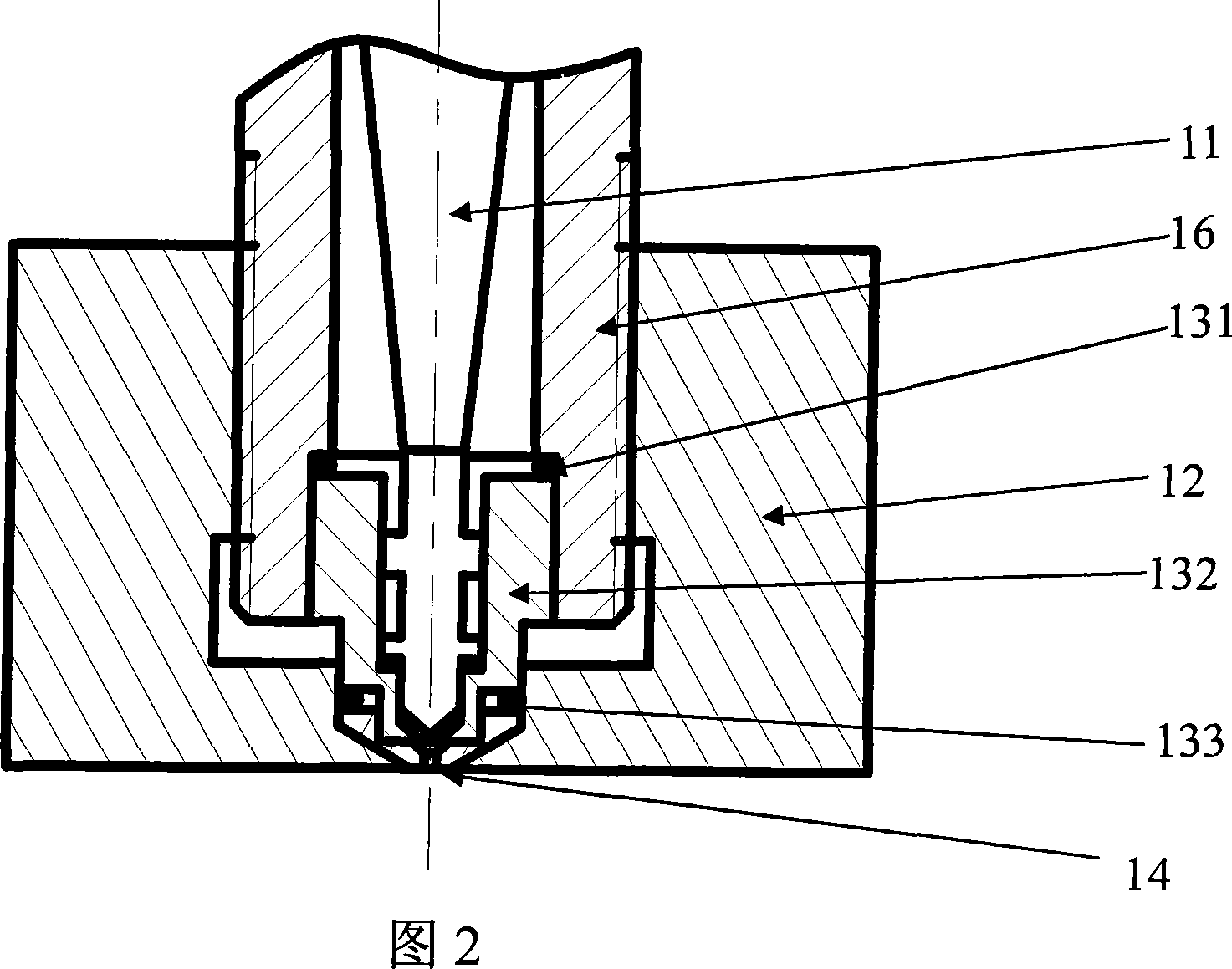

[0018] The injection mechanism 1 includes a cavity 16 and a valve stem 11 arranged inside the cavity 16 , the upper end of the valve stem 11 is connected to the drive mechanism 2 , and the lower end is provided with a spray head 13 . A feed channel 18 is provided on the side of the cavity 16, one end of which communicates with the feeding mechanism 4, and the other end communicates with the gap between the cavity 16 and the valve stem 11, for passing the fluid from the feeding mechanism 4 through The valve stem 11 is conveyed to the injection head 13 . An exhaust channel 17 is also provided on the side of the cavity 16 for exhausting the air in the injection mechanism 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com