Pyrococcus produced high temperature alpha-glucosidase and enzyme producing method thereof

A technology of glucosidase and high temperature, applied in the field of microbial engineering, can solve the problems of few research reports on the properties and applications of α-glucosidase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

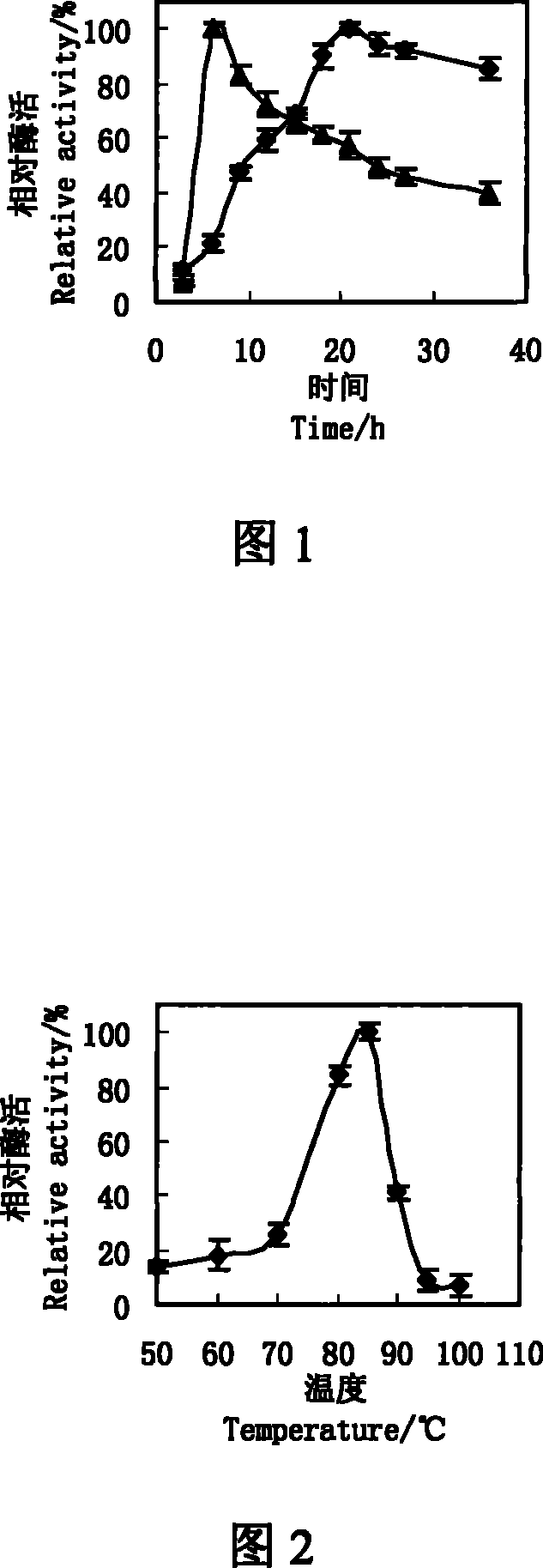

[0059] Example 1. A kind of thermococcus (Thermococcus sp.HJ21) produces the method for high-temperature α-glucosidase, and its steps are as follows:

[0060] (1) The seed solution is inoculated on the enzyme-producing medium with an inoculation amount of 2.5%, and cultured at 85° C. for 21 hours. The culture solution is filtered with filter paper to remove sulfur particles, and centrifuged at 10,000 r / min for 10 minutes to remove the bacteria. supernatant;

[0061] (2) Add ammonium sulfate to the supernatant to 65% saturation, overnight at 4°C; centrifuge at 10000r / min for 30min, discard the supernatant, dissolve the precipitate with 25mM pH7.5 Tris-HCl solution, dialyze overnight at 4°C, Centrifuge at 12000r / min for 10min, and the obtained supernatant is high-temperature α-glucosidase.

Embodiment 2

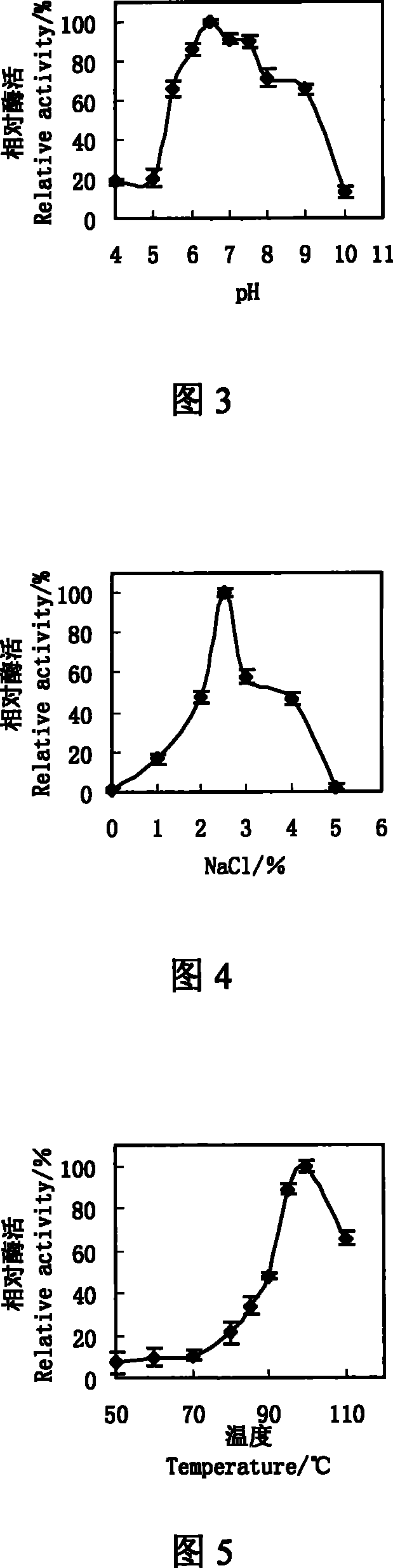

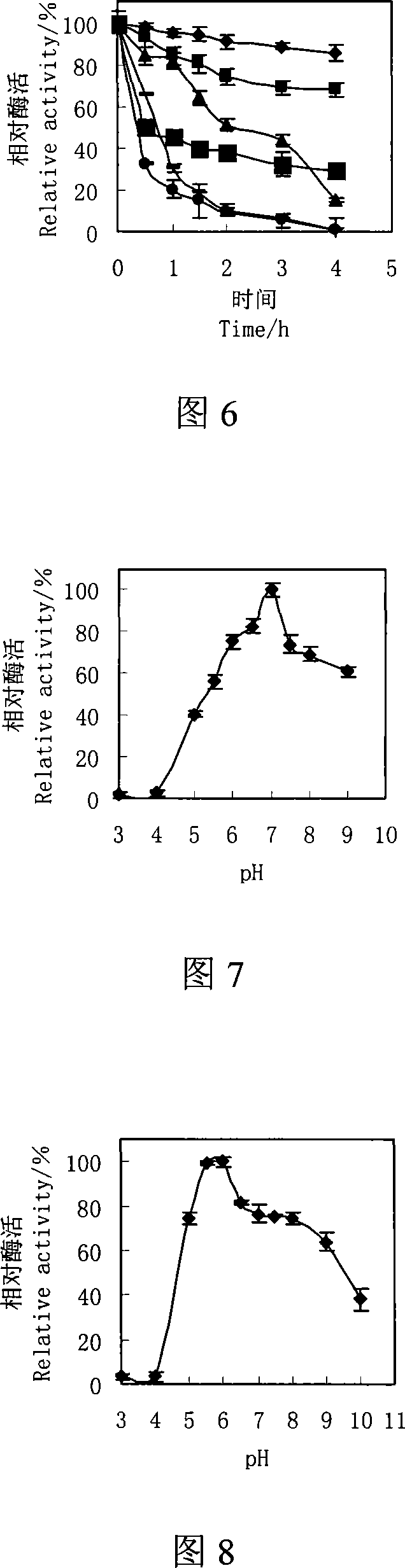

[0062] Example 2. A high-temperature α-glucosidase produced by the method described in Example 1, the enzymatic properties of the high-temperature α-glucosidase are: the optimum temperature for the enzyme action is 100°C, and there is still 60% enzyme activity; keep 90% of enzyme activity at 80°C for 4 hours, keep 80% of enzyme activity at 90°C for 1 hour; Ca 2+ It can reduce the thermal stability of high-temperature α-glucosidase; the enzyme is suitable for pH 7.0, and the enzyme activity is more than 70% at pH 6.0-8.0; the enzyme is stable at pH 5.0-8.0; Fe 3+ 、K + 、Ag + , DTT and EDTA can activate the enzyme, Cu 2+ 、Al 3+ 、Ni 2+, iodoacetic acid and SDS can inhibit the enzyme; 1mM Hg 2+ Completely inhibits the activity of the enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com