A kind of arch reinforcement method suitable for small tunnel clearance

A tunnel and reinforcement technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as complex construction process, long-term traffic impact, long construction period, etc., to reduce construction procedures, construction time, and construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

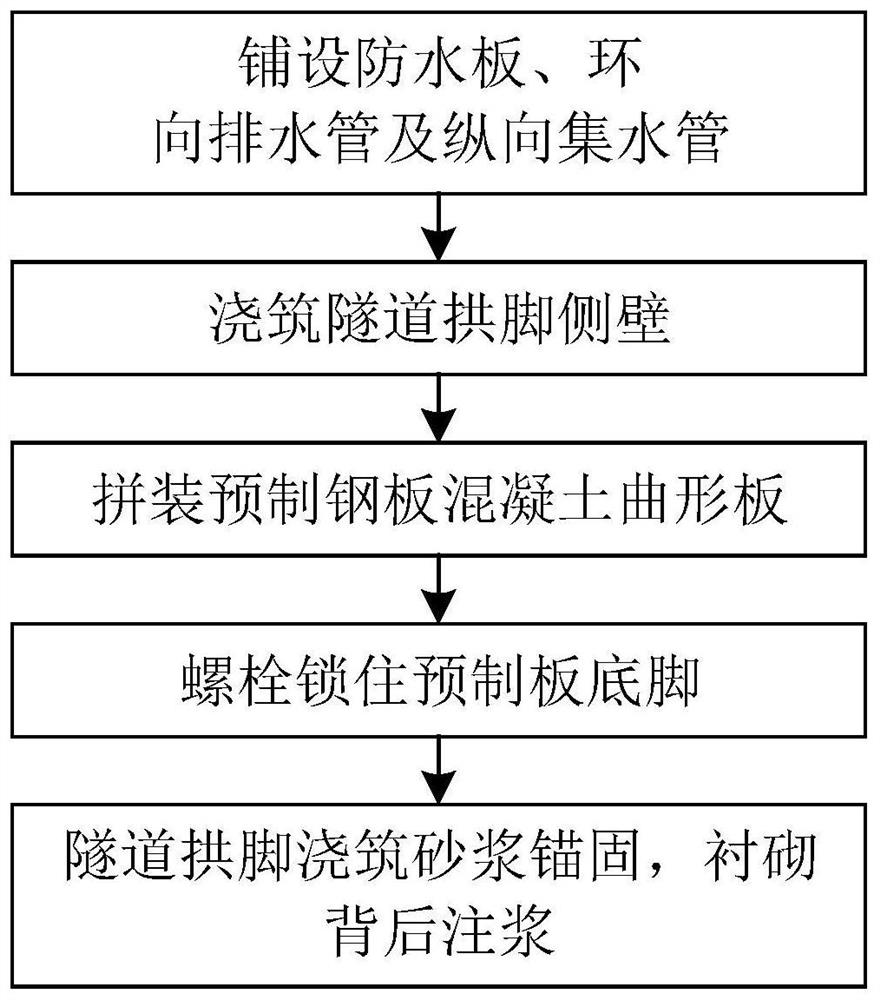

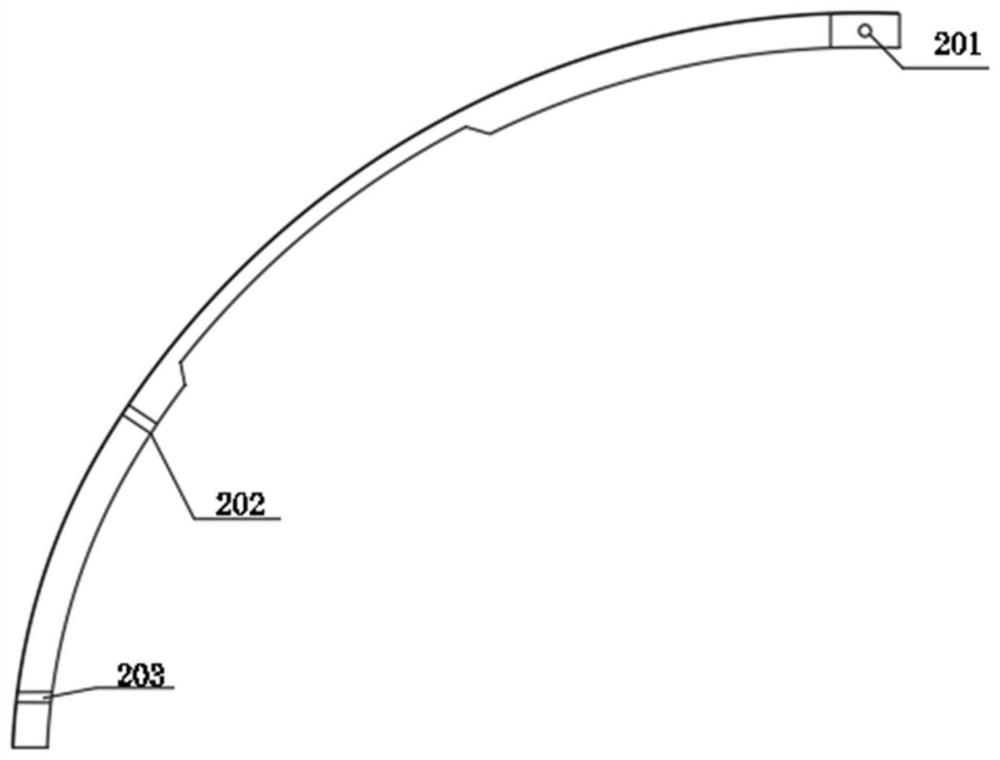

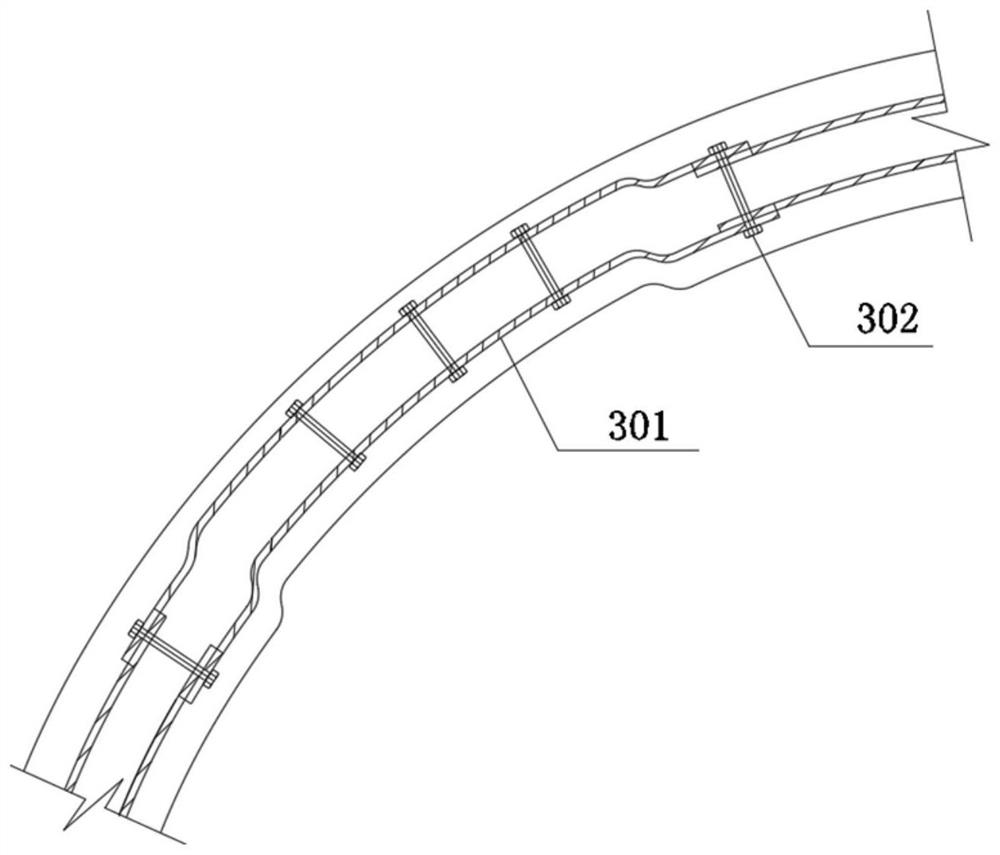

[0042] The invention provides an arch reinforcement method suitable for tunnels with small headroom, which does not need to excavate the tunnel road surface with small headroom, and does not require all roads to be sealed during the construction, pouring and maintenance of the side wall of the tunnel arch foot, which greatly reduces the impact on traffic. The impact is small. This method first lays waterproof boards (in the section with water leakage, lays circular drainage pipes, longitudinal water collection pipes and waterproof boards), and then directly pours side wall baffles on both sides of the tunnel arch foot, and assembles and builds the tunnel arch. Light and thin prefabricated steel plate concrete curved slabs with thinned waist (1 / 2 to 1 / 3 of normal slab thickness to meet the bearing capacity requirements), pouring mortar at the arch foot of the tunnel for anchorage, through light and thin prefabricated steel plate concrete curved slabs Carry out back grouting, lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com