A reinforcement method for tunnel prefabricated steel arch frame

A technology for steel arches and tunnels, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of increasing construction difficulty and time, complex construction process, and long-term traffic impact, so as to reduce construction procedures and construction time , The effect of short sealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057]The present invention realizes rapid reinforcement of the operating tunnel by installing a prefabricated steel arch structure inside the tunnel lining, such as Figure 8 shown, including the following steps:

[0058] (1) Use 3D laser scanning to obtain the inner contour information of the reinforced section lining, and make steel arches accordingly; the steel arches are composed of prefabricated segmental components;

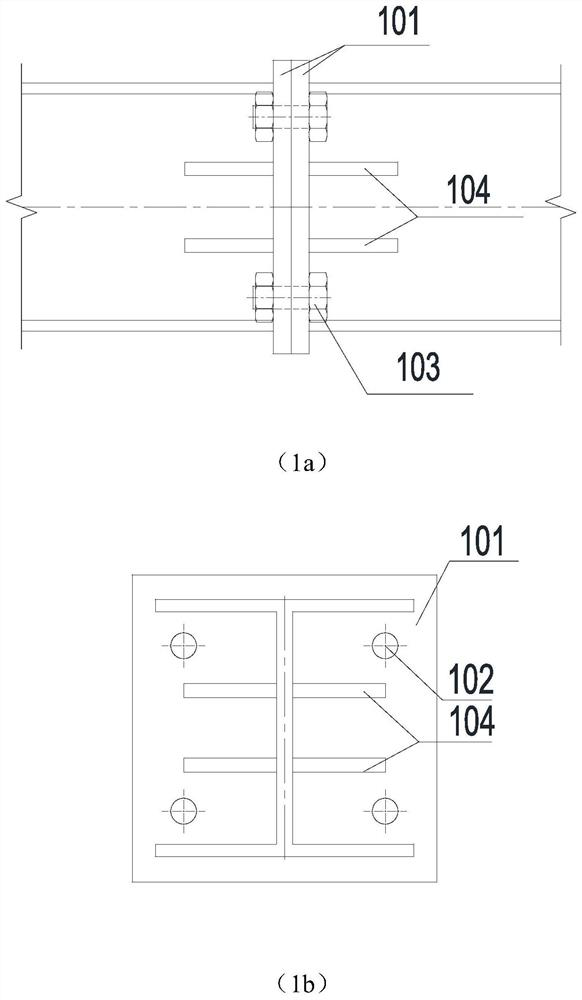

[0059] (2) On the inner side of the lining, from the foot of the side wall to the arch, along the ring direction, the prefabricated steel arch members are combined into a steel arch frame through bolts; if the lining is peeled off, install the metal mesh before installing the steel arch frame ; If the lining surface is uneven, remove the raised part before installing the steel arch.

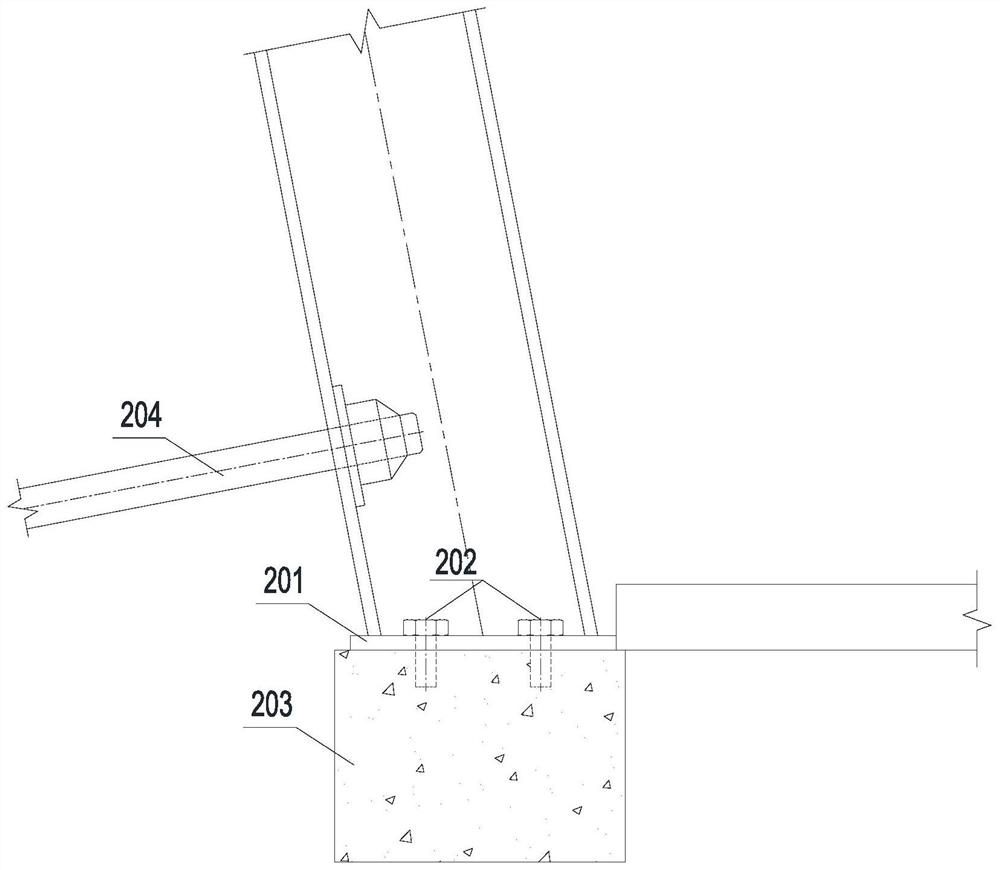

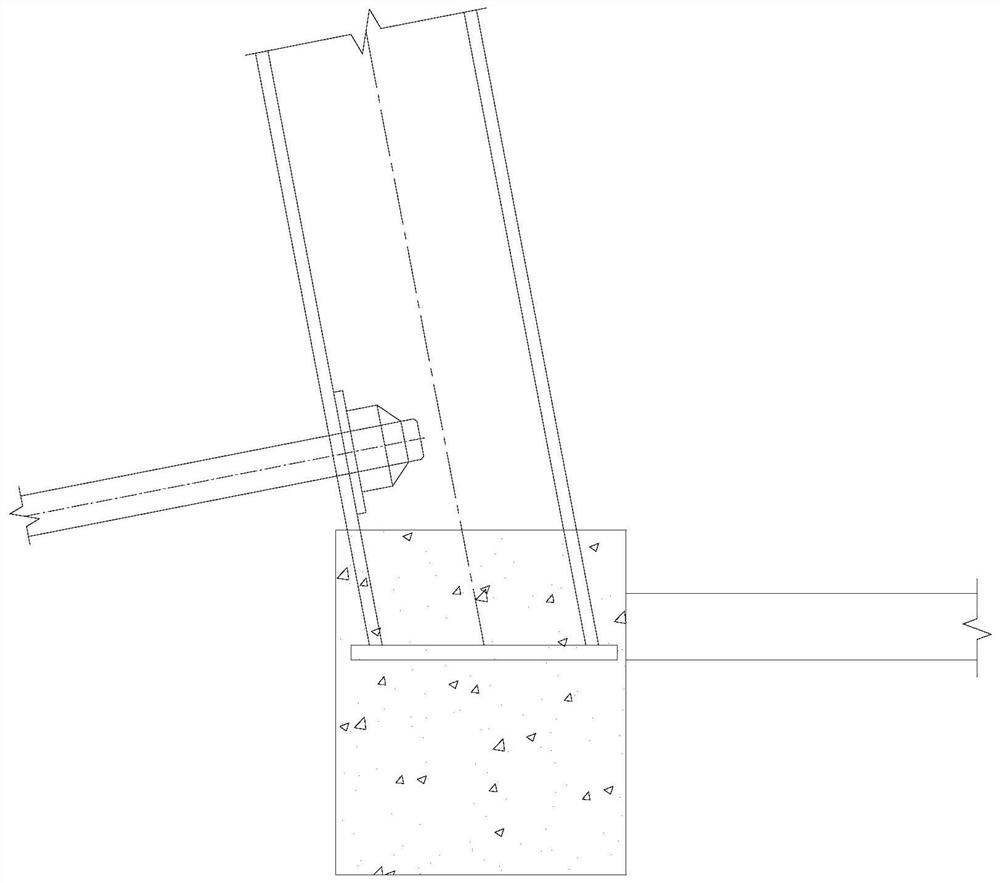

[0060] (3) Prestressed anchor rods are installed at the foot of the steel arch frame and inserted into the surrounding rock of the tunnel through the original lining;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com