Dry process manufacture of pyrotechnical objects, resulting pyrotechnical objects

A process, pyrotechnic technology, applied in the direction of compressed gas generation, ignition device, explosive processing equipment, etc., can solve the problems of high investment cost, long drying step verification time, adverse impact on production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

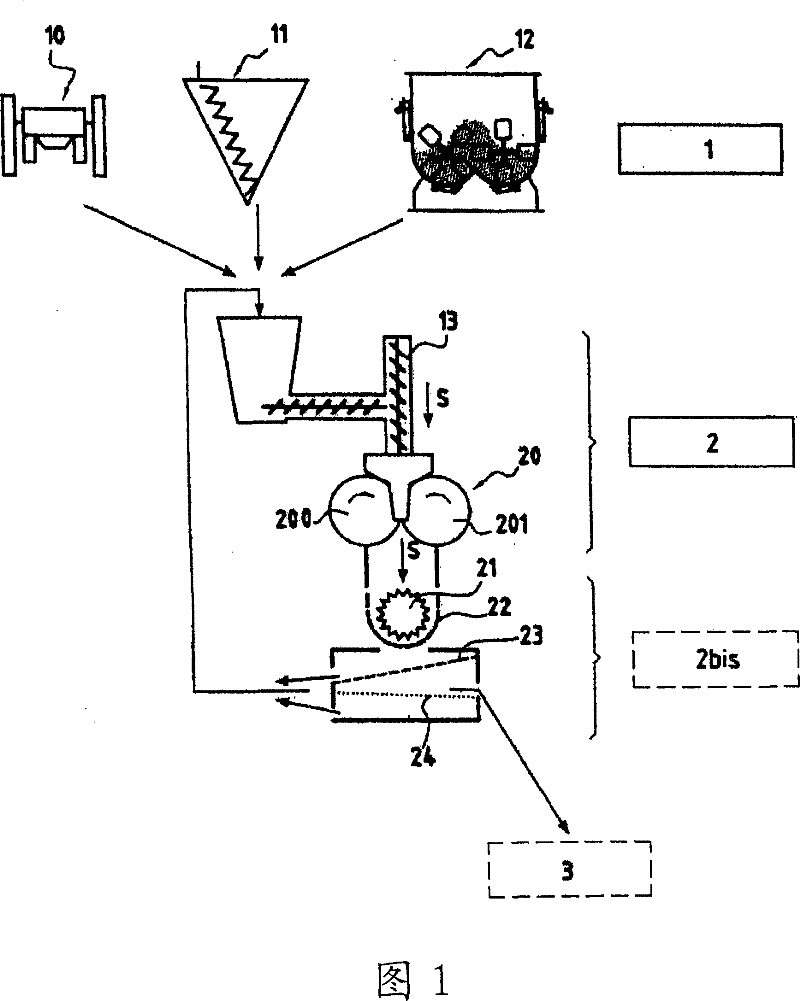

[0068] The manufacturing process according to the invention comprises a step 1 for mixing the raw materials forming the composition. Such as figure 1 As shown, mixing can be achieved using different equipment known in the state of the art. Said mixing can be achieved by means of a "rotator" 10 , a convective screw stirrer 11 , or a convective paddle stirrer 12 , for example. According to the invention, the ingredients are dry mixed.

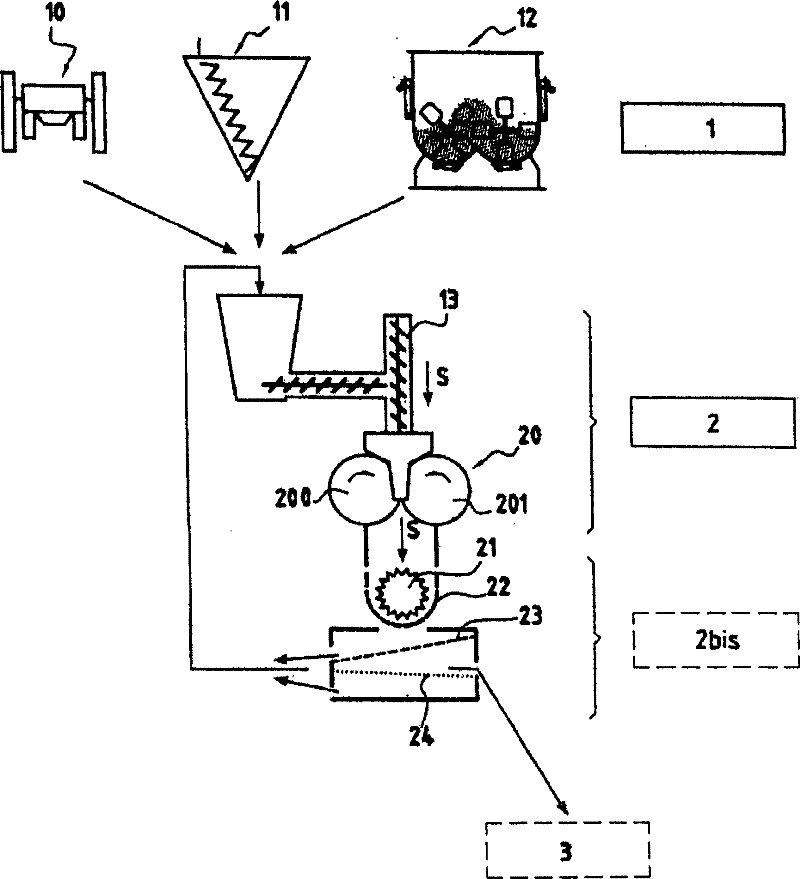

[0069] Next, the resulting mixture is subjected to a compaction step 2 and optionally a granulation step 2bis. According to the invention, this granulation step is achieved by a dry process, ie without the use of solvents. The mixture in powder form is first sprayed into a compactor 20 for a compaction step. Ejection of the material in the forward direction S is achieved, for example, using a screw system 13 open in the compactor 20 . The compactor 20 is in the form of two rollers 200, 201 arranged in parallel and spaced apart leaving a gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com