Film deposition method and device by sputtering

A sputtering equipment, sputtering target technology, applied in sputtering coating, cathode sputtering application, application of magnetic film to substrate, etc., can solve the problem of difficult to increase at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

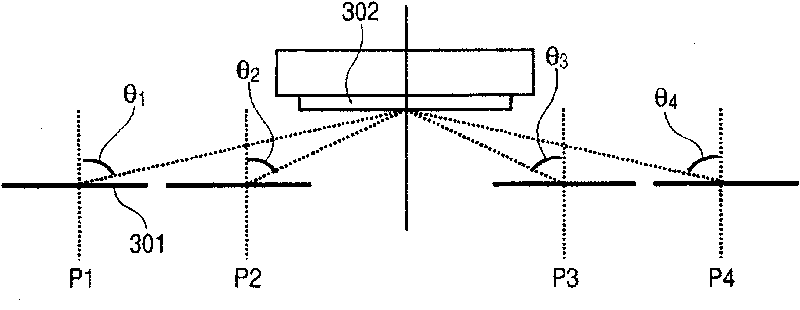

[0082] Figure 4A It is a side view of the first sputtering apparatus 400 according to the present invention. Figure 4B It is a perspective view of the first sputtering device 400 according to the present invention. The sputtering device 400 includes: a stage 401 for mounting a substrate 404; and a cathode 402 for supporting a target 403, wherein the target support surface of the cathode 402 and the substrate support surface of the stage 401 are configured to Face each other. The stage 401 and the cathode 402 are respectively provided with a rotation axis A and a rotation axis B, and the stage 401 and the cathode 402 are configured to be rotatable at any angle around the rotation axis A and the rotation axis B, respectively. For example, a rotating member such as a motor may be used to rotate the stage 401 and the cathode 402, and the above-mentioned rotating member may be controlled by a control device. The rotation axis A and the rotation axis B are arranged to be parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com