Quantitative evaluation method for asepsis filling device outer surface sterilization effect

A quantitative evaluation and aseptic filling technology, applied in biochemical equipment and methods, microbiological-based methods, microbial measurement/inspection, etc., can solve problems such as lack of quantification and difficulty in comparative analysis and evaluation of disinfection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

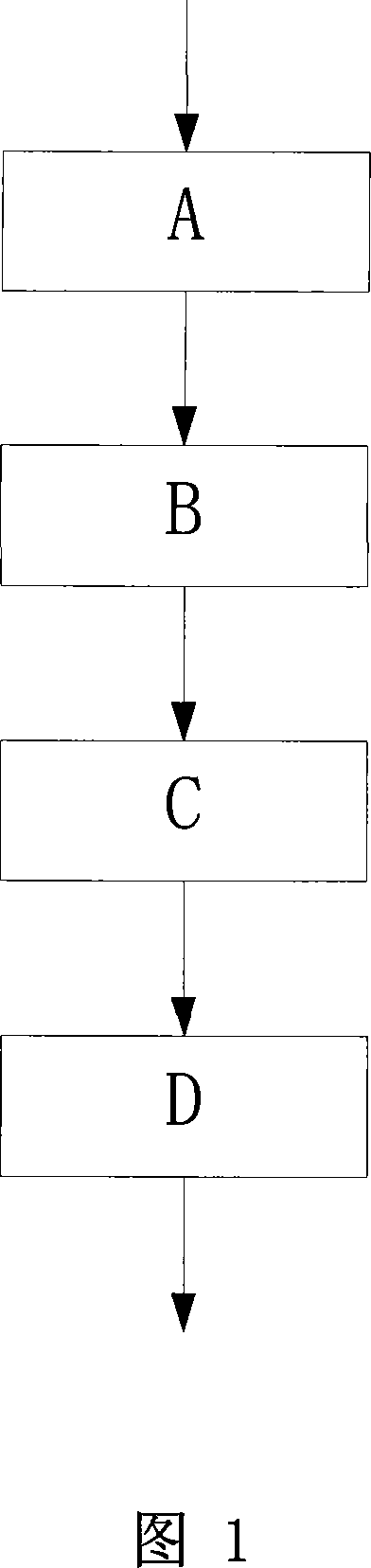

[0020] As shown in Figure 1, the quantitative evaluation method of the disinfection effect of the external surface of the aseptic filling equipment of the present invention consists of the following steps:

[0021] A. Attach the test piece connected with standard microorganisms to the external surface of the equipment to be tested:

[0022] B. Run the disinfection program for the external surface of the equipment;

[0023] C. Collect the residual standard microorganisms on the test piece, cultivate and calculate, and obtain the value of the residual standard microorganisms;

[0024] D. Compare the value of the standard microbial residual amount with the original amount value to obtain the evaluation result.

[0025] In the above step A, the following operations need to be completed:

[0026] 1) Grinding treatment, cleaning and disinfection of the test piece: cut the metal piece with a thickness of 0.1-0.5mm into a test piece with a specification of 25-35mm×55-65mm; Repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com