Method for determining coal ignitability

A measurement method and tendency technology, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problem of long test cycle (often ten hours or even dozens of hours, can not reflect the oxidation and spontaneous combustion process in the low temperature oxidation stage, flammable and non-flammable). The problems of inconsistent classification standards of ash-based volatiles have achieved the effect of wide practicability, improved measurement accuracy and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

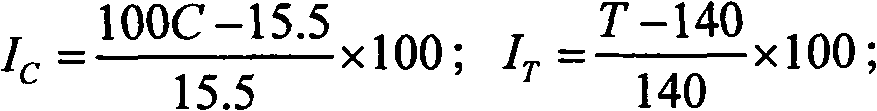

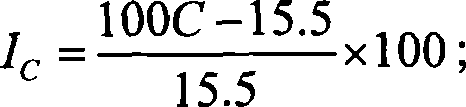

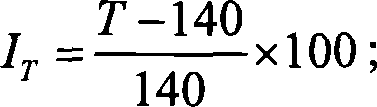

[0019] Example 1: Take coal samples from Changcun Mine in Yima, Henan, and after crushing and screening, take coal samples with a particle diameter of 0.18 mm to 0.38 mm, place the coal samples at 40°C for air drying, and take 50 Put ±0.1g air into the coal sample tank from the dry coal sample, and evenly cover a layer of asbestos with a thickness of 2mm to 3mm above the coal sample. Put the coal sample tank into the test box, feed dry air (oxygen concentration 20.96%) into the coal sample tank at a relatively high and stable flow rate of 96ml / min, and set the temperature of the test box to run at a constant temperature of 40°C. When the temperature of the coal sample reaches 40°C, adjust the dry air flow into the coal sample tank to a lower flow rate of 8ml / min and keep it stable, and set the temperature of the test box to 0.8°C / min. ℃ on the basis of constant temperature operation, the temperature is increased by 0.8 ℃ per minute, and the data collector is turned on at the s...

Embodiment 2

[0025] Embodiment two, take the coal sample of Gequan Mine in Xingtai, Hebei, steps and conditions are the same as embodiment one, omitted. The measured oxygen concentration C was 20.29%. The intersection temperature T is 182.7°C, and the oxygen concentration parameter C and the intersection temperature T are substituted into the calculation formula to obtain the coal spontaneous combustion tendency judgment index I value,

[0026] I=929, 600≤929≤1200, it is determined that the coal in Gequan Mine in Xingtai, Hebei Province is a spontaneous combustion coal seam.

Embodiment 3

[0027] Embodiment three, take the coal sample of Kabuliang mining area, Shizuishan, Ningxia, the steps and conditions are the same as in embodiment one, omitted. The measured oxygen concentration C was 20.72%. The temperature index T of the intersection point is 207.1°C, and the oxygen concentration parameter C and the temperature T of the intersection point are substituted into the calculation formula to obtain the coal spontaneous combustion tendency judgment index I value,

[0028] I=1275>1200, it is determined that the coal in the Kabuliang mining area of Shizuishan, Ningxia is a coal seam that is not prone to spontaneous combustion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com