Lifting apparatus

A conversion device, assembly and disassembly technology, applied in the direction of lifting device, hoisting device, etc., can solve problems such as large operating force, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

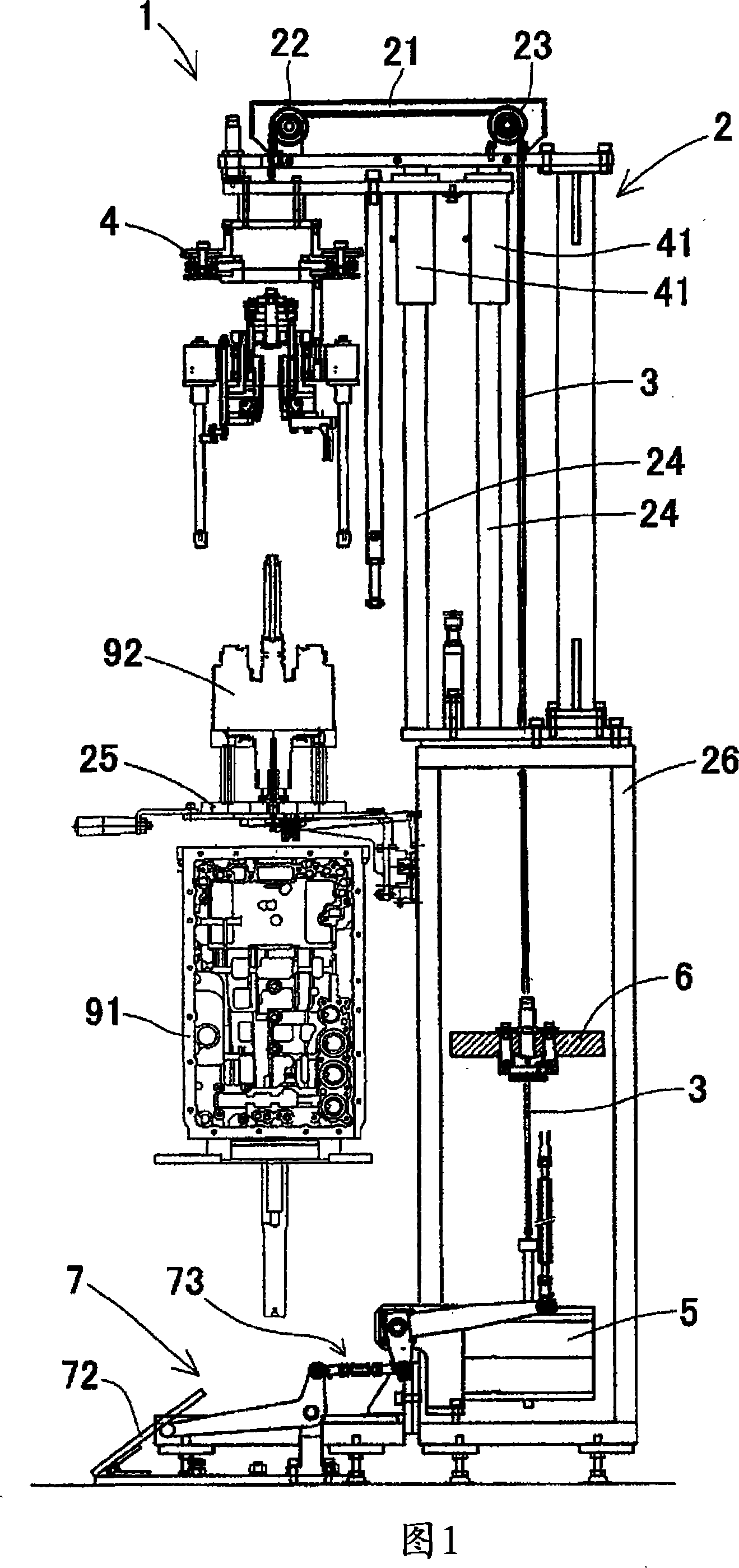

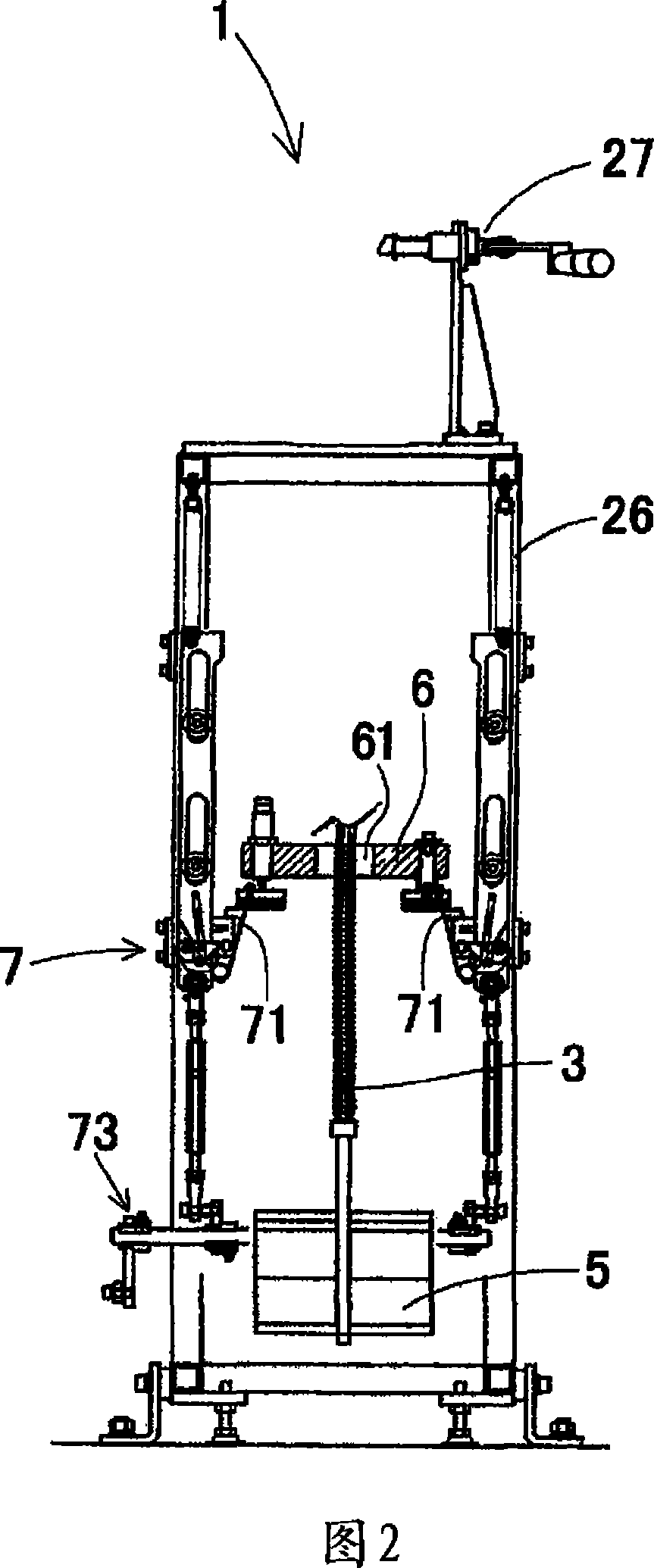

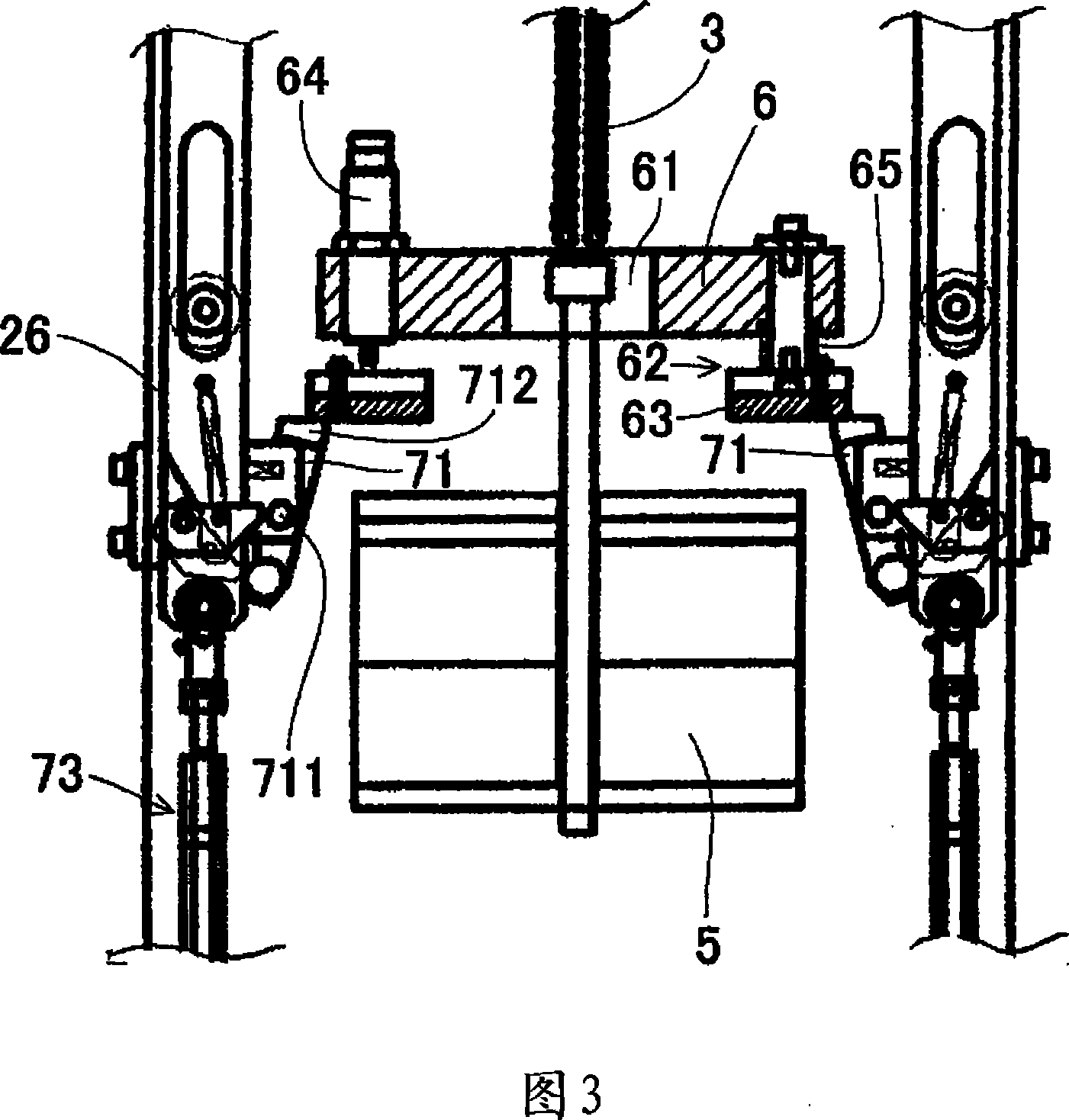

[0039] The best mode for carrying out the present invention will be described with reference to FIGS. 1 to 6 . FIG. 1 is a right side view illustrating a lifting device according to an embodiment of the present invention, and FIG. 2 is a partial rear view. The lifting device 1 of the embodiment is a device used in the process of assembling the mounting part 92 into the casing 91 of the automatic transmission, and the operator is located on the left side of FIG. 1 and works facing the right. The assembly device 1 of the embodiment is composed of a main body stand 2 , a chain 3 , an assembly jig 4 , a basic hammer 5 , an additional hammer 6 , and a hammer retreat preventing device 7 .

[0040] The main body stand 2 is a substantially columnar member vertically installed on the ground. On the top of the main body platform 2, a gear mounting part 21 is horizontally erected; at both ends of the gear mounting part 21, free-rotating support gears 22, 23 are pivotally supported. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com