Coke breeze cooling jacket device

A technology of cooling jacket and powder coke, which is used in the cooling of coke, coke oven, petroleum industry, etc., can solve the problem of rapid cooling of high temperature coke powder particles, and achieve the effect of uniform spacing, safe operation and increased cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

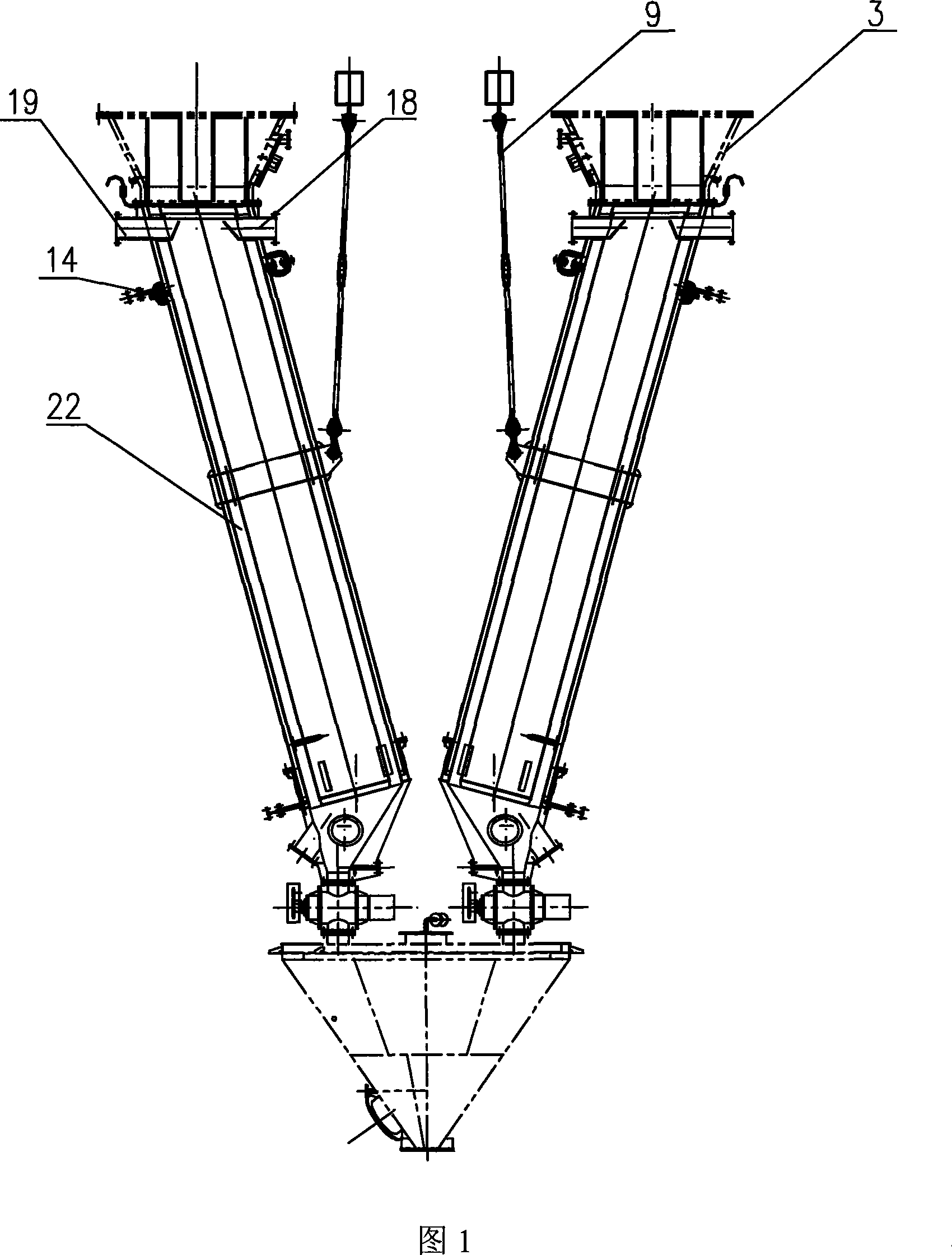

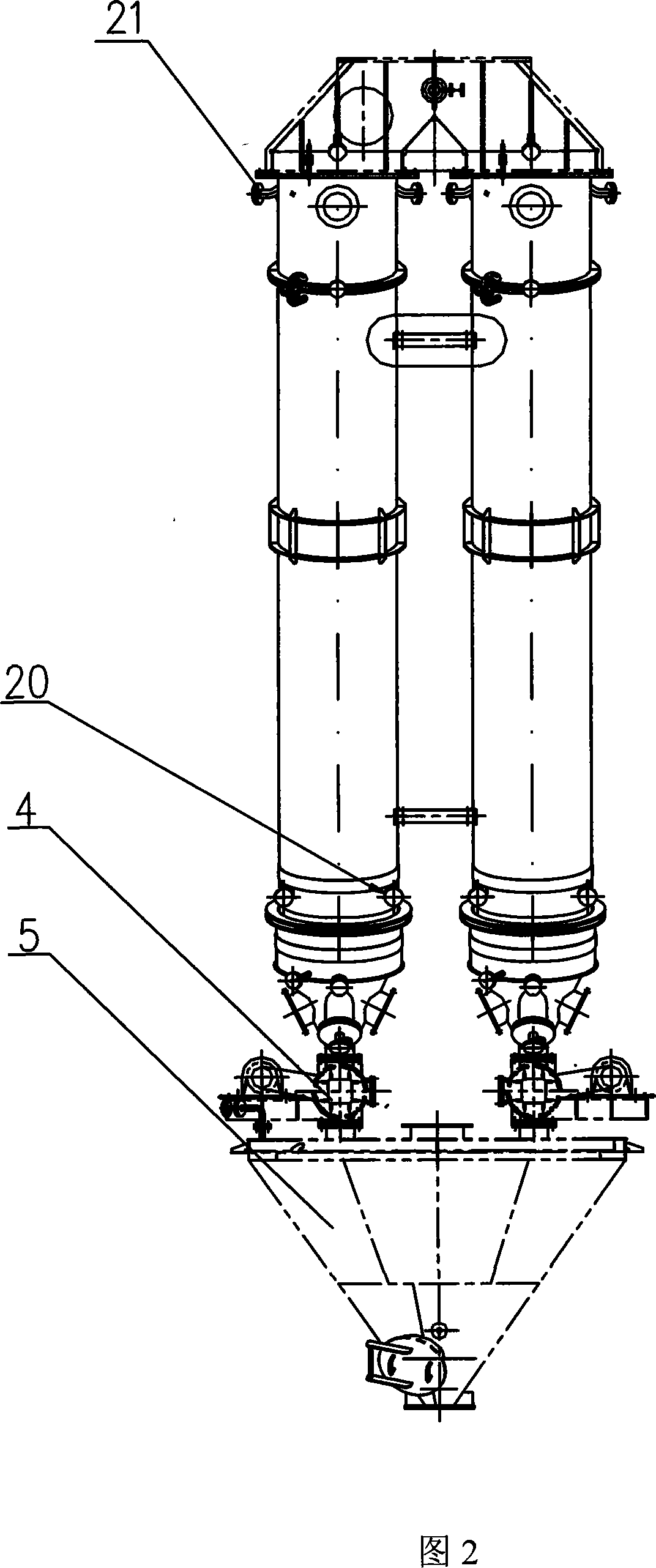

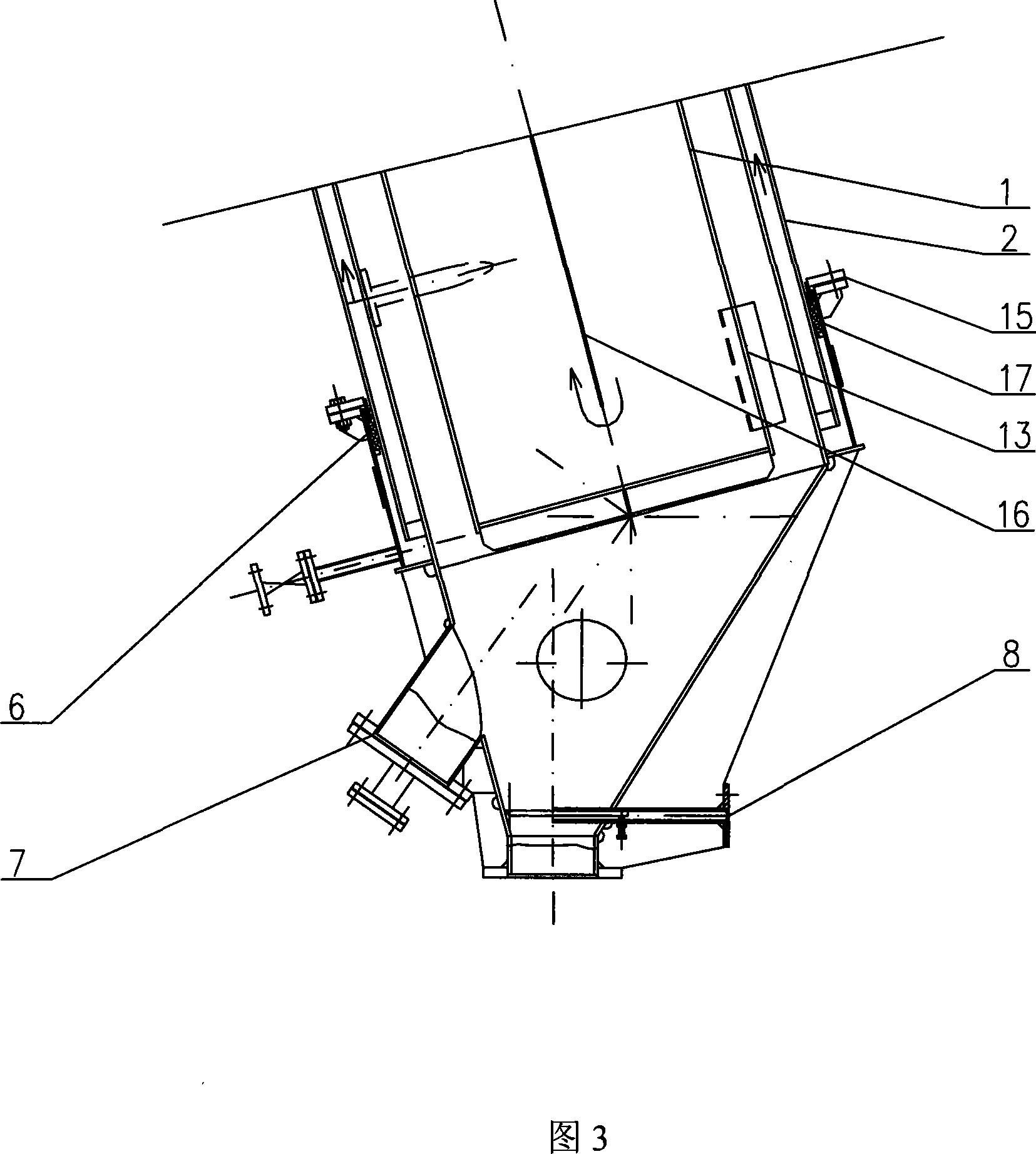

[0018] The powder coke cooling jacket device will be described in detail below in conjunction with the accompanying drawings. See Figure 1, Figure 2, Figure 3, Figure 4, and Figure 5.

[0019] A powder coke cooling sleeve device, comprising an inner sleeve 1, an outer sleeve 2, an upper connection flange 14, a lower connection flange 15, a packing gland sealing structure 6, an inner cylinder water supply port 18, and an inner cylinder drain port 19 , the water supply port 20 of the outer cylinder, the drain outlet 21 of the outer cylinder, the inner sleeve 1 is a tubular sleeve, and the two parts are separated by a partition plate 16 in the middle, and the bottoms of the separated two parts are connected; the outer sleeve 2 is a ring-shaped double The layer of circular tubes is set outside the inner sleeve, and the channel between the inner wall of the outer sleeve 2 and the outer wall of the inner sleeve 1 is the coke powder channel 22; for the convenience of installation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com