A flexible connection device and masonry method for a masonry filling wall and a main frame

A main frame, flexible connection technology, applied in buildings, building components, building structures, etc., can solve problems such as structural performance effects, and achieve the effects of enhanced seismic performance, clear force transmission paths, and firm connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

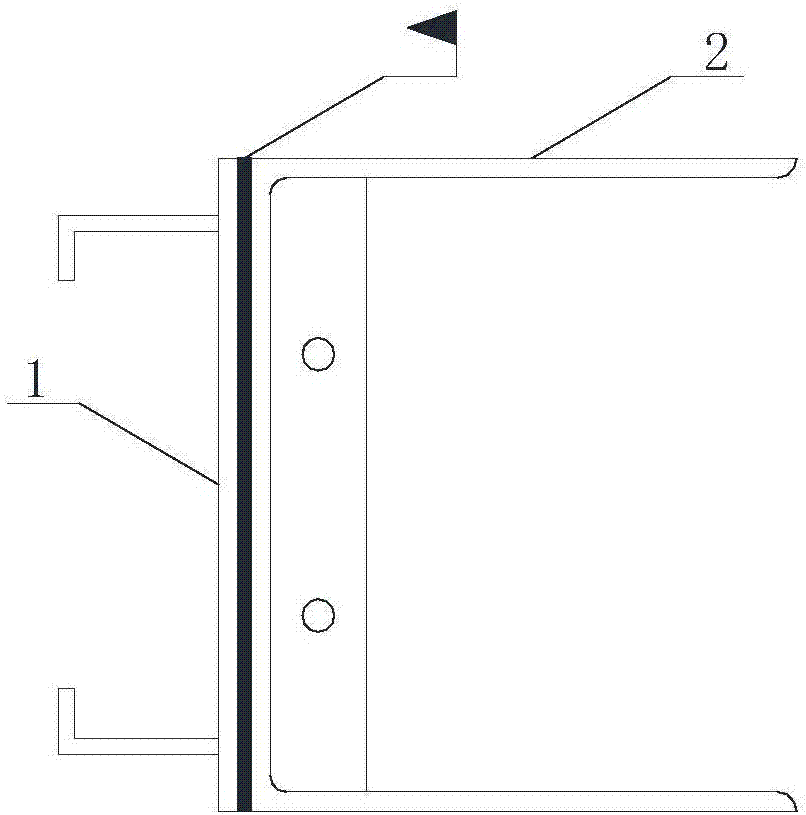

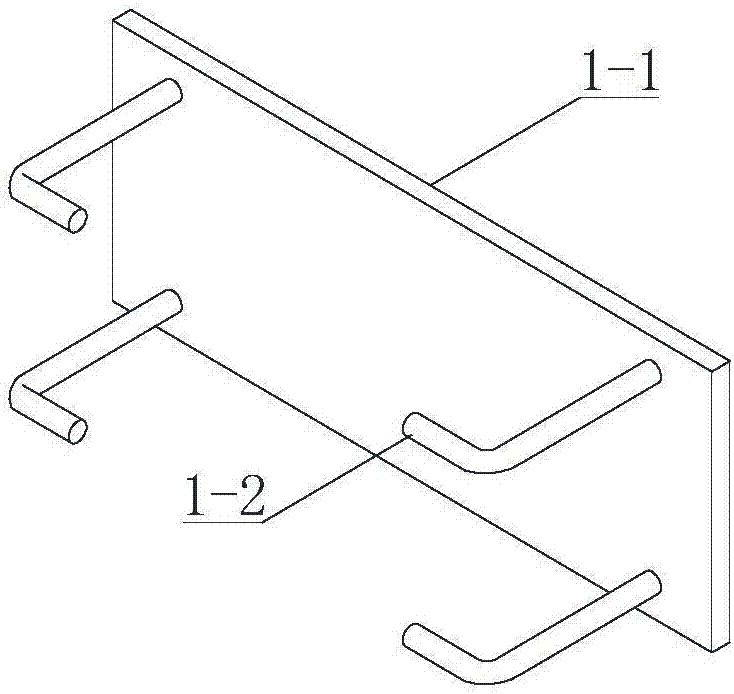

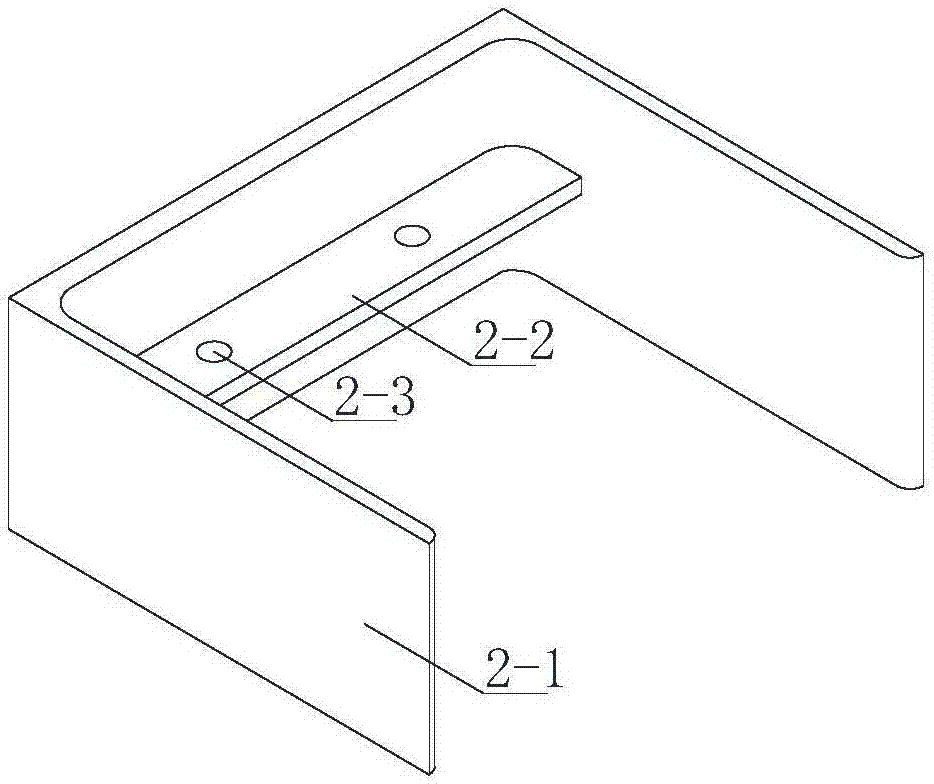

[0037] Example: such as figure 1 As shown, the present invention is a flexible connection device between a masonry infill wall and a main frame, including a connector A1 that can be pre-embedded in the main frame and a connector B2 connected with the connector A; figure 2 As shown, the connector A is formed by setting four symmetrical L-shaped anchor ribs 1-2 on one side of the vertical plate 1-1; image 3 As shown, the connector B has a U-shaped bayonet 2-1 that can clamp the filling wall 4, and a horizontal plate 2-2 is provided at the bottom of the U-shaped bayonet 2-1, and two symmetrical pull-outs are arranged on the horizontal plate. Knot hole 2-3, the vertical plate of connector A is welded to the bottom plate of U-shaped bayonet 2-1 of connector B on site.

[0038] The horizontal plate 2-2 is welded with the U-shaped bayonet, the width of the horizontal plate is 20mm-30mm, and the length of the horizontal plate is the same as the width of the U-shaped bayonet.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com