Large power solid-state illumination street light fitting

A solid-state lighting, high-power technology, applied in fixed lighting devices, outdoor lighting, energy-saving lighting, etc., to achieve the effect of low operating temperature, lower overall operating temperature, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

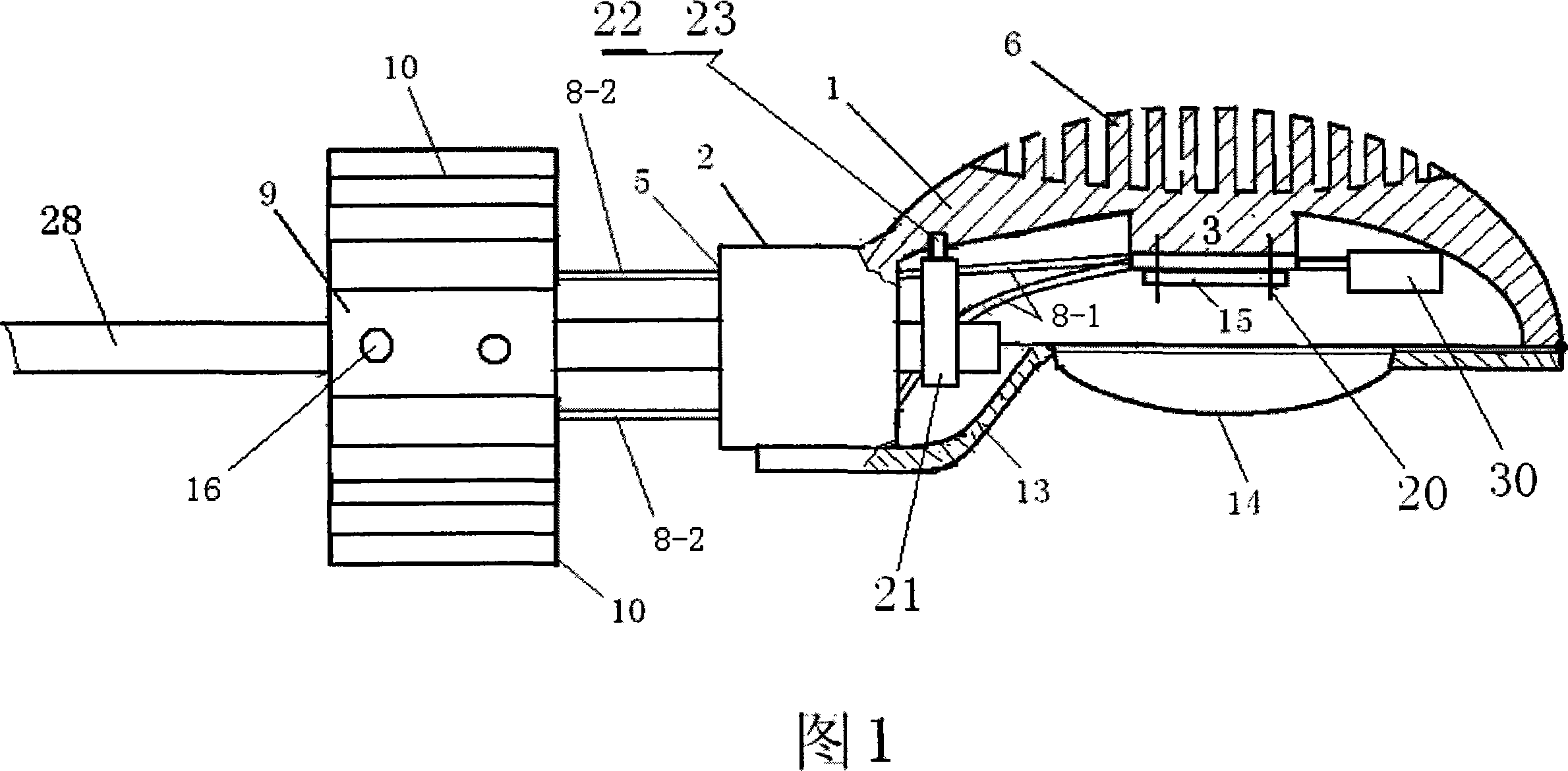

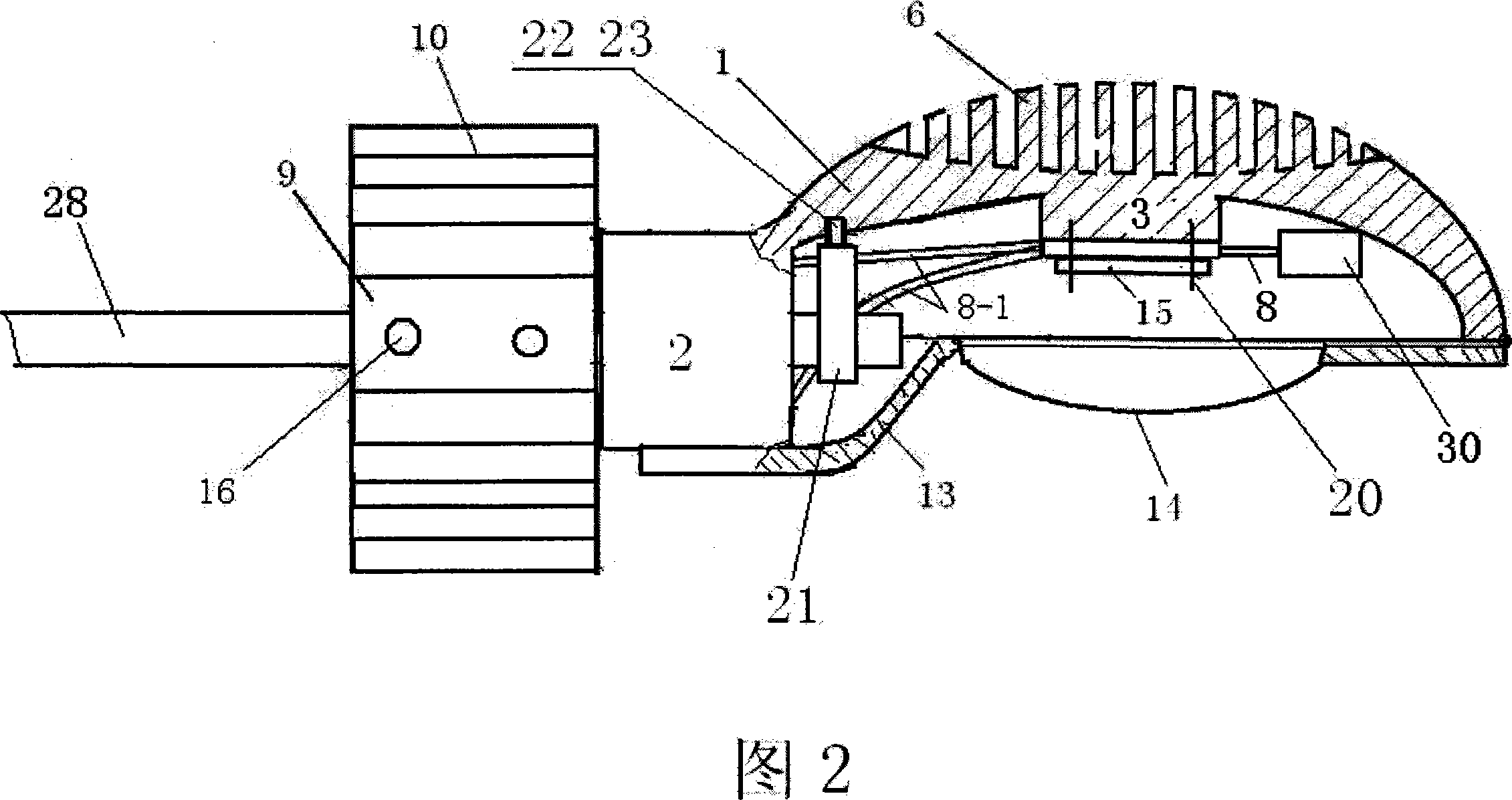

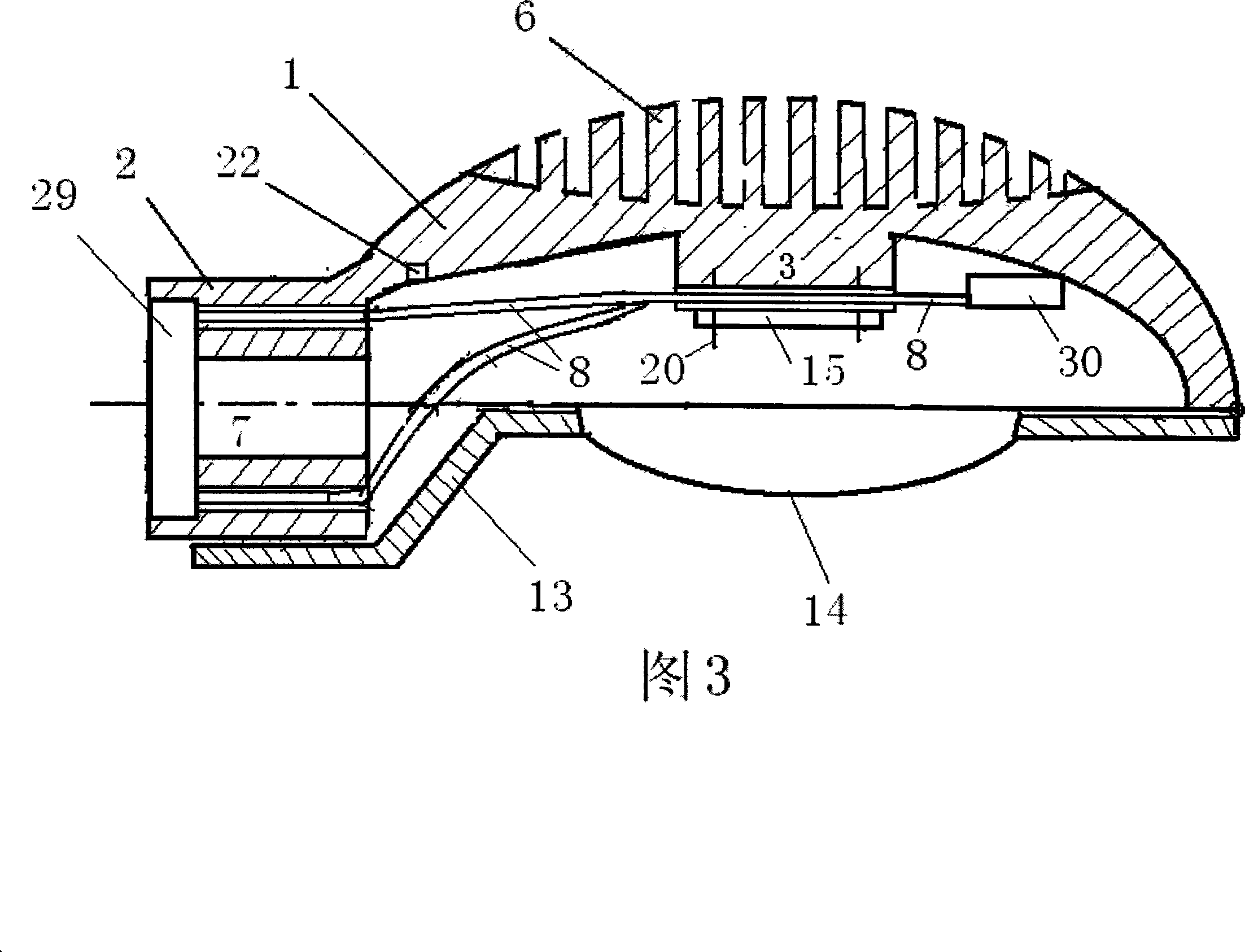

[0013] The high-power solid-state lighting street lamp of the present invention is completed by connecting, combining, installing and fixing the main shell, lampshade, LED lamp, heat pipe, external radiator, power supply device, etc. by using the prior art methods.

[0014] Specific combined installation: including the main shell of the lamp, the lampshade, the LED lamp, the external heat sink, the components of the LED power supply unit, the main shell of the lamp (1), the heat pipe connector (2), the LED lamp holder (3), the heat pipe (8), in the heat dissipation component (6), the heat pipe at one end of the main housing is connected to the connector (2), the heat pipe at one end of the heat pipe connector (2) is connected to the LED lamp holder (3), and the heat pipe connector (2) ) is connected to the external heat sink; the heat pipe (8) on the LED lamp holder (3) is closely combined with the substrate or tight base of the LED lamp to quickly remove the heat of the LED. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com