Four-piston cylinder engine

A technology of rotating engines and piston cylinders, applied to internal combustion piston engines, reciprocating piston engines, engines with rotating cylinders, etc., can solve the problems of high manufacturing precision of piston triangles, insufficient combustion, narrow and long combustion chambers, etc., and achieve structural Compact, low vibration and noise, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

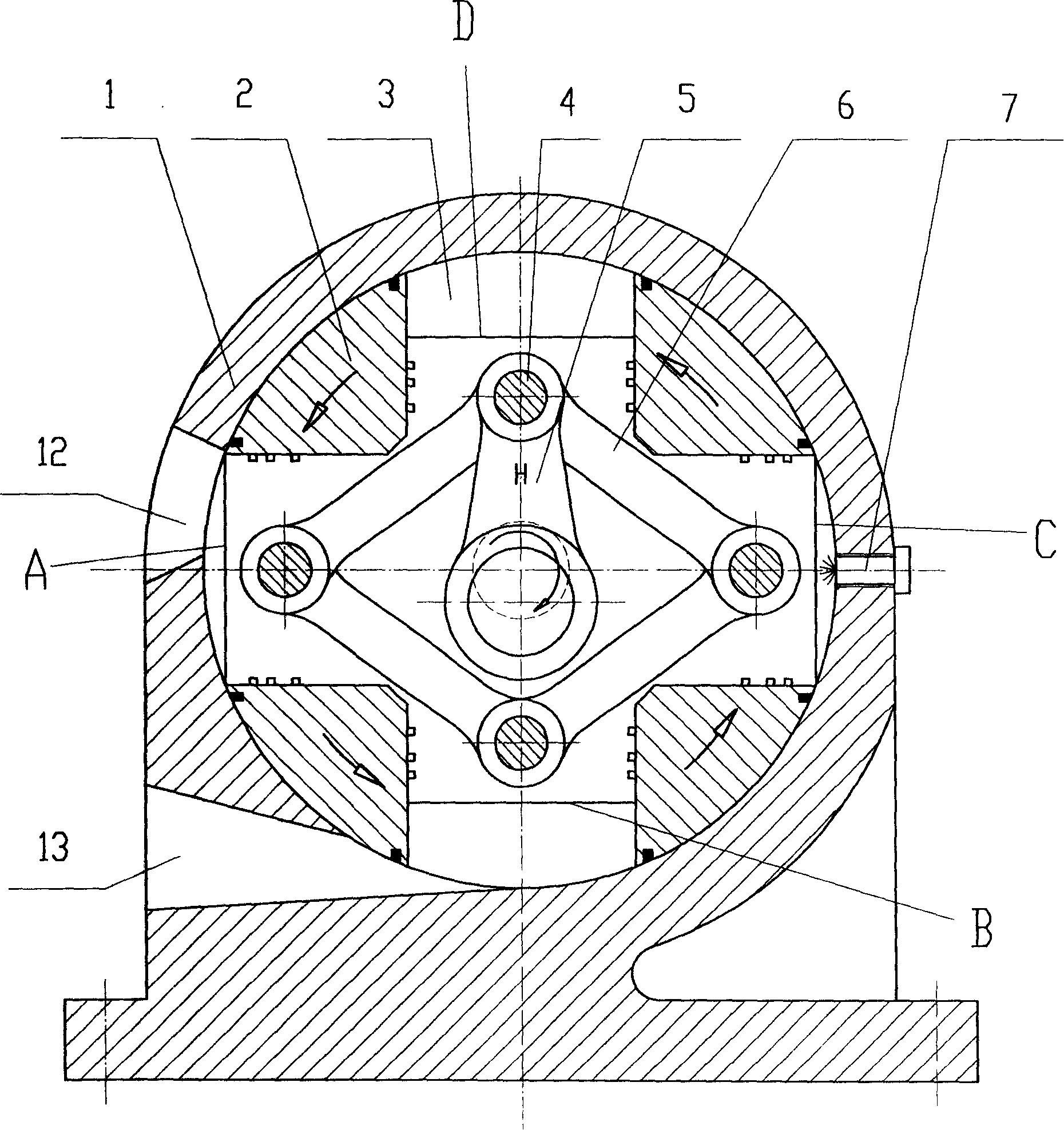

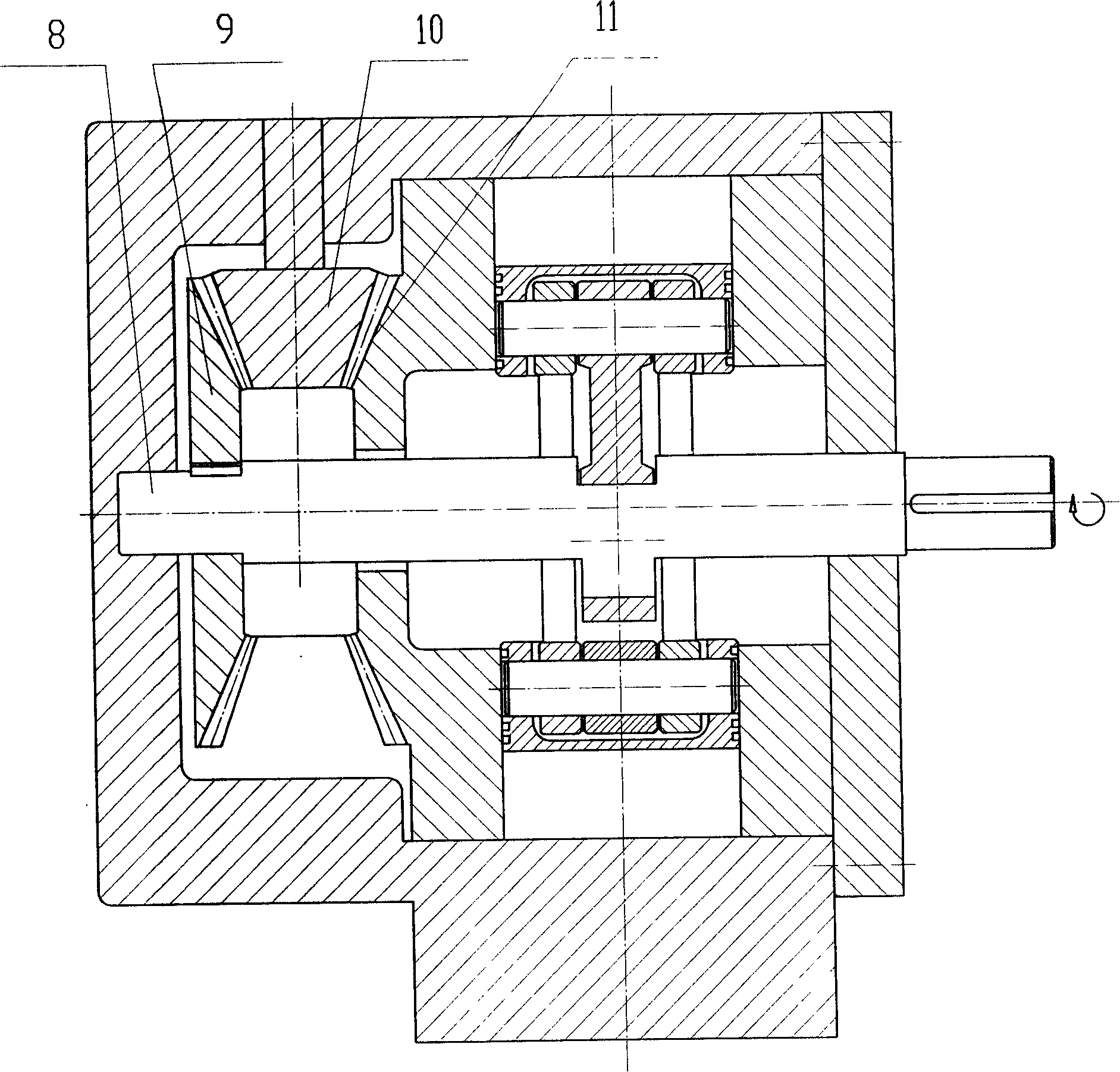

[0024] Such as figure 1 , figure 2 As shown, it is a preferred embodiment of the present invention. A rotor-type cylinder 2 is sleeved in the housing 1, and four cylinders 3 are arranged orthogonally on the top of the rotor-type cylinder 2. Each cylinder 3 A piston A, B, C, D is provided, and a good cooperation is maintained between each piston and the cylinder body 2 . A linkage rod 6 is pivotally arranged between every two adjacent pistons A, B, C, D, and the four linkage rods 6 are of equal length. A piston D is pivotally connected to the linkage rod 6 through the piston pin 4, and is also pivotally connected to a connecting rod 5, and the other end of the connecting rod 5 is pivotally connected to the crankshaft 8 of the engine. A driving gear 9 is also arranged on the crankshaft 8, and the driving gear 9 meshes with the idler gear 10 installed on the housing 1, and the idler gear 10 meshes with the driven gear formed on the cylinder block 2 at the same time. Gear 11 m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap