Cable-stayed bridge inclined dragline and steel main bear armtie type anchoring structure

A technology of anchoring structures and anchoring slabs, applied in cable-stayed bridges, bridge forms, bridges, etc., can solve the problems of unreliable guarantee of structural safety, difficult to find defects, complicated force transmission channels, etc., and achieve the utilization of materials The effect of improving efficiency and economy, novel structure, and simple and clear way of force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

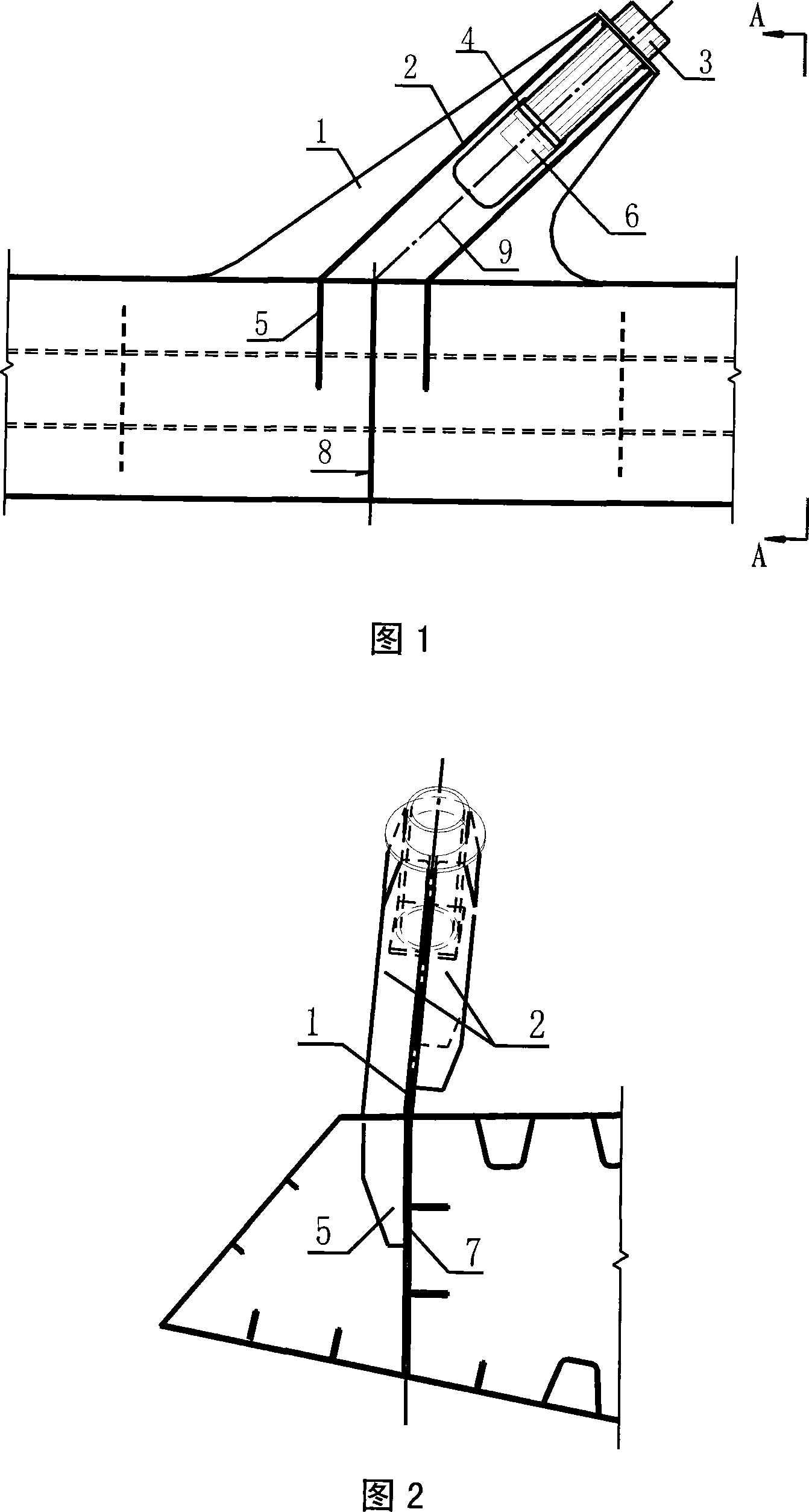

[0021] With reference to Fig. 1, 2, the present invention is made up of anchor stay plate 1, anchor pipe 3, anchor plate 5, anchor stay plate stiffener 2 etc., and anchor stay plate 1 is directly welded on the steel girder top surface, makes the stay cable Both the hanging installation and its anchoring system are located on the bridge deck, which is convenient for operation and maintenance. The stay cable anchor head 6 is anchored on the anchor pad 4 . The lower end of the anchor plate 1 is welded on the top surface of the steel girder. It must coincide with the longitudinal web 7 of the steel beam during welding. The lower stiffener 5 of the steel bridge deck is welded at the lower end of the plate stiffener 2 .

[0022] The production process of the present invention is as follows: first, the anchor backing plate is welded to the anchor pipe in the factory; secondly, penetration welding is carried out with the anchor tie plate, and after passing the flaw detection inspecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com