Triplet electro-heat execution valve and terra warm water mixing device

A technology of implementing valve and electric heating, applied in valve device, valve operation/release device, multi-port valve, etc., can solve the problems of slow flow adjustment, slow temperature control, high manufacturing cost, etc., to achieve good flow Control and mixing water temperature control, fast response, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (Example 1, three-way electrothermal actuator valve)

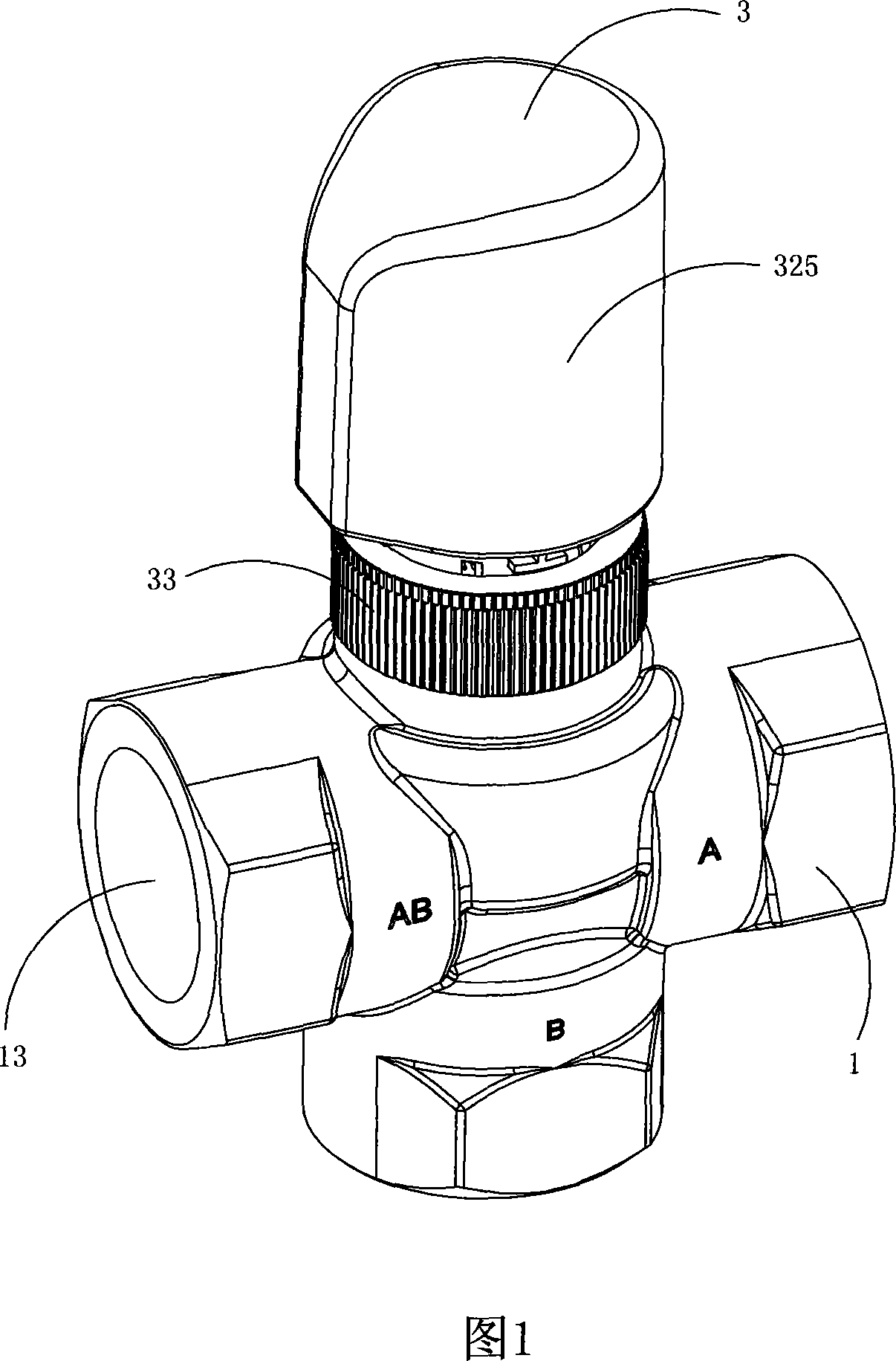

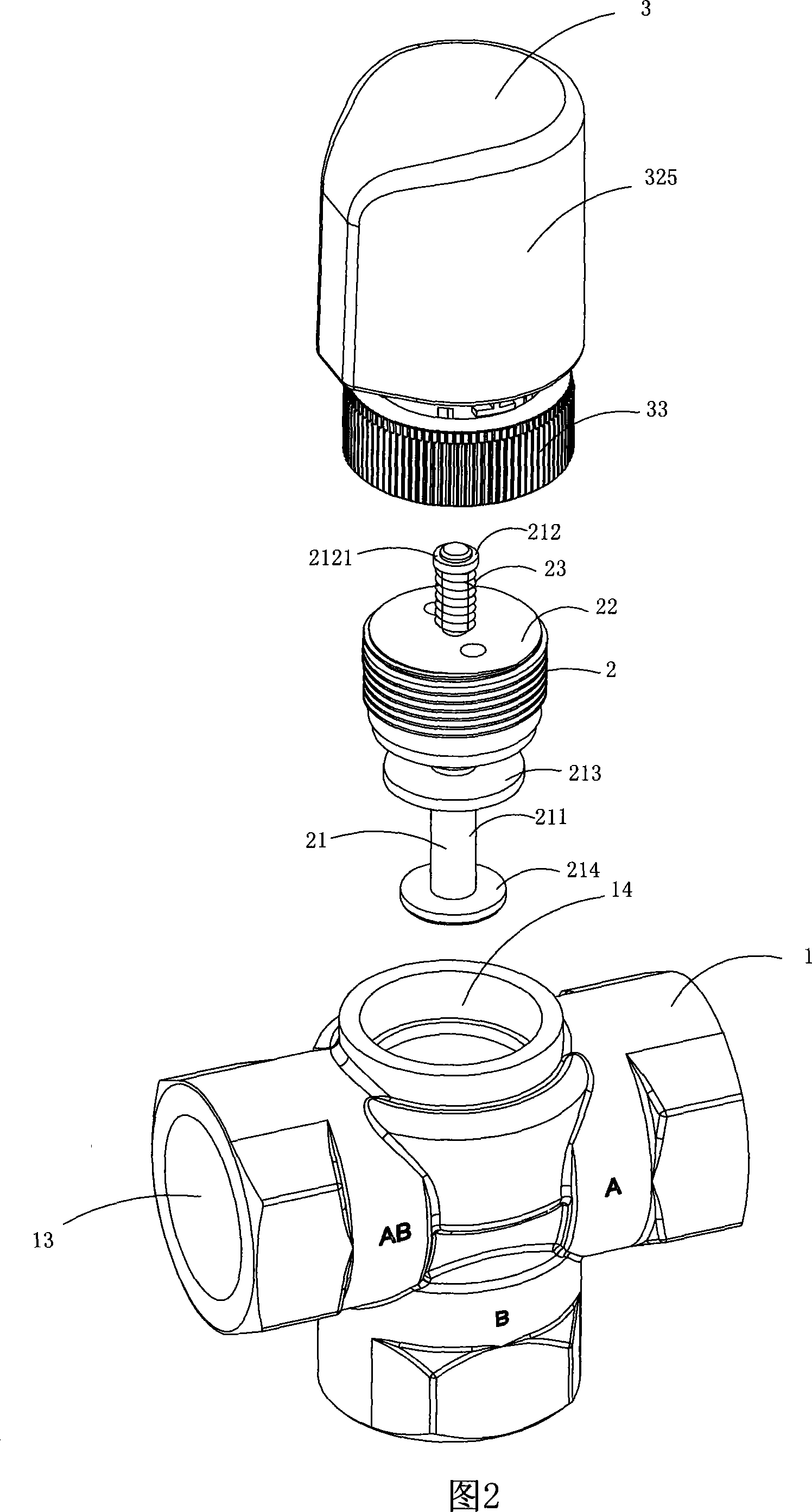

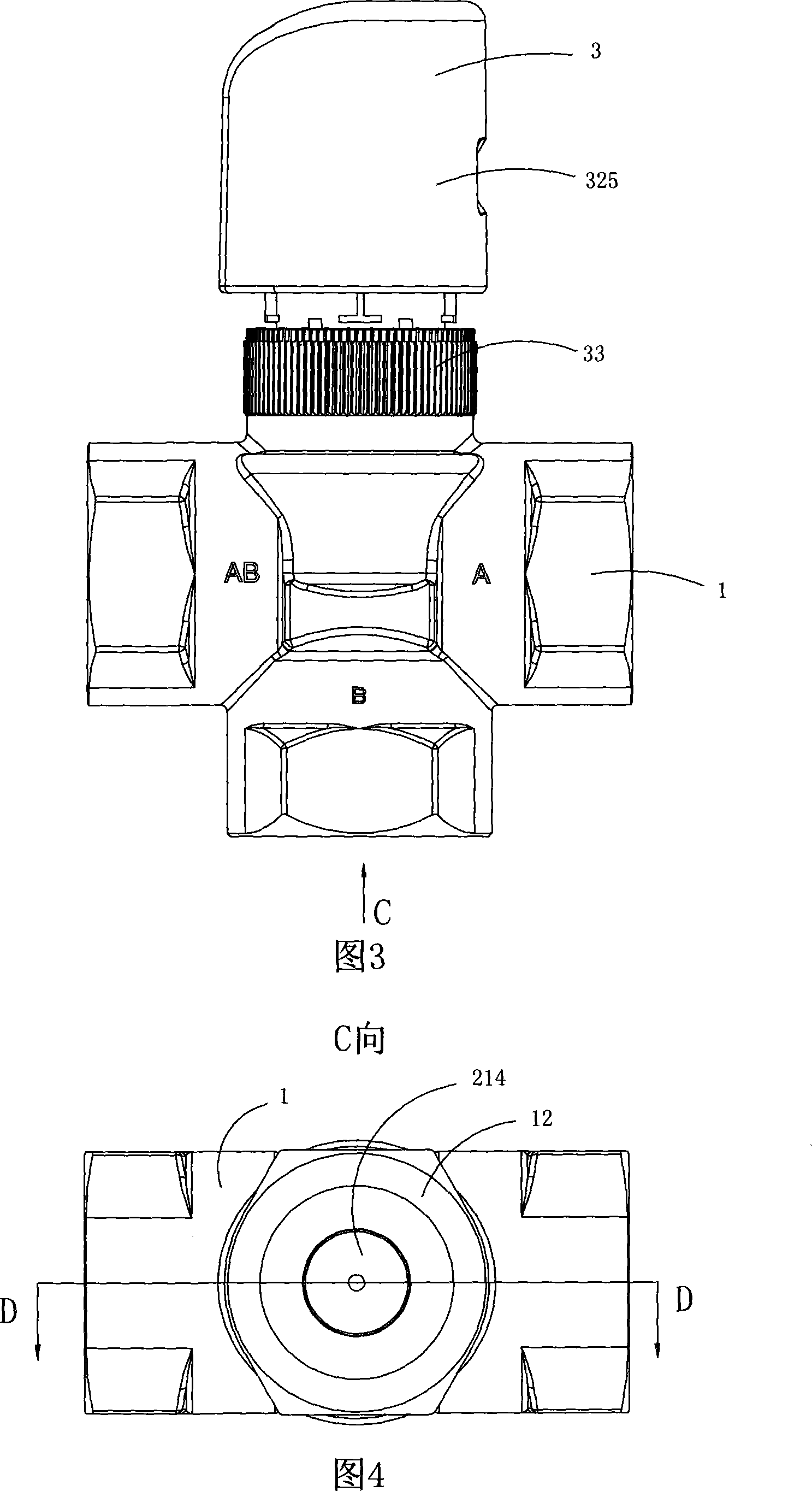

[0046] Figures 1 to 18 show specific implementations of the three-way electrothermal actuator valve of the present invention. Fig. 1 is a schematic diagram of a three-dimensional structure of the three-way electrothermal actuator valve of the present invention; Fig. 2 is an exploded schematic diagram of the three-way electrothermal actuator valve shown in Fig. 1; Fig. 3 is a front view of the three-way electrothermal actuator valve shown in Fig. 1 Schematic diagram of the structure; Fig. 4 is a C-direction view of the three-way electrothermal actuator valve shown in Fig. 3; Fig. 5 is a sectional view of the D-D line in Fig. 4; Fig. 6 is a three-dimensional structure of the valve body in the three-way electrothermal actuator valve shown in Fig. 1 Schematic diagram; Figure 7 is a schematic diagram of the three-dimensional structure of the valve body shown in Figure 6 viewed from another angle; Figure 8 is a schematic ...

Embodiment 2

[0055] (Embodiment 2, floor heating and water mixing device)

[0056] Fig. 19 is a schematic structural view of the floor heating water mixing device of the present invention, showing a specific implementation of the floor heating water mixing device of the present invention.

[0057] This embodiment is a ground heating water mixing device, as shown in Figure 19, including a water inlet pipe 4, a water separator 41 communicating with the water inlet pipe 4, a bypass pipe 5, a mixed water temperature measuring sensor 6, a thermostat 8, and a water outlet pipe 9. A three-way valve 91, a water collector 92 and a water pump 93 that are sequentially connected to the water outlet pipe 9; the three-way valve 91 is the three-way electric heating actuator valve 91 described in the first embodiment above; the water inlet of the water pump 93 and the water collector The water tank 92 is connected, the water inlet 11 of the three-way electric heating actuator valve 91 is connected with th...

Embodiment 3

[0061] (Embodiment 3, floor heating and water mixing device)

[0062] This embodiment is basically the same as Embodiment 2, except that the floor heating and water mixing device further includes a temperature sensor for measuring room temperature. Control the hot water intake according to the measured room temperature. For example, when the room temperature is high, the thermostat will issue an instruction to reduce the hot water intake by controlling the water intake of the water pump, which can meet the heating needs of users. , and save water; if the room temperature is low, the amount of hot water can be increased to heat up the room quickly to meet the needs of users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com