Section hole rotation plate type rice bowl dish precision seeding machine

A seeder and rotary plate technology, applied in planting methods, seed treatment methods, applications, etc., can solve the problems of high void rate and gram-seed rate, low seed filling rate, and large seed waste, so as to reduce the void rate and gram seed rate, high operating efficiency, and the effect of saving seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

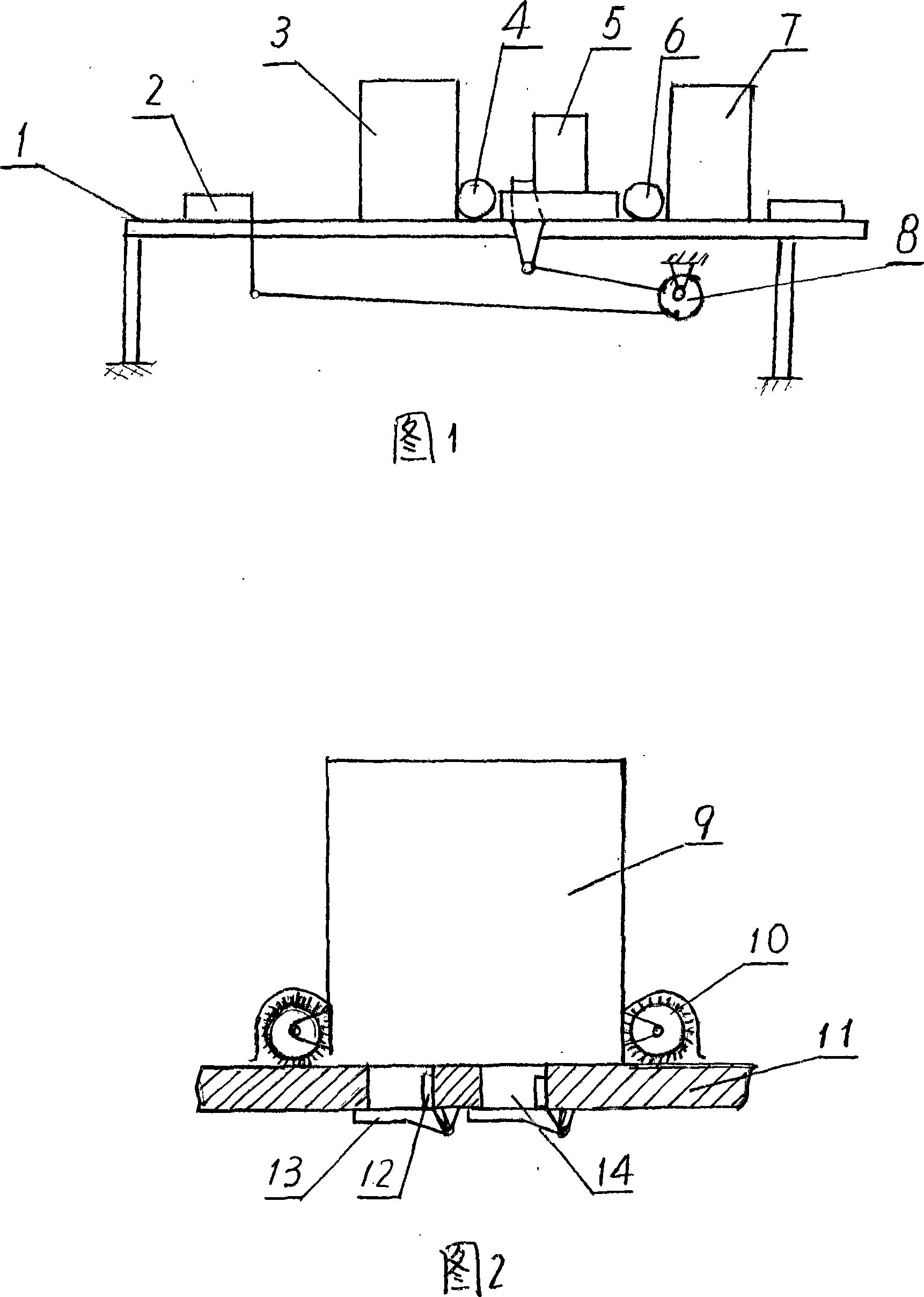

[0010] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. The type hole rotating plate type precision seeder for rice bowls and discs includes a frame assembly 1 and a pusher 2 mounted on the frame assembly 1, a subsoil laying device 3, a subsoil compacting roller 4, and a seed box 9 and A seeder 5, a light pressure roller 6, a topsoil layer 7 and an eccentric drive mechanism 8 composed of a type orifice plate 11, the single-layer orifice plate 11 of the seeder 5 is fixed on the frame assembly 1, and the single-layer orifice plate On the 11 upper plane, the fitting kind casing 9 that can longitudinally reciprocate, the self-rotating type clearing kind of hairbrush wheel 10 is fitted on the outside of the kind casing 9 left and right side walls, the self-rotating type clearing kind of kind hairbrush wheel 10 and the single The upper surface of the layer-type orifice plate 11 is in contact with the plane;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com