Device and method for flexible connection between masonry filler wall and main body frame

A main frame, flexible connection technology, applied in the processing of building materials, building components, earthquake resistance, etc., can solve problems such as structural performance impact, and achieve the effect of enhanced seismic performance, good integrity, and convenient structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

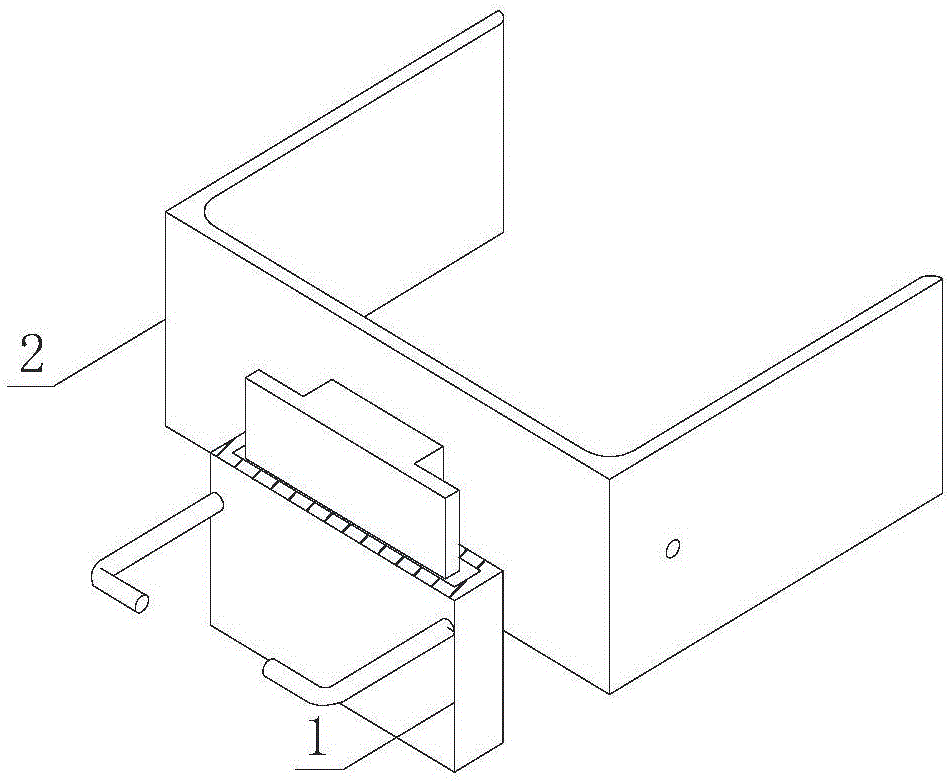

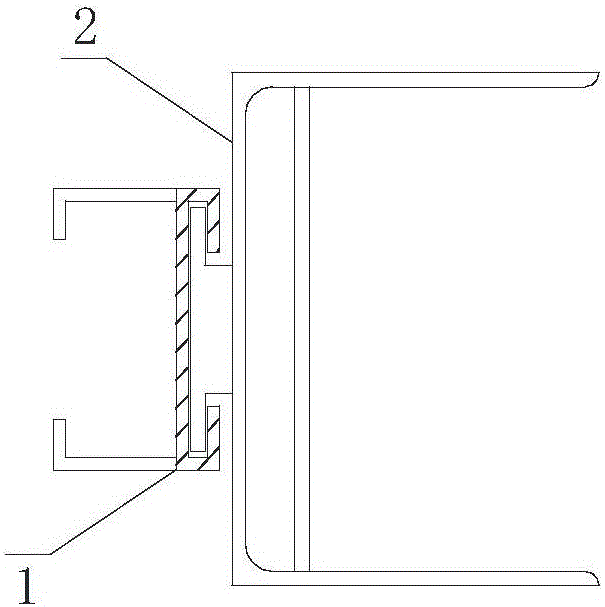

[0037] like figure 1 and figure 2 As shown, the flexible connection device between the masonry filling wall and the main frame of the present invention includes a connecting piece A1 that can be pre-embedded in the main frame and a connecting piece B2 connected with the connecting piece A.

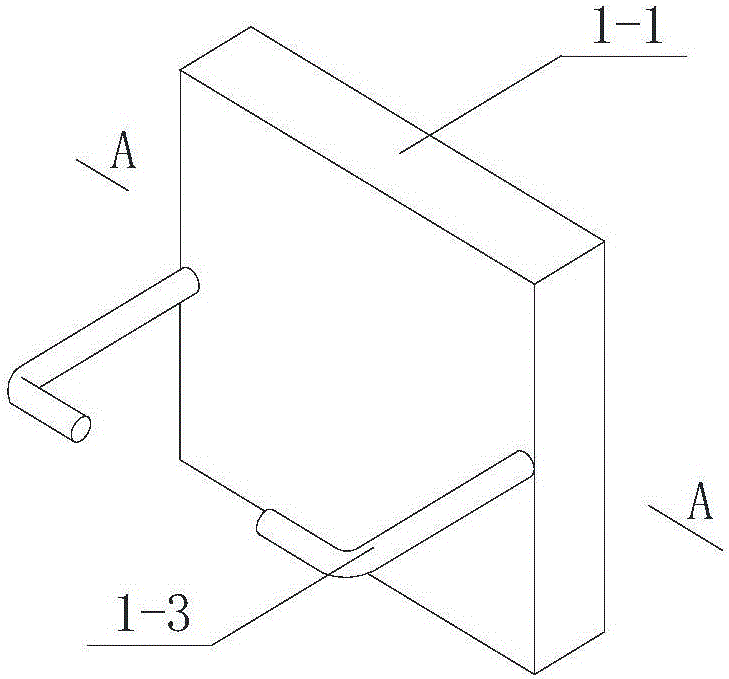

[0038] like image 3 and Figure 4 As shown, the front part of the connector A is a square box 1-1, the inner cavity of the box and the front wall of the box form a T-shaped chute 1-2 that opens outward, and there are two symmetrical L on the back of the box. shaped anchor ribs 1-3.

[0039] like Figure 5 and Image 6 As shown, the front part of the connector B is a U-shaped bayonet 2-1 that can clamp the filling wall 4, and the back side of the bayonet has a button that matches the T-shaped chute and can slide up and down in the T-shaped chute. The T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com