Special-shaped drum washing machine

A drum-type washing machine and special-shaped drum technology, applied in the field of washing machines, can solve the problems of no major breakthrough in the main structure, heavy drying rotating parts, poor drying function, etc., and achieve easy transmission, small movement resistance, and improved washing efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

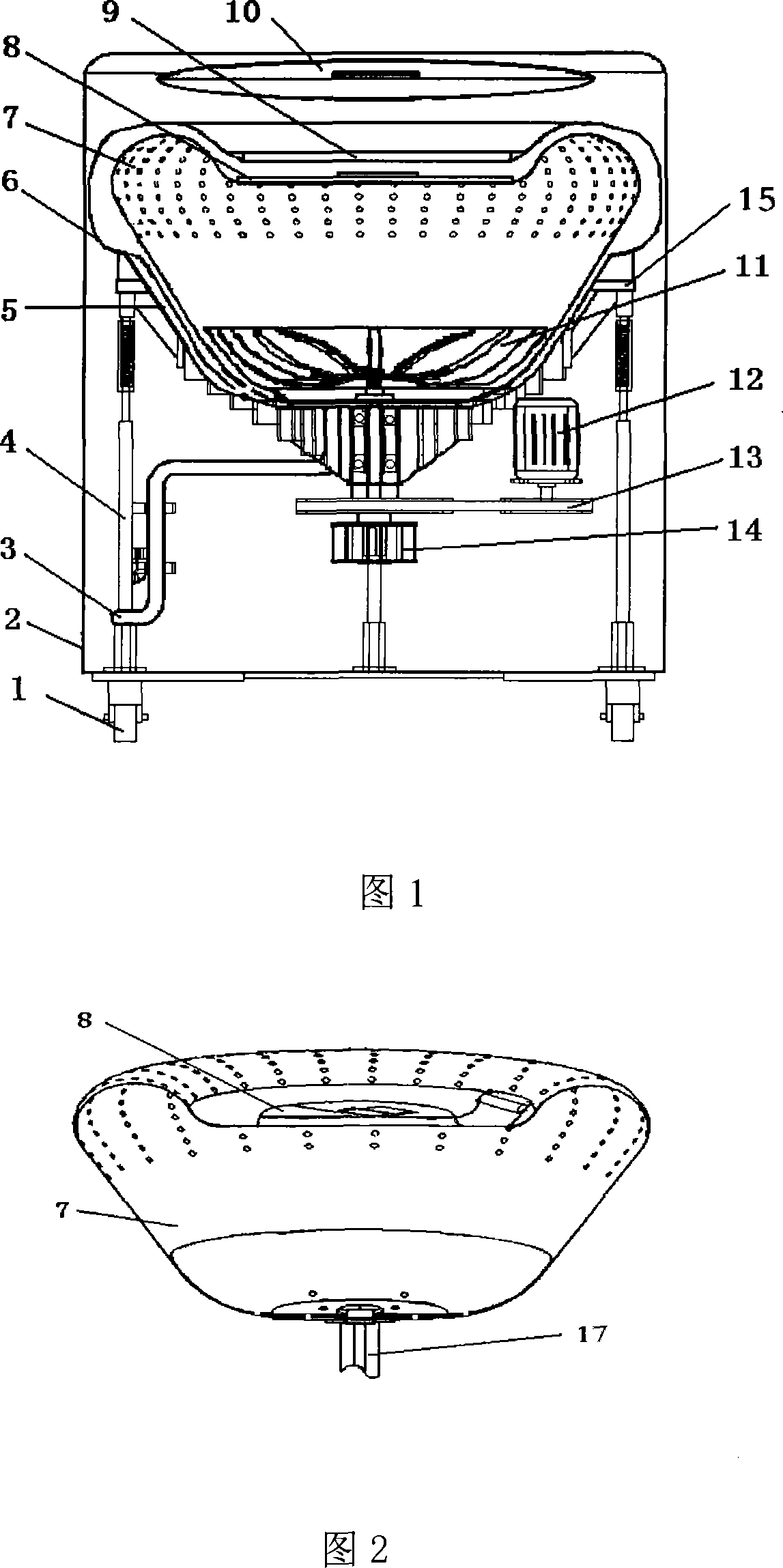

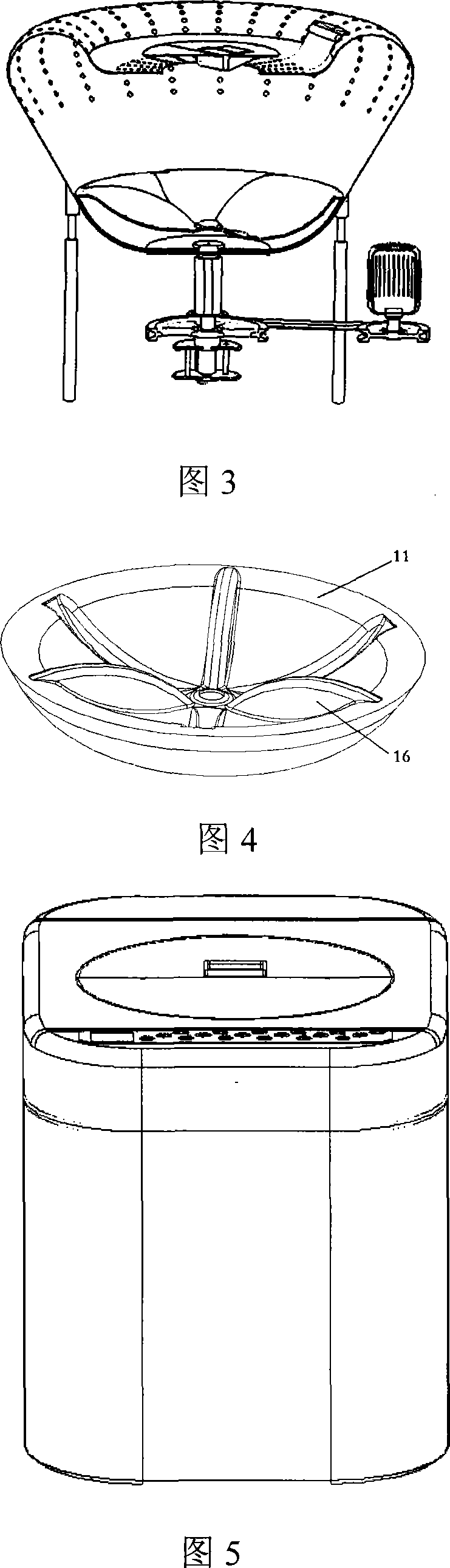

[0024] The structure of the whole machine in this embodiment includes a roller 1, a casing 2, a water outlet pipe 3, an elastic leg 4, a water channel 5, a water tank 6, a special-shaped drum 7, a drum cover 8, a water tank cover 9, a housing cover 10, and a pulsator 11. Motor 12, pulley 13, transmission box 14, lug 15, impeller blade 16 and drum shaft 17.

[0025] The cross-section of the special-shaped drum 7 of this embodiment is ingot-shaped, and its drum generatrix is composed of three sections, the lower section is a semicircular arc, the middle section is a cone of 30°-40°, and the upper section is an inverting arc type ring shape, When running at high speed, it carries clothes; the upper part of the drum 7 is provided with holes to facilitate the liquid to be thrown out during centrifugal washing; the bottom is also provided with holes to ensure that the washing liquid enters the drum 7 normally; The shaft of the pulsator 11 is installed inside, and the pulsator 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com