Automatic die cutting machine safety protecting device

A technology for safety protection devices and die-cutting machines, which is applied in engineering safety devices, mechanical equipment, metal processing, etc., and can solve the problems that micro switches are easily damaged and cannot meet the safety protection requirements of automatic die-cutting machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

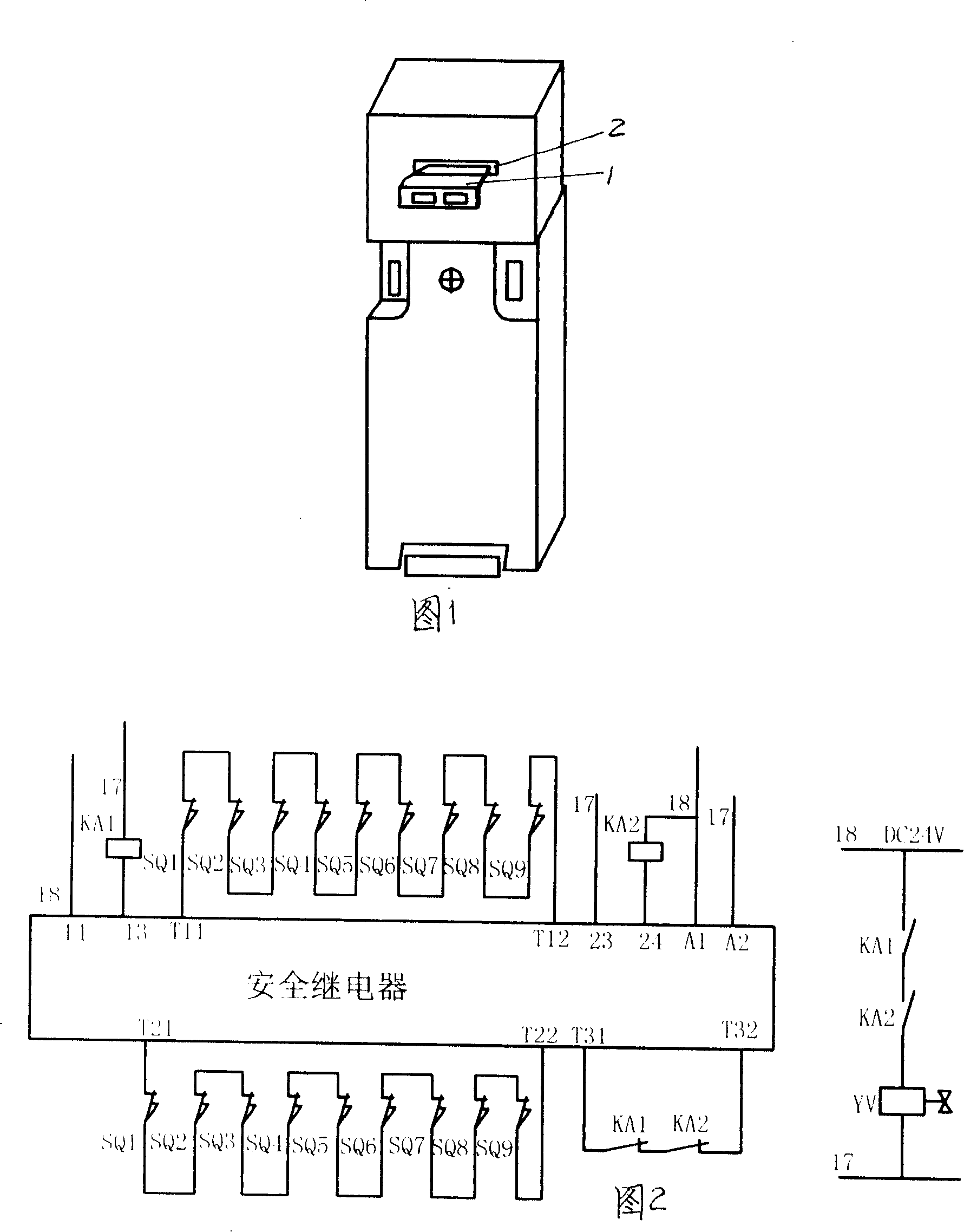

[0005] The present invention is described in detail in conjunction with the above drawings. In order to overcome the shortcoming that the existing micro switch is easily damaged, the switch body is fixed on the frame, the strip hole 2 on the switch is matched with the key 1, and the key is connected with the window. (see Fig. 1) respectively be provided with two groups of normally closed contacts in the switch, die-cutting machine of the present invention has nine window doors, the switch SQ1 of each window door, SQ2, SQ3, SQ4, SQ5, SQ6, SQ7, SQ8, There are two sets of normally closed contacts on each of SQ9 and SQ9, and the two ends of one set of normally closed contacts are connected to the terminals T11 and T12 of the safety relay respectively after being connected in series with each other, and the other set of normally closed contacts are connected in series with each other. The two ends of the coil KA1 are respectively connected to the terminals T21 and T22 of the safety ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com