Anti-deformation foot roll combination device for bloom segment and its application method

A technology of combined device and application method, applied in the field of metallurgy, can solve the problems of decreasing the number of continuous casting furnaces, increasing the production cost, reducing the amount of steel passing through the continuous casting machine, and achieving the effect of long service life and non-deformed service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

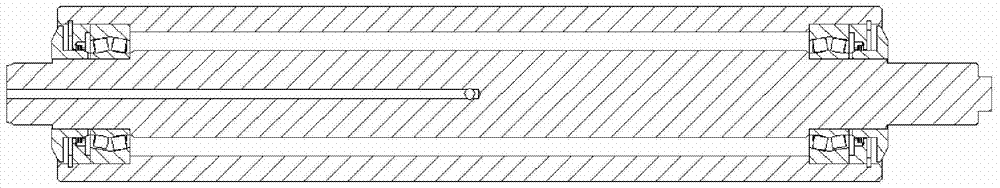

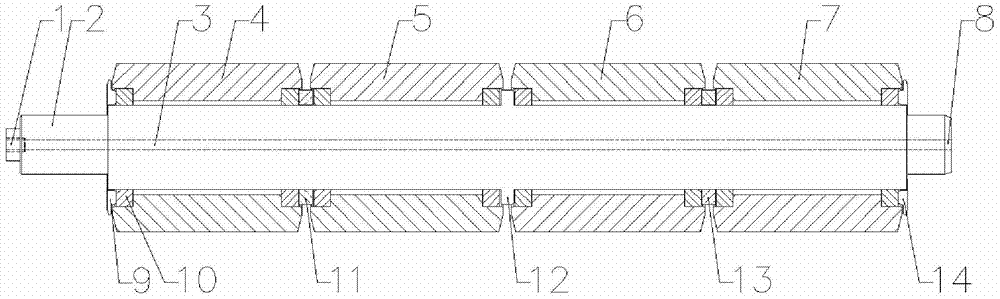

[0025] This embodiment provides an anti-deformation foot-roll combination device for a sector of a bloom, the structure of which is as follows: figure 2 As shown, including the central axis 2, a through hole 3 is provided at both ends of the entire central axis 2 with the center line of the central axis 2 as the center. The through hole 3 includes a water inlet 1 and a water outlet 8, and the water inlet 1 is provided with a For the screw hole of the water pipe, the end of the central axis 2 near the water inlet 1 is provided with a first end cover 9, and the end of the central axis 2 near the water outlet 8 is provided with a second end cover 14, and the first end cover The first foot roller 4, the second foot roller 5, the third foot roller 6 and the fourth foot roller 7 are sequentially nested between the plate 9 and the second end cover plate 14, and the first foot roller 4 and the second foot roller A first positioning ring 11 is installed at the junction of 5, a collar ...

Embodiment 2

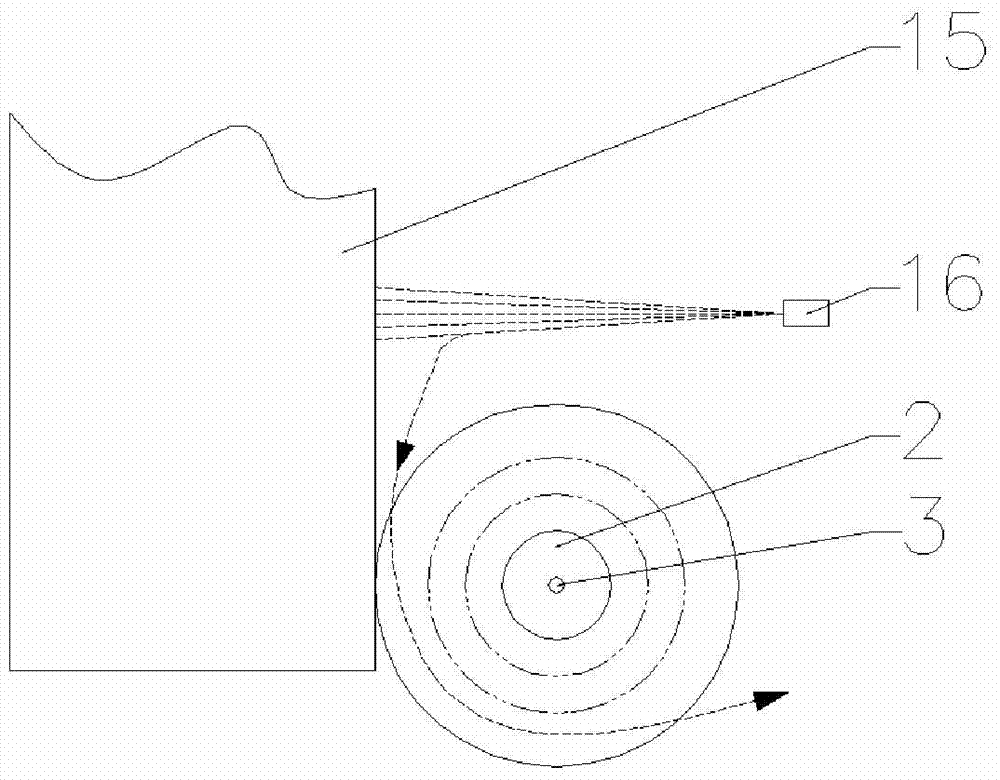

[0029] This embodiment provides an invention and also provides an application method of the anti-deformation foot-roller combination device of the sector of the bloom, such as image 3 As shown, the specific method is as follows:

[0030] When the slab leaves the crystallizer, it enters the foot roll combination device, and the four small foot rolls rotate freely through self-lubricating bearings;

[0031] Install the water pipe through the screw hole at the water inlet 1, and pass cold water into the through hole 3 to cool the central shaft 2, and the water in the through hole 3 finally flows out from the water outlet 8;

[0032] Open the secondary cooling water nozzle 16 to carry out secondary cooling to the slab;

[0033] The secondary cooling water is shot vertically at the slab, and part of the water and water vapor pass through the gaps between the four small foot rolls. At the same time, the secondary cooling water contacts the slab and is also vaporized into steam, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com