Method for cleaning mine sump deposit and sump silt cleaner

A cleaning method and sediment technology, applied in drainage, mining equipment, earthwork drilling, etc., can solve the problems of large amount of pipeline layout, many equipment, easy damage of slurry suction pump, etc., and achieve simple and convenient operation and maintenance, manufacturing and The maintenance cost is suitable and the efficiency is significantly improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

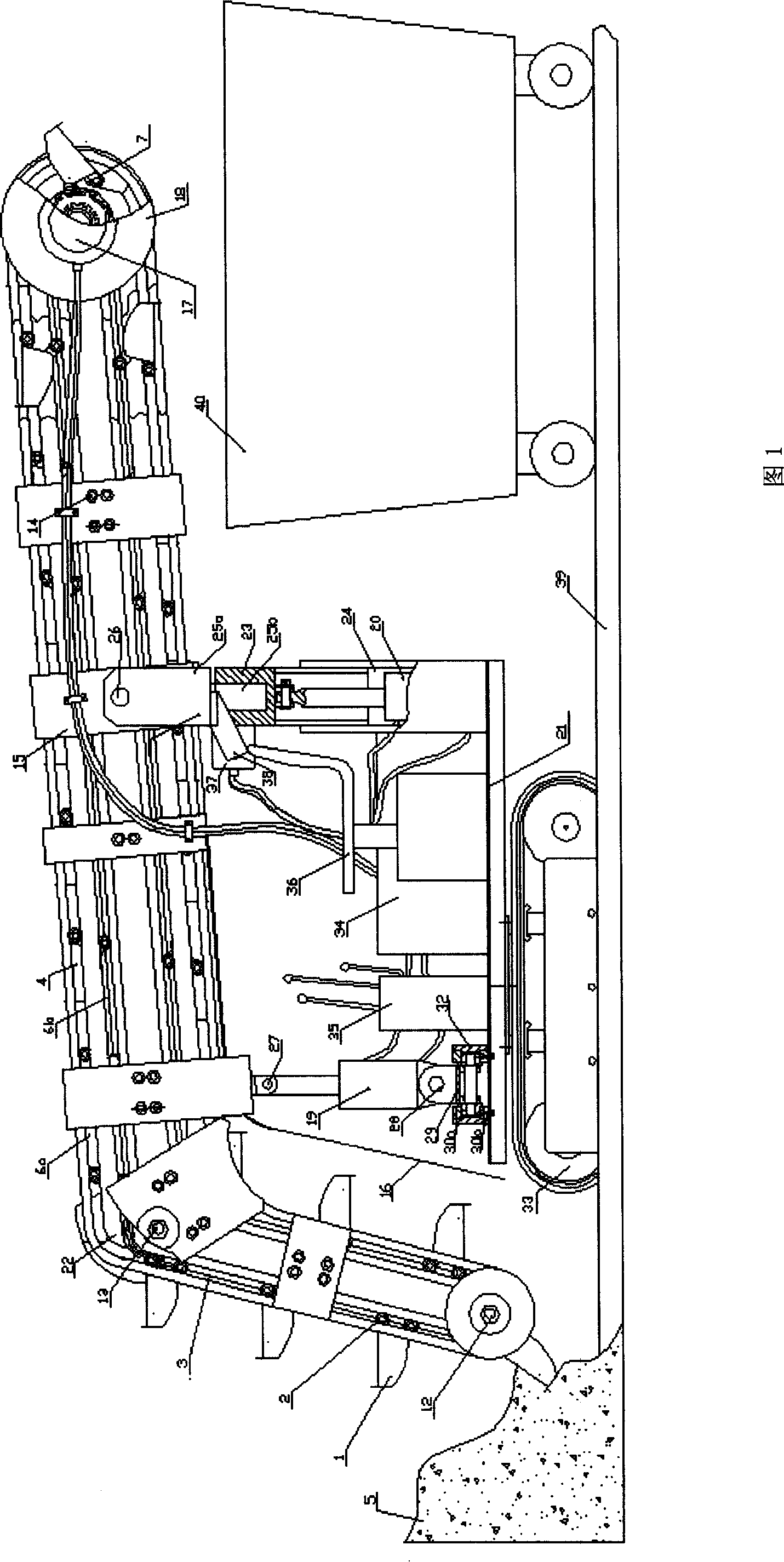

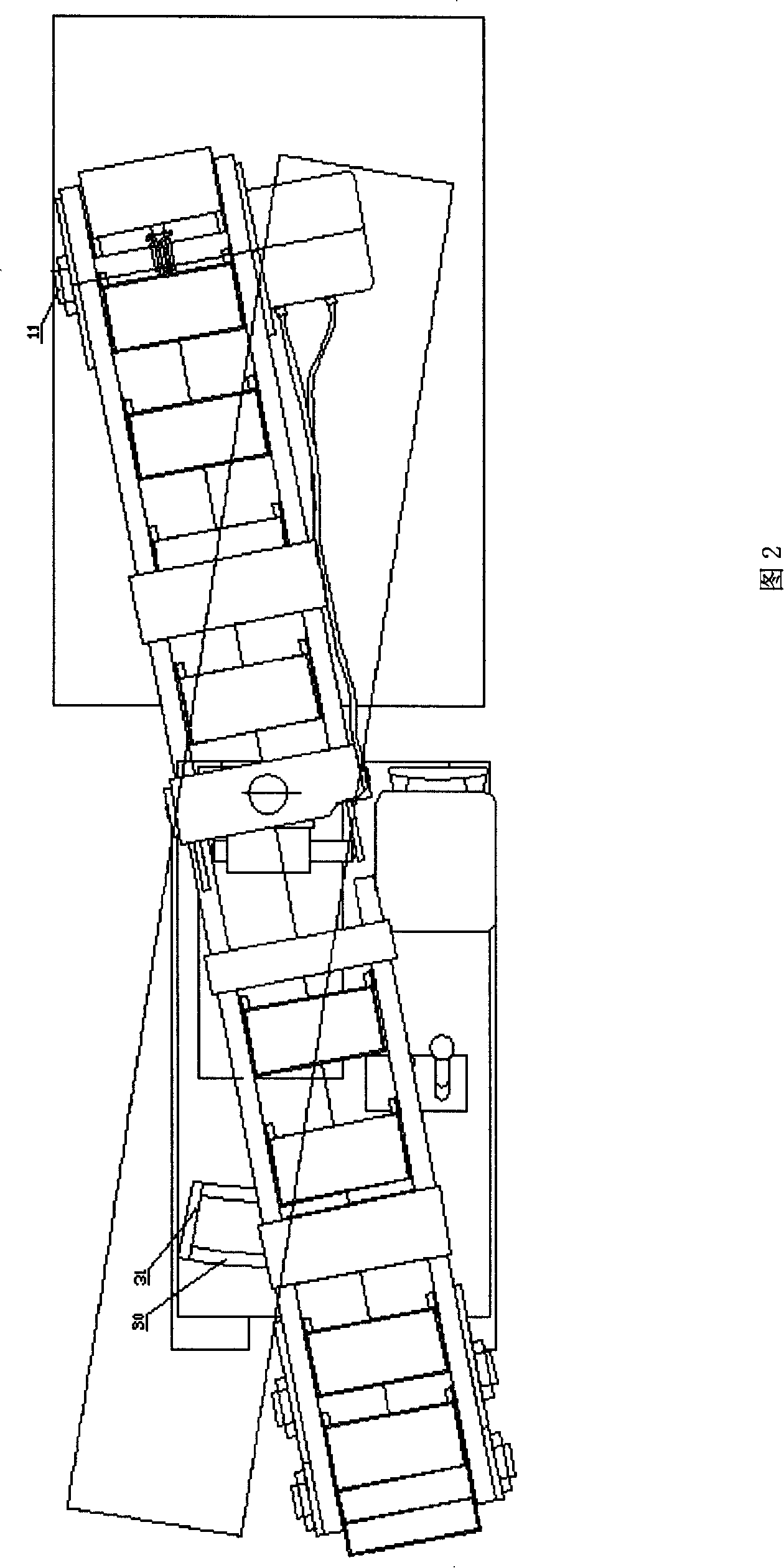

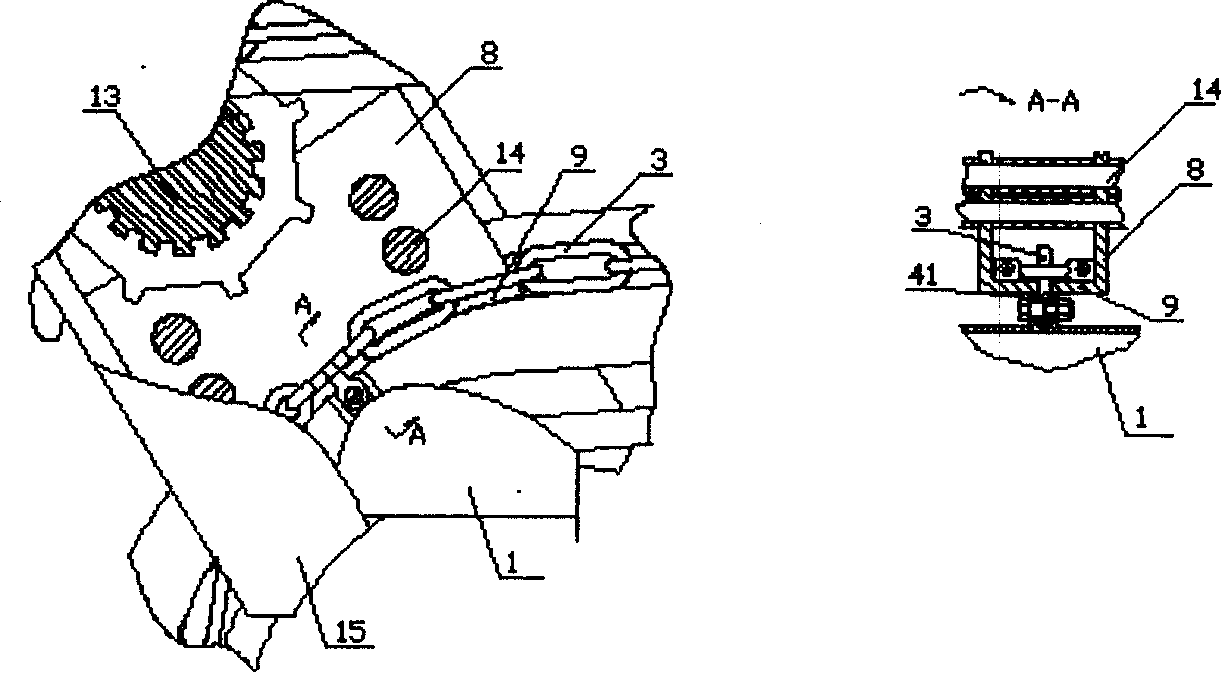

[0010] Below in conjunction with accompanying drawing, concrete implementation process of the present invention is described in further detail: this water bin desilting machine is designed with running gear (33), and platen (21) is fixed on the chassis of running gear (33), on the platen (21) The hopper rail frame (4) with double-sided synchronous circulation track is supported and installed, and the hopper rail frame is designed as a bent shape consisting of a vertical section and a horizontal section. The supporting connectors between the rails on both sides of the hopper rail frame (4) include the driving sprocket shaft (11) installed at the tail of the rail frame, the driven sprocket shaft (12) installed at the front end of the rail frame, and the intermediate driven sprocket shaft (13 ), also design necessary support bar (14), and the plate frame (15) that welds is arranged on the outer periphery of rail frame, they guarantee that rail frame has enough rigidity jointly. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap