Polyamic acid component and alignment film produced by the same

A technology of polyamic acid and composition, which is applied in the field of polyamic acid composition and the alignment film made from it, and can solve the problems of general products without structure, inconvenience, liquid crystal alignment property testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

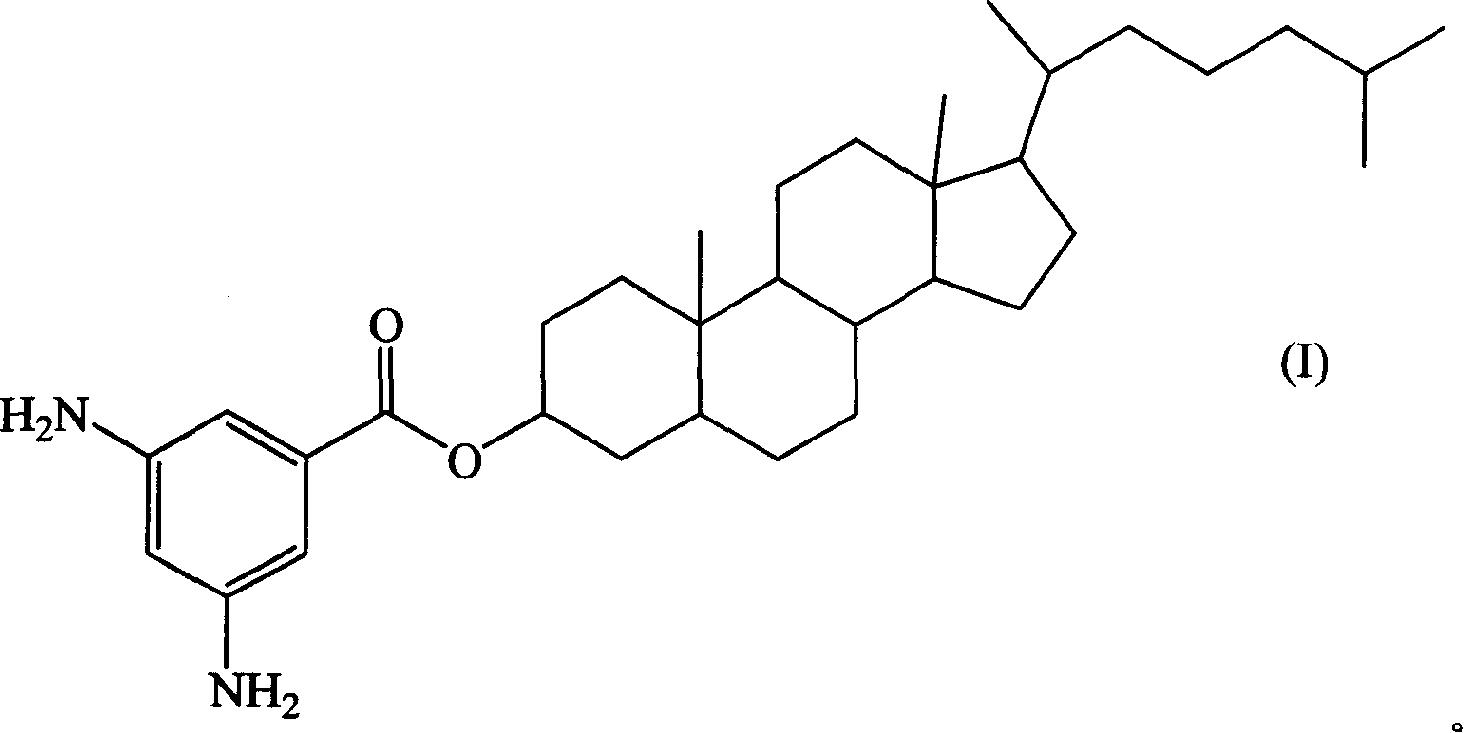

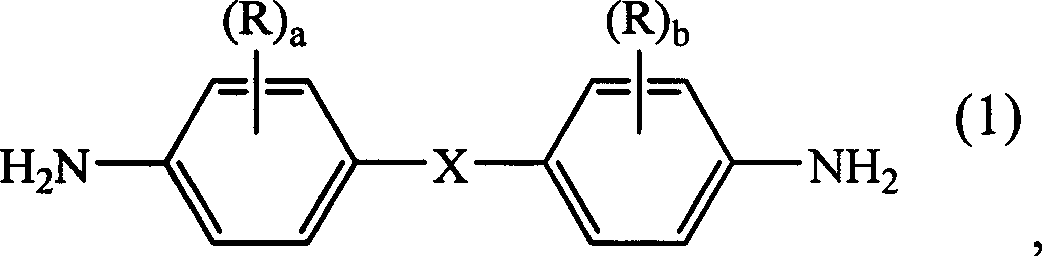

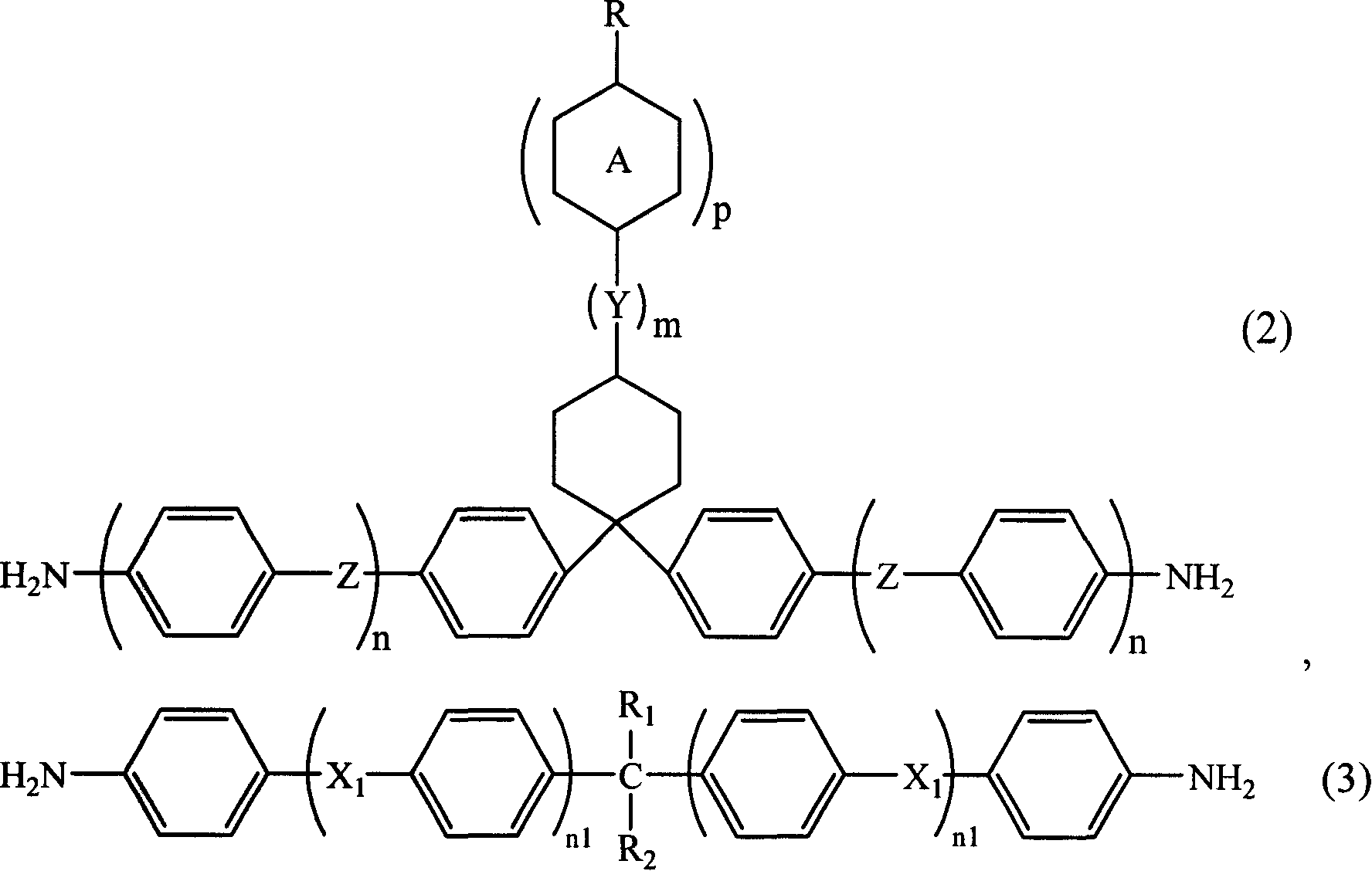

Method used

Image

Examples

Embodiment 1

[0080] [Common production method of Example 1 and Comparative Examples 1-8]

[0081] 1. Preparation of polyamic acid A1~A4 and B1:

[0082] A1: Add 21.17 grams of HDAM and 19.01 grams of BDA to 206 grams of NMP, stir at 20°C for 24 hours, and then add an appropriate amount of the above solvent for dilution to obtain a polyamide with a solid content concentration of 8wt% Acid A1.

[0083] A2: Add 8.75 grams of HDAM, 8.02 grams of BDA, 14.90 grams of BAPB and 8.48 grams of PMDA to 161 grams of NMP, then stir at 20°C for 24 hours, and then add an appropriate amount of the above solvent for dilution to A polyamic acid A2 having a solid content concentration of 8 wt% was obtained.

[0084] A3: Add 4.05 grams of HDAM, 3.71 grams of BDA, 20.70 grams of BAPB and 11.94 grams of PMDA to 162 grams of NMP, then stir at 20°C for 24 hours, and then add an appropriate amount of the above solvent to dilute. A polyamic acid A3 having a solid content concentration of 8 wt% was obtained.

[0085] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com