Alcohol water-soluble resin and method for making same

A water-soluble resin and hydrophilic technology, which can be used in pharmaceutical formulations, organic active ingredients, monocarboxylate copolymer adhesives, etc., can solve problems such as cost increase and environmental pollution, and achieve the effect of reducing solvent costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

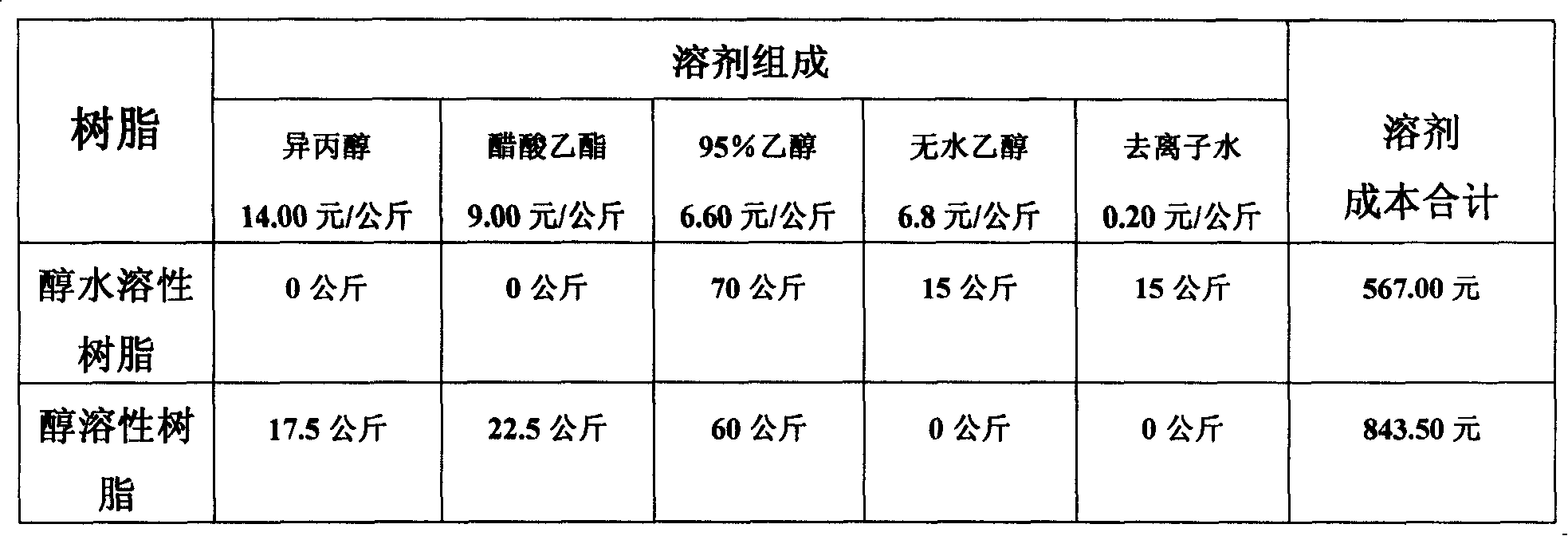

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 alcohol water-soluble resin of the present invention

[0032] Equipment: The equipment required by the present invention is: a reaction kettle equipped with a stirrer, a reflux condenser, a stainless steel dropping tank, a heating and a temperature controller.

[0033] ①. Add 20 kg of vinyl acetate and 5 kg of ethyl acrylate as component A, and add 10 kg of absolute ethanol as a diluent into the reaction kettle together, heat up and stir.

[0034] ②. 45 kg of vinyl acetate, 2.5 kg of ethyl acrylate, 2.5 kg of methyl acrylate, 4 kg of methyl methacrylate, 5 kg of acrylic acid, 10 kg of acrylamide, 6 kg of hydroxypropyl acrylate, azobisisobutyronitrile 0.9 kg is added to the drop-adding tank as component B. When the temperature of the material in the kettle rises to the reflux temperature, drop it into the kettle within 5 hours.

[0035] ③. Add 70 kg of 95% industrial alcohol and 20 kg of deionized water to the kettle after 2 hours of hea...

Embodiment 2

[0037] Embodiment 2 The preparation of alcohol water-soluble resin of the present invention

[0038] Weigh raw materials according to the following ratio:

[0039] A component: vinyl acetate 25 kg

[0040] Methyl acrylate 1 kg

[0041] Methyl methacrylate 7 kg

[0042] Add 15 kg of absolute ethanol as diluent

[0043] B component: vinyl acetate 35 kg

[0044] Methyl acrylate 2 kg

[0045] Methyl methacrylate 8 kg

[0046] Acrylic 3 kg

[0047] Hydroxypropyl Acrylate 15kg

[0048] Acrylamide 4 kg

[0049] Benzoyl Peroxide 0.6kg

[0050] Prepare 15 kilograms of deionized water and 75 kilograms of 95% denatured alcohol as diluents in addition, and the preparation method is the same as in Example 1 to obtain 200.7 kilograms of resin with a solid content of 50%.

[0051] The resin prepared by the formula described in Example 2 is most suitable for producing heat-resistant, retort-resistant intaglio plastic composite ink.

Embodiment 3

[0052] Embodiment 3 The preparation of alcohol water-soluble resin of the present invention

[0053] Weigh raw materials according to the following ratio:

[0054] A component: vinyl acetate 15 kg

[0055] Methyl acrylate 5 kg

[0056] Add 10 kg of absolute ethanol and 2 kg of deionized water as diluents

[0057] B component: vinyl acetate 50 kg

[0058] Methyl acrylate 10 kg

[0059] Acrylic 2 kg

[0060] Acrylamide 10 kg

[0061] Hydroxyethyl Acrylate 8 kg

[0062] Azobisisobutyronitrile 0.8 kg

[0063] In addition, 18 kilograms of deionized water and 70 kilograms of 95% technical alcohol were used as diluents, and the preparation method was the same as in Example 1 to obtain 200.7 kilograms of resin with a solid content of 50%.

[0064] The resin prepared by the formula described in Example 3 is suitable for producing common gravure plastic composite ink.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap