LED lead frame and method for manufacturing LED using the lead frame

A lead frame and frame technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problem of delamination between the packaging colloid 104 and the reflective cavity 105, the difficulty of product consistency, and the inability to control heat dissipation and assembly density. Compare and other issues to achieve the effect of good product consistency, high production efficiency and high product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Implementation example 1 provides a single-chip LED metal lead frame structure and a method for manufacturing LEDs using the lead frame:

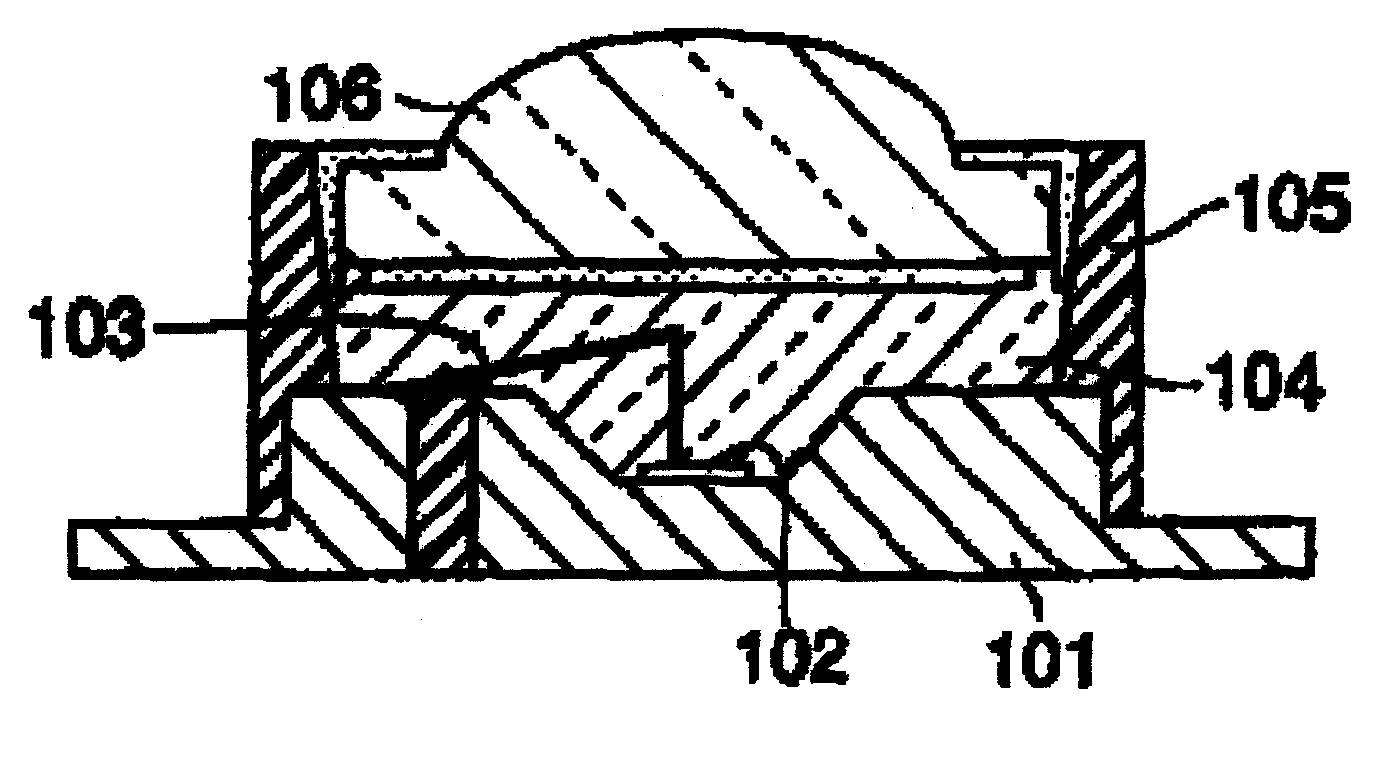

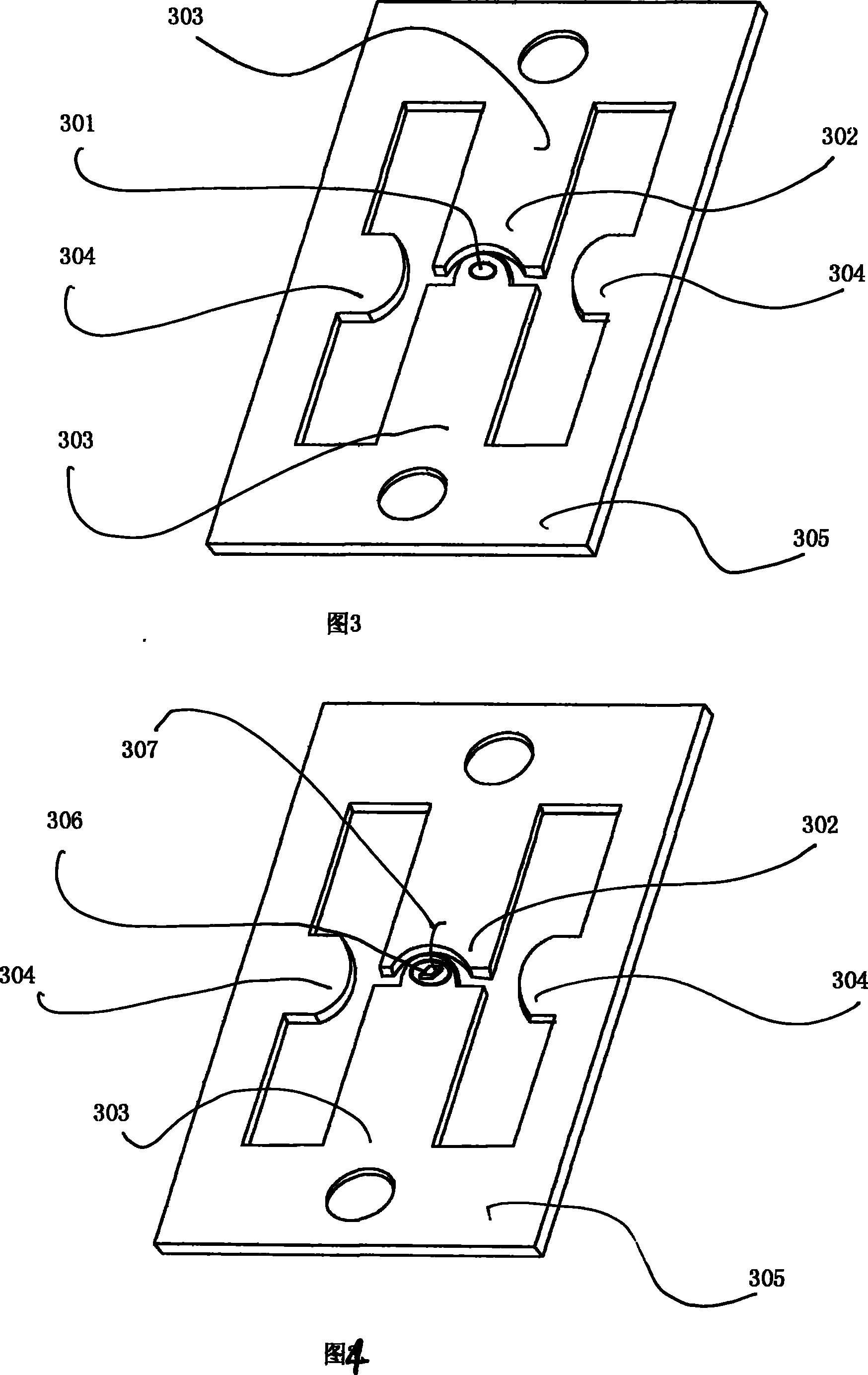

[0031] Such as image 3 The schematic diagram of the preforming of the metal lead frame is shown. The sheet metal plate frame structure with a thickness of 0.3mm is processed into a frame structure composed of convex plates extending toward the middle and spaced from each other in the peripheral frame. The peripheral frame constitutes a connecting substrate. The convex plates The metal lead frame that respectively constitutes several components of the chip placement part 301, the inner lead connection part 302, the outer electrode part 303, the tube body support part 304, and the connection substrate 305; The chip placement part and the chip placement part are located at the front end of the external electrode part, the chip placement part is provided with a reflection cavity, and the chip placement part 301 is provided with a reflec...

Embodiment 2

[0036] Implementation example 2 provides a solution for mass production of lead frames, which is an array structure of 4*10. Schematic such as Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com