Joint with increased splay angle

A technology of external joints and constant velocity universal joints, applied in the direction of connection, elastic coupling, extracellular fluid disease, etc., can solve problems such as track edge damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

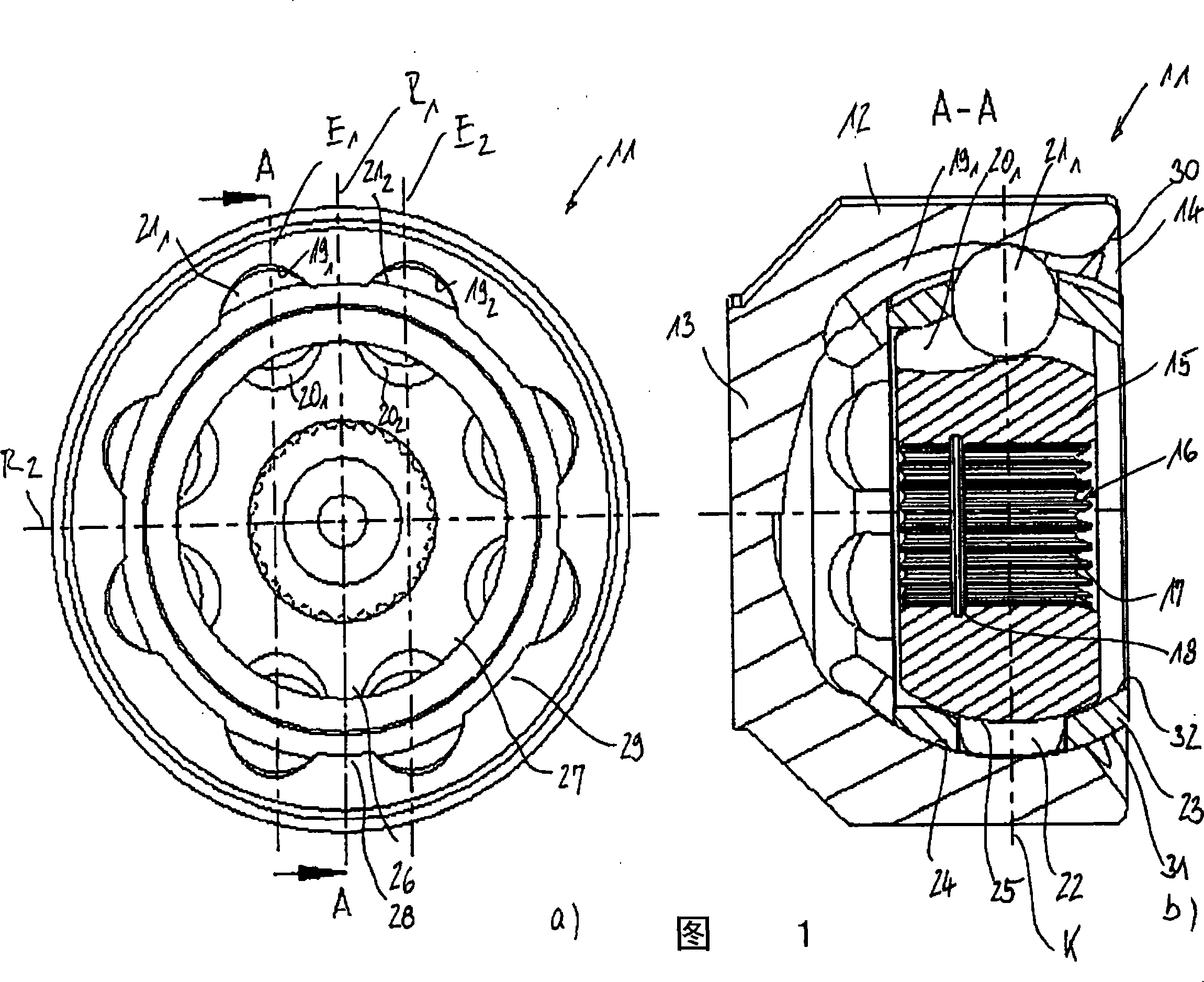

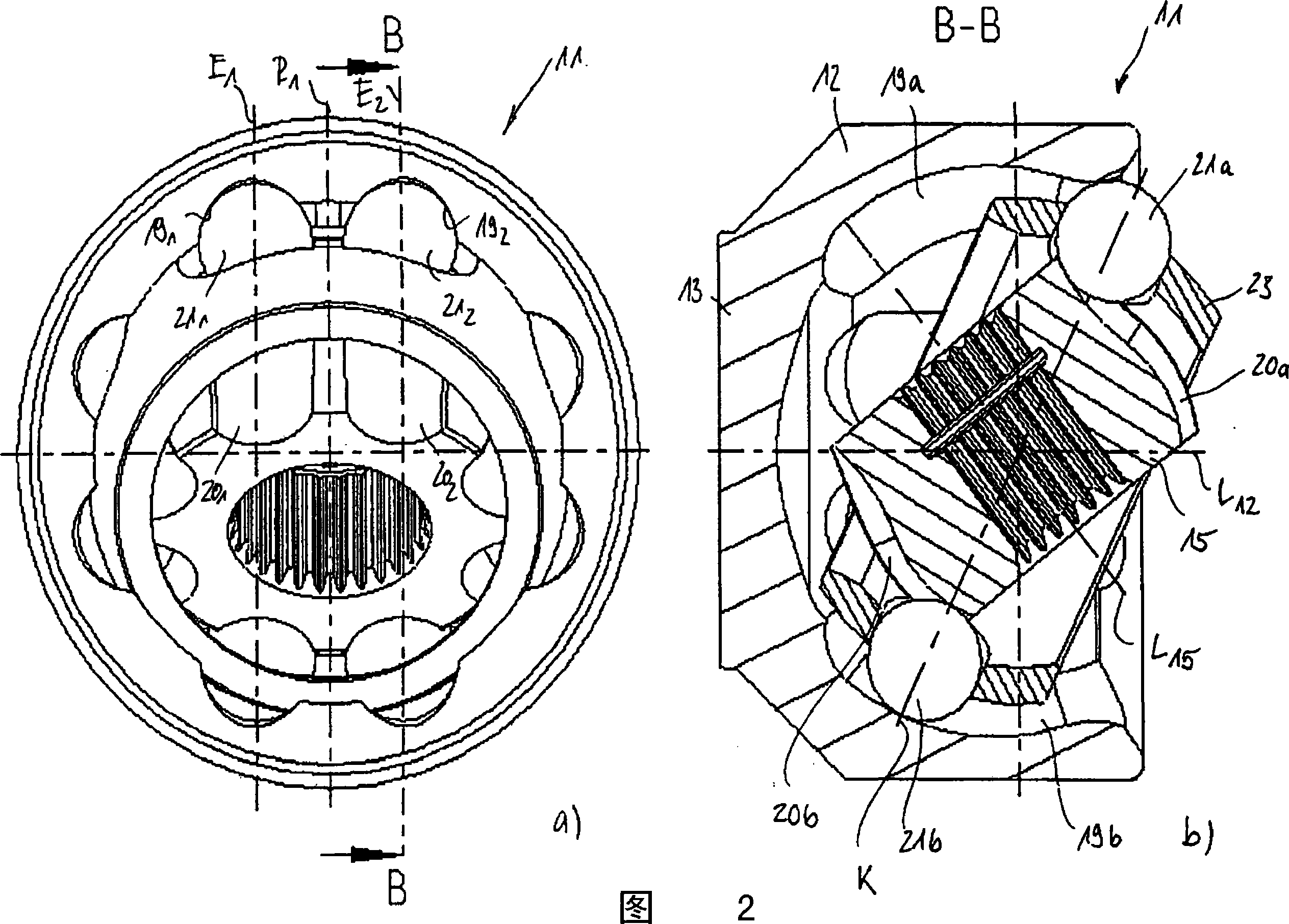

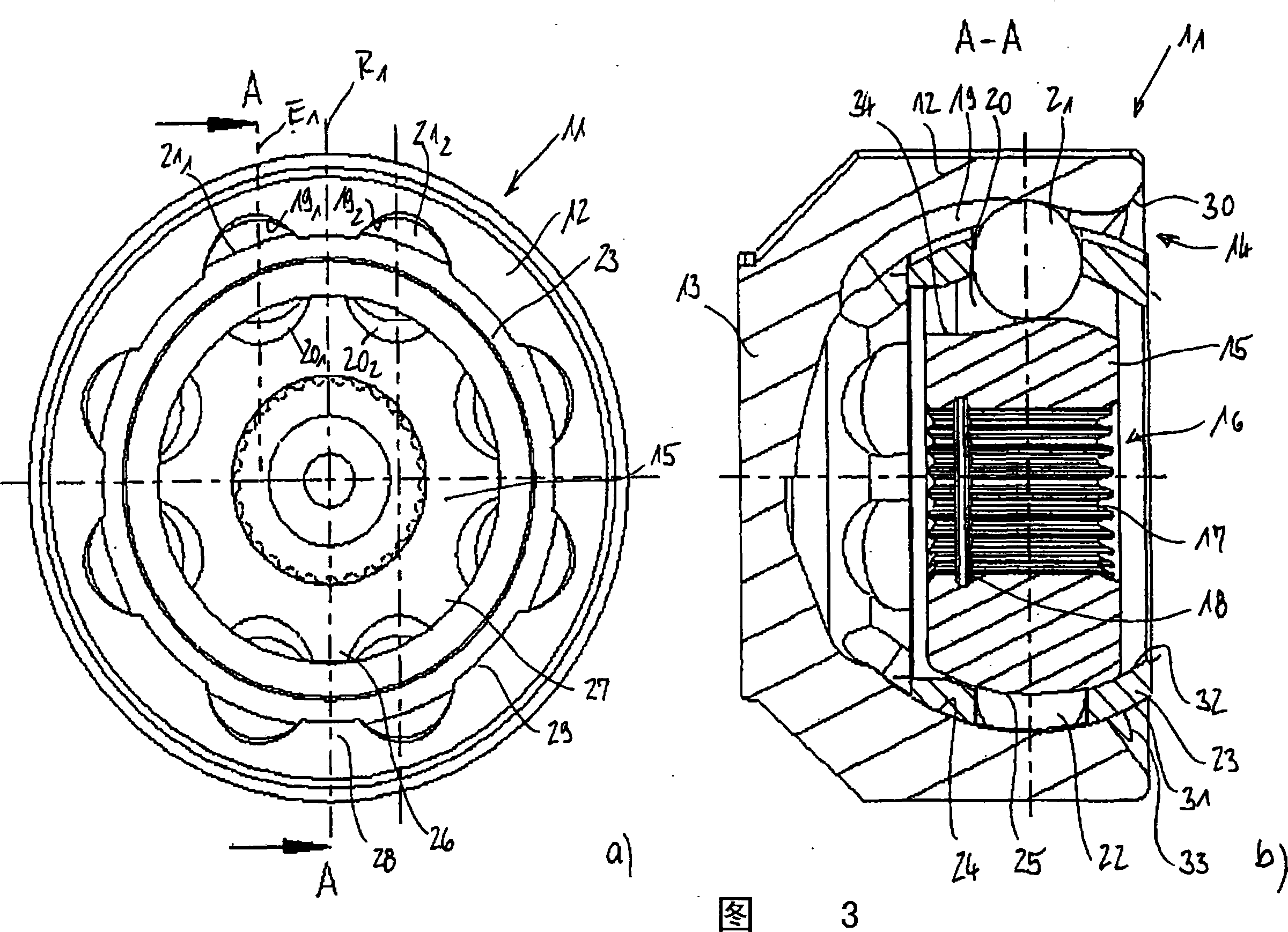

[0028] The two diagrams in FIG. 1 will be jointly described below. The figure shows a so-called double ball joint in which the longitudinal extension of adjacent pairs of rails is defined by parallel planes. Using a total of eight circumferentially distributed balls, two pairs of parallel planes can be determined as the geometrical position of the centerline of the track. Two planes E1 , E2 are marked with dotted lines, which are located symmetrically with respect to the first radial plane R1 . A second radial plane R2 is positioned perpendicularly to the first radial plane R1, the plane of the associated ball track extending parallel thereto is not shown here. The constant velocity universal joint 11 comprises an outer joint member 12 having a bottom 13 formed thereon with an opening 14 of the joint positioned axially opposite the bottom 13 . Located in the outer joint part 12 is an inner joint part 15 which has an insertion opening 16 showing internal teeth 17 for introduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com