Fire resistant lighting fitting

A lamp and lamp installation technology, which is applied in fire rescue, lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of increasing cost, complexity of producing lamps, high temperature of lamps, etc., and achieves the effect of simplifying production and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, top, bottom, side and similar terms are used for convenience only, referring to the downlight and the intended orientation shown in the attached drawings, and shall not be taken as other limitations.

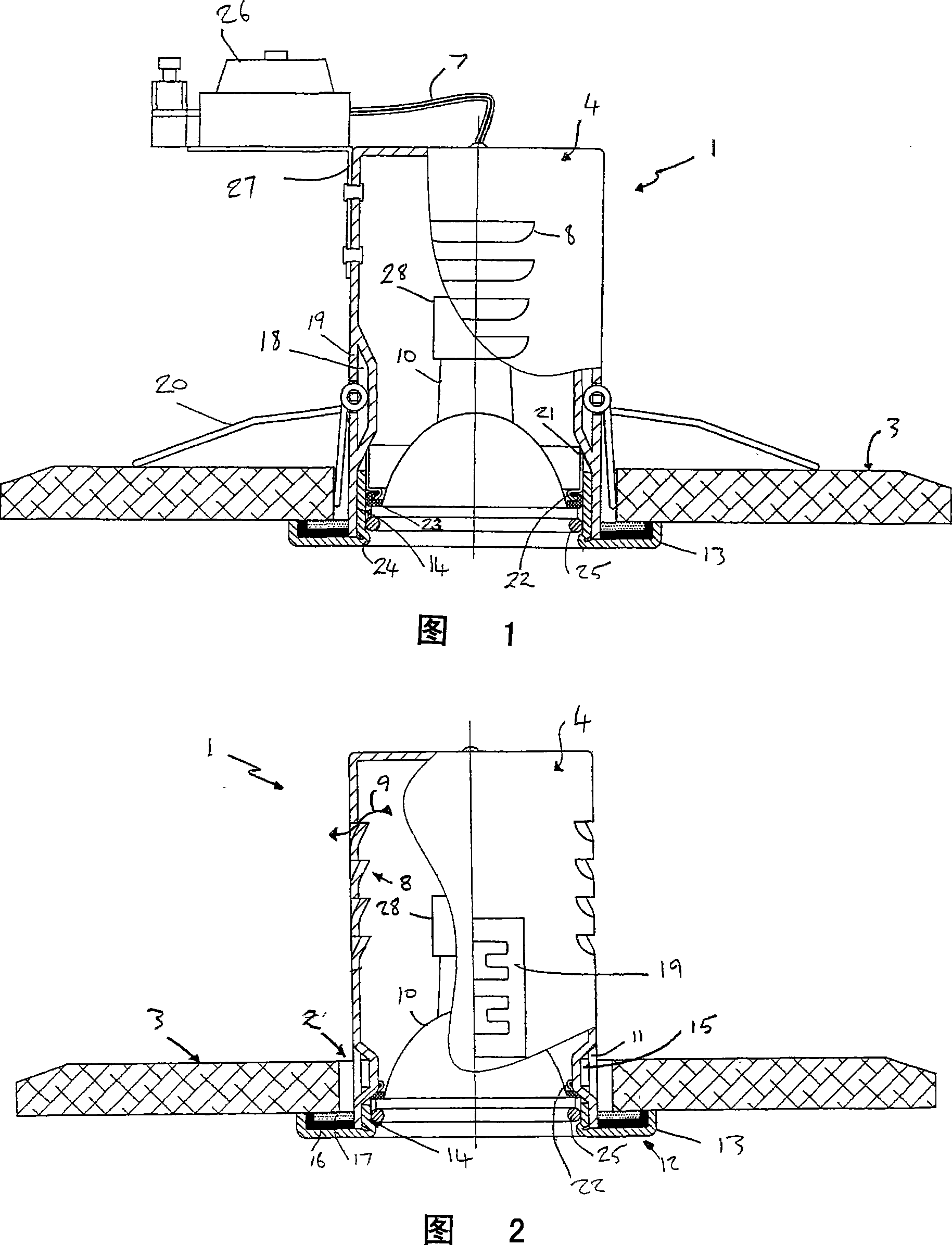

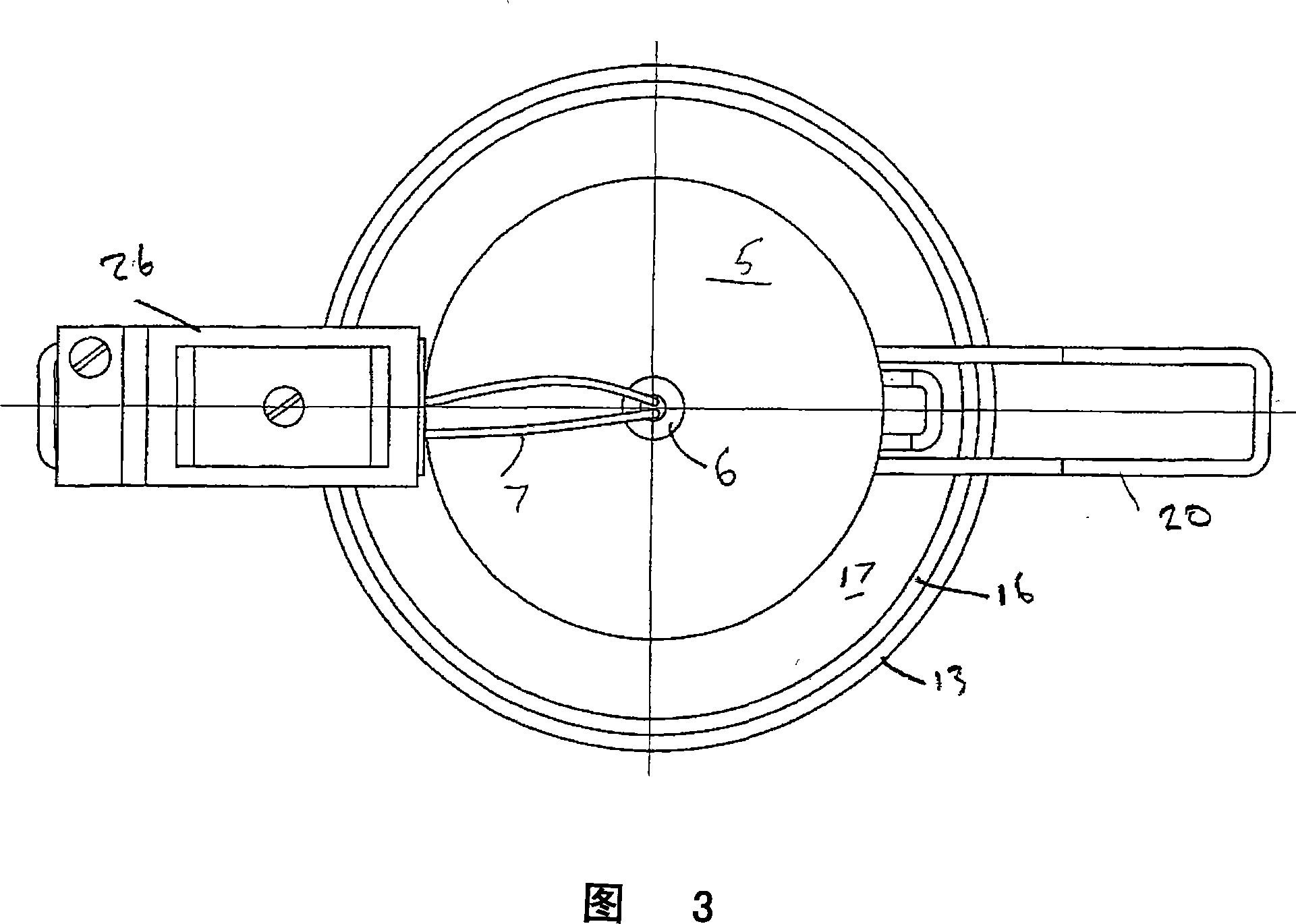

[0019] As shown in FIG. 1 , a downlight 1 is mounted in a hole 2 formed in a gypsum ceiling panel 3 .

[0020] The downlight 1 comprises a housing 4 made of 1 mm thick steel and powder coated. The cover body 4 has a substantially cylindrical side wall, the lower end is open (as shown in the figure), and the upper end is closed to form the top 5 of the downlight. A roughly circular hole with a diameter of about 5 mm is opened at or near the center of the top 5 of the cover body 4 . This hole can be used for a pair of insulated electric wires 7 to penetrate in the described cover body, and a plastic grommet 6 is housed on the hole, prevents that metal cover body 4 steely tops 5 form the cutting edge of hole damage electric wire 7. The size of the holes is as ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap