Electrostatic operating apparatus

An electrostatic action and electrode technology, applied in the field of electrostatic action devices, can solve the problems of limiting the relative movement of the substrate, difficult to improve the kinetic energy and electric energy conversion efficiency, difficult to improve the power generation efficiency of the generator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

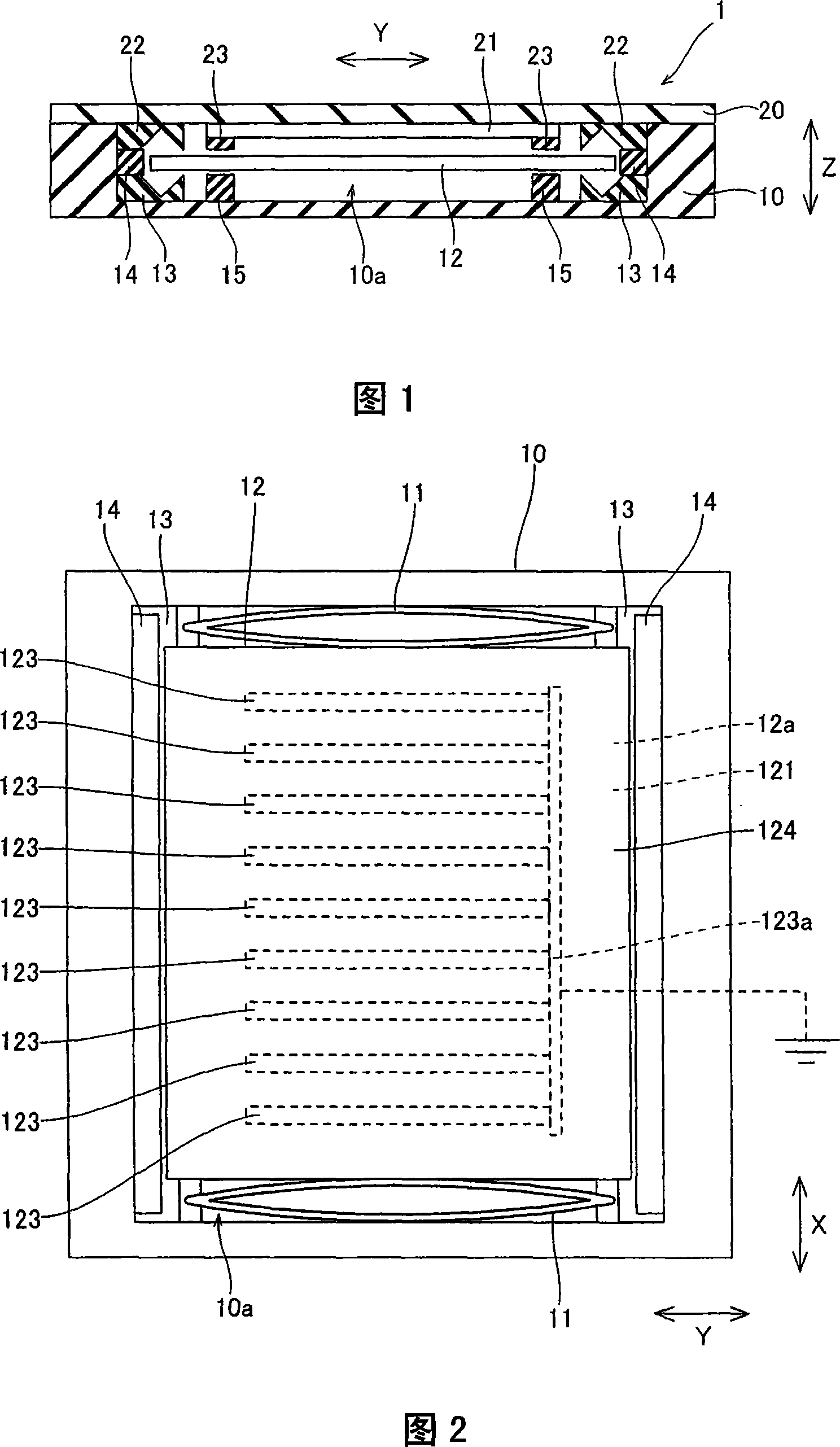

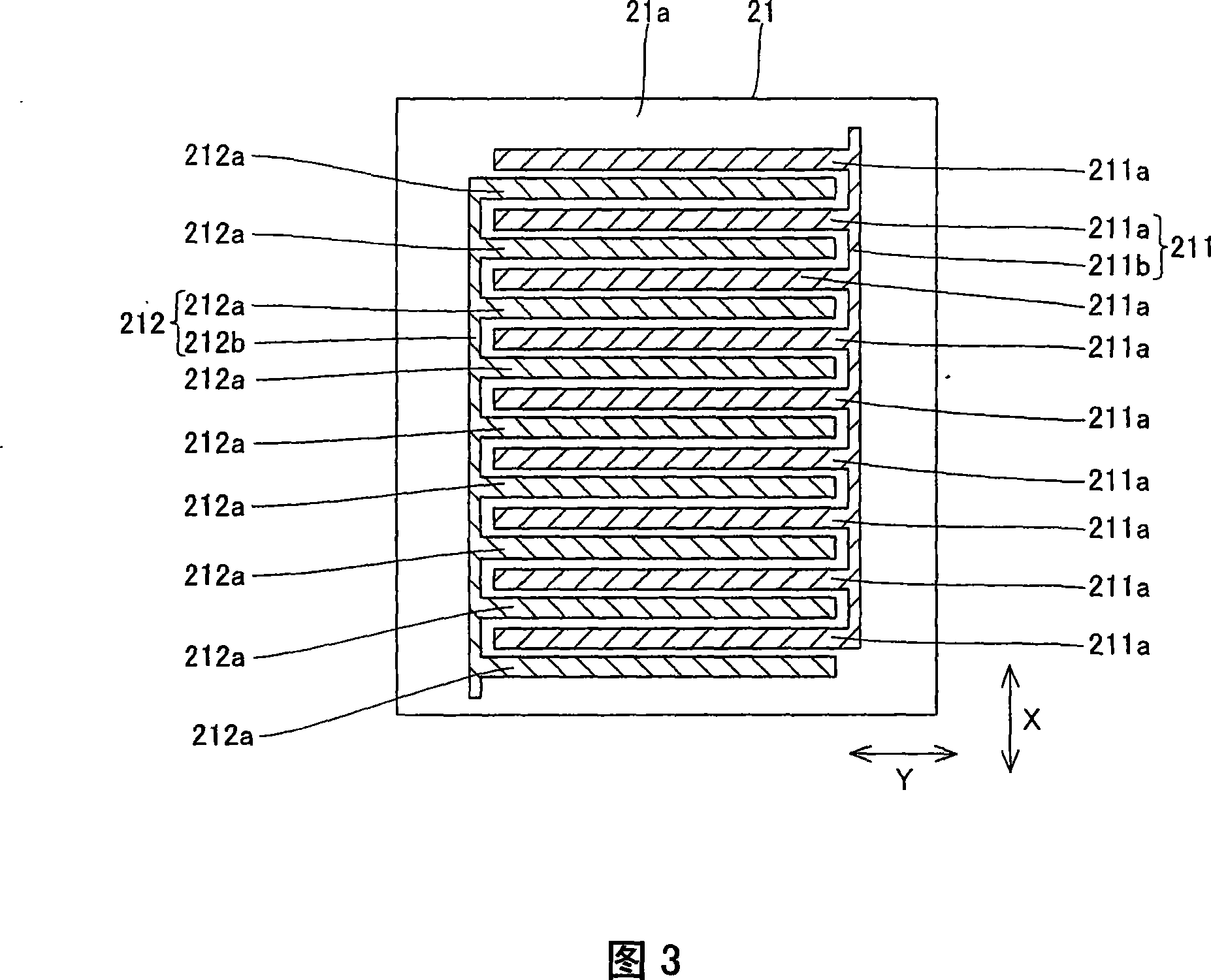

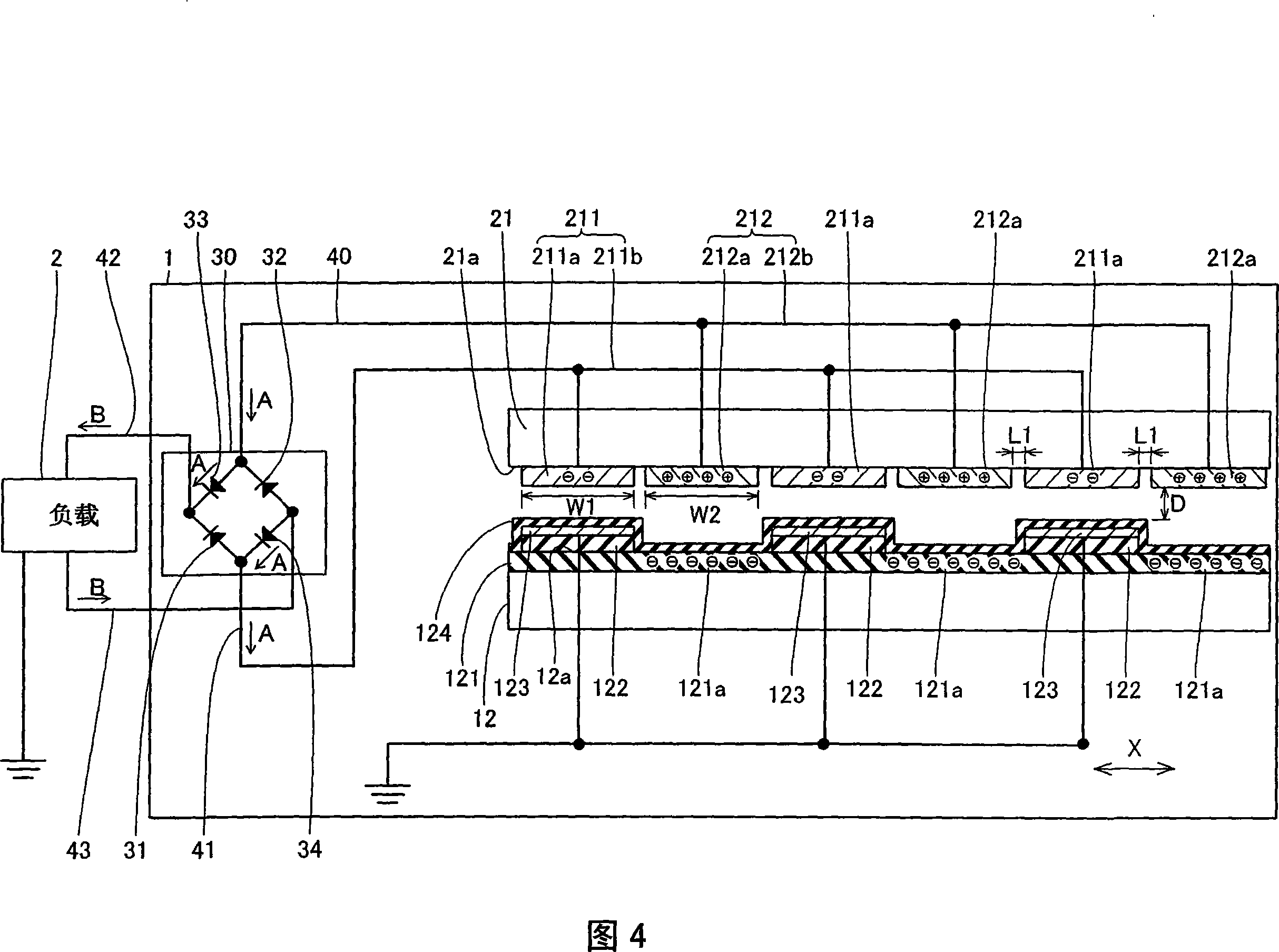

[0021] First, referring to FIGS. 1 to 5, the structure of the electrostatic induction type power generation device 1 in the first embodiment of the present invention will be described.

[0022] As shown in FIG. 1, the electrostatic induction type power generation device 1 in the first embodiment includes: a lower frame 10 formed with a receiving portion 10a; and an upper frame installed on the upper surface of the lower frame 10 to block the receiving portion 10a Body 20; and bridge rectifier circuit 30 (refer to Figure 4). A load 2 (refer to FIG. 4) driven by the electrostatic induction power generation device 1 is connected to the electrostatic induction power generation device 1.

[0023] In addition, as shown in FIGS. 1 and 2, the receiving portion 10a of the lower frame 10 of the electrostatic induction type power generation device 1 is provided with a pair of elastic members 11 (refer to FIG. 2); a movable substrate 12 made of glass or silicon The substrate and the like are ...

no. 2 approach

[0048]In the second embodiment, unlike the first embodiment described above, as shown in FIGS. 7 and 8, the electrode 311 formed in a comb shape on the main surface 310a of the movable substrate 310 and the shield electrode 313 (guard electrode) are formed. The structure of the electrostatic induction type power generation device 300 will be described.

[0049] In the electrostatic induction type power generation device 300 of the second embodiment, as shown in FIGS. 7 and 8, an electrode 311 is formed on the main surface 310a on the fixed substrate 21 side of the movable substrate 310 formed of glass or silicon substrate. It is formed of Al, Ti, etc., and has a comb shape in a plan view. In addition, the movable substrate 12 is an example of the "second substrate" of the present invention. The electrode 311 has: a plurality of electrode portions 311a formed to extend in the Y direction at predetermined intervals in the X direction; and one end portion connecting the plurality of ...

no. 3 approach

[0064] In the third embodiment, as shown in FIGS. 10 to 12, unlike the second embodiment in which the electret member 312 and the shield electrode portion 313a that accumulate negative charges are formed, the pair is placed on the main surface 360a of the movable substrate 360 The configuration of the electrostatic induction type power generation device 350 that forms the electret member 312 with negative charges and the electret member 362 with positive charges will be described.

[0065] In the electrostatic induction type power generation device 350 of the third embodiment, as shown in FIGS. 10 and 11, a movable substrate 360 formed of a glass or silicon substrate or the like on a main surface 360a on the fixed substrate 21 side is formed with combs. Shaped electrode 311. In addition, on the electrode portion 311a of the electrode 311, an electret member 312 that accumulates negative charges is formed in a region corresponding to the electrode portion 311a. In addition, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com