Crankshaft parametric computer modeling system

A computer and parametric technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of large randomness and low production efficiency, and achieve intuitive operation, good compatibility and portability, and good The effect of human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

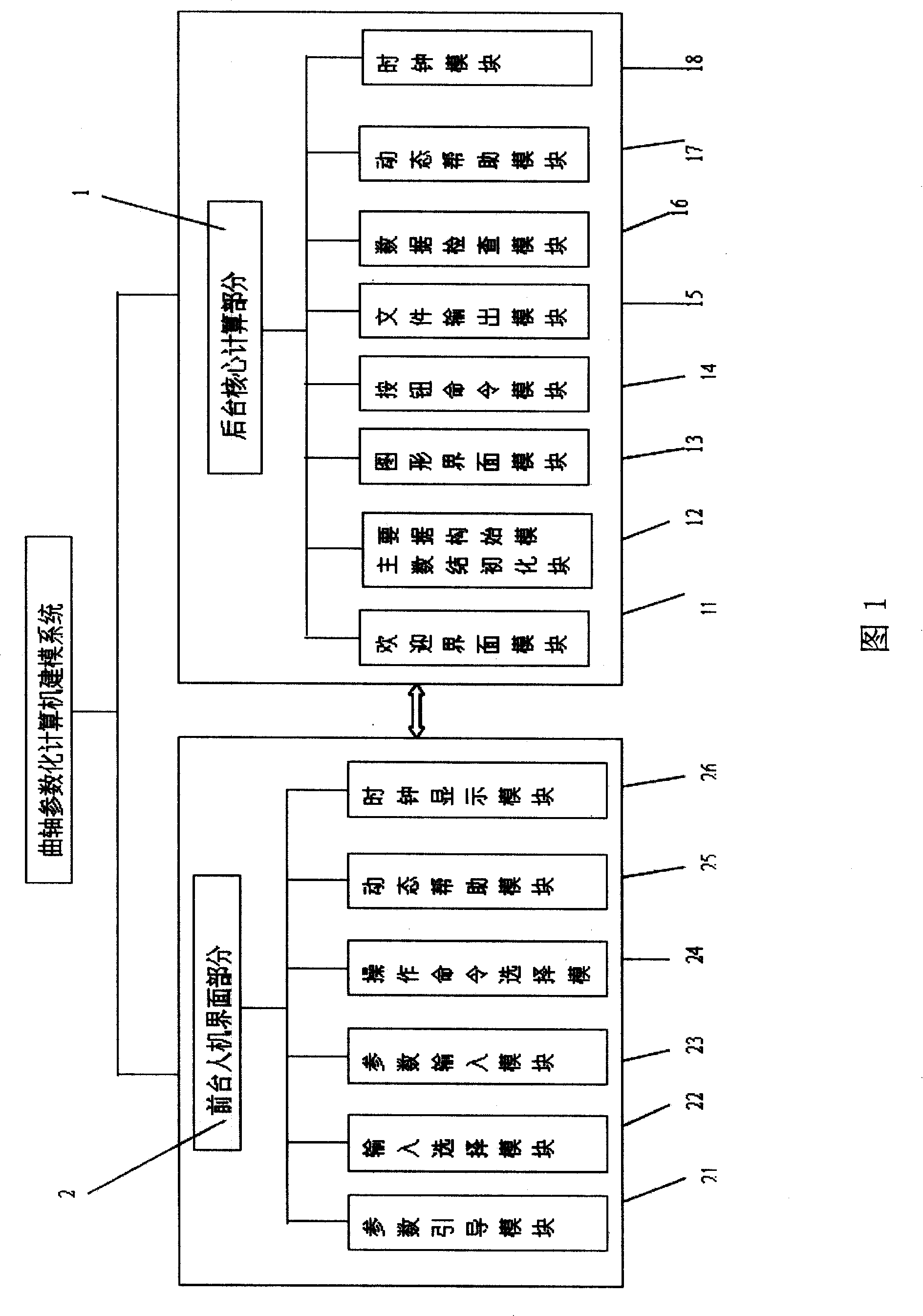

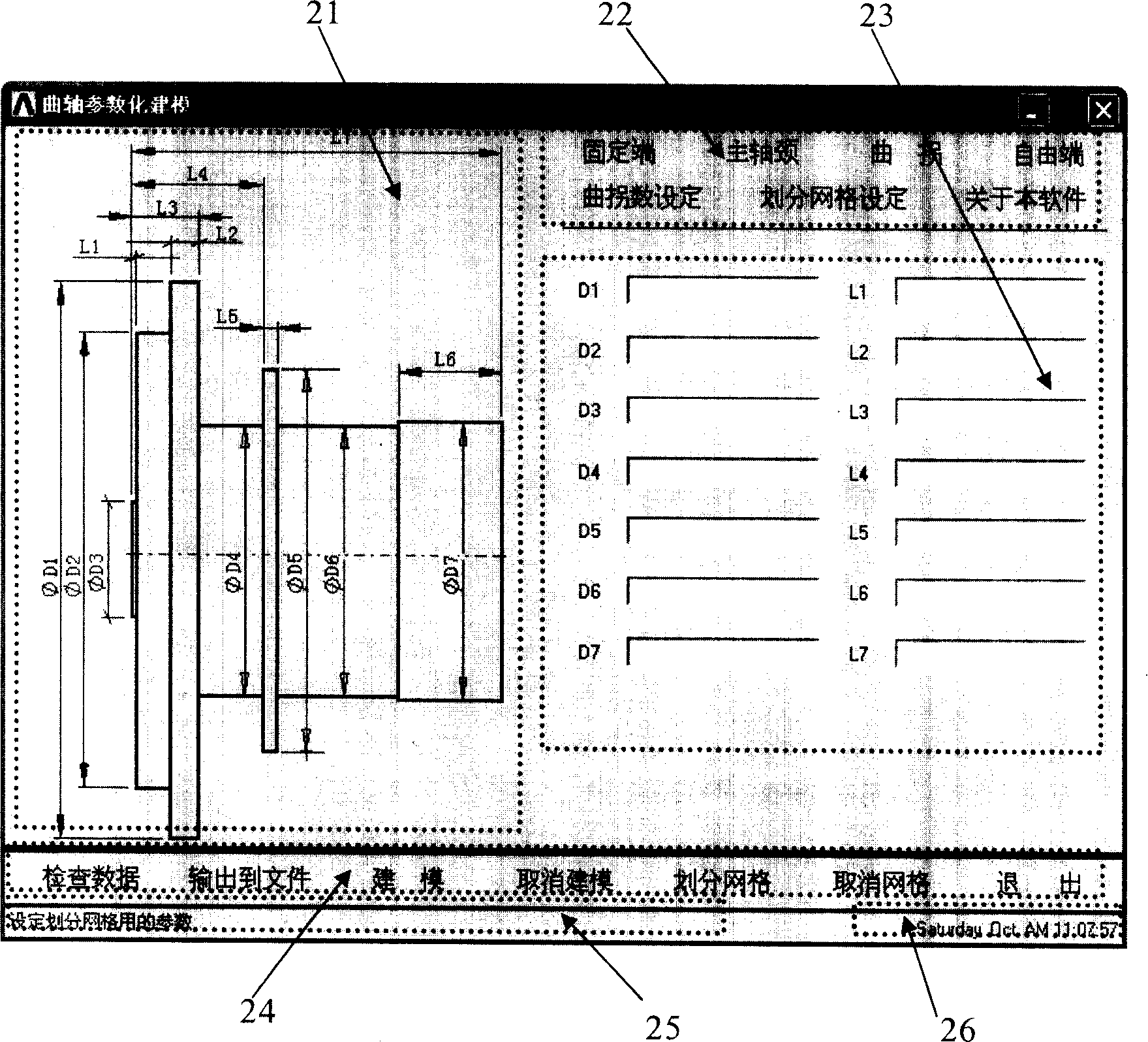

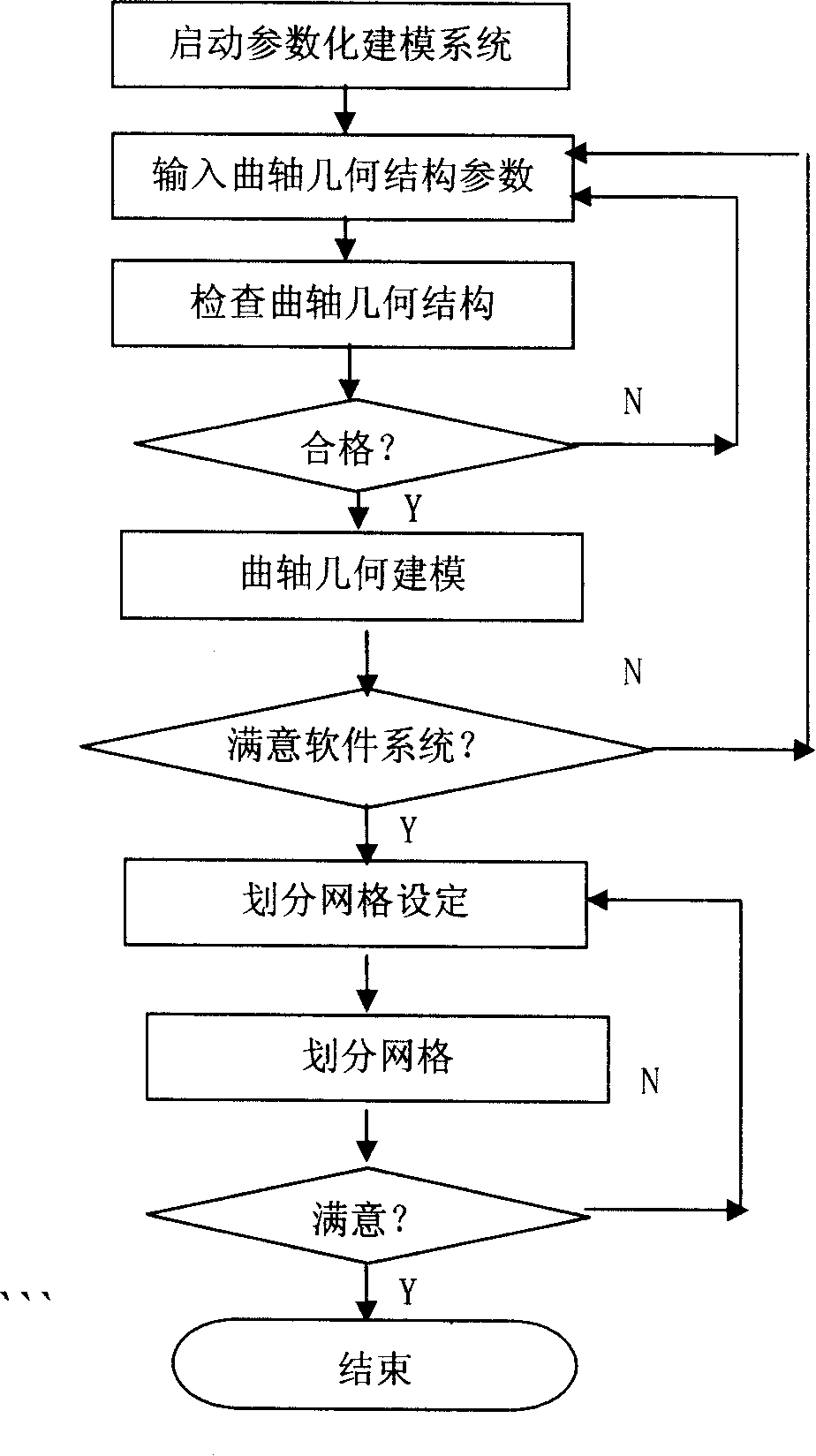

[0020] The crankshaft parametric computer modeling system of the present invention comprises the front stage man-machine interface part 2 under the existing computer analysis system (ANSYS software) and the background core calculation part 1 connected with the front stage man-machine interface part 2, the background Core computing part 1 (seeing Fig. 1) comprises: welcome interface module 11, main data structure initialization module 12, graphical interface module 13, button command module 14, file output module 15, data inspection module 16, dynamic help module 17 and clock Module 18, wherein, the welcome interface module 11 is used to control the welcome interface when the program is started; the main data structure initialization module 12 is used to initialize various data structures when the program is started; the graphical interface module 13 is used to control the front desk of the program Man-machine interface; button command module 14, used to respond to the user's cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com